CJD

Yoda

Offline

It is now 2 years and nine months since I low balled the PO and got my TR2 project. For this entire time I have been dreading the bodywork, since I knew the body was abysmal. Well, yesterday it began. I figured Pigot says the restoration begins at the doors, so that is where I started.

Yep. It's bad.

Here are a few pics. I have 4 doors to pick from. The originals are actually relatively good as far as rust, but have significant body damage from at least 2 previous accidents. The second pair have minimal damage, but are holed with rust.

This is the first of the original doors. I used a torch to heat the bondo and scraped a good hour to get it off. The PO loved Bondo, and "put that S&%t on everything", to quote the add!

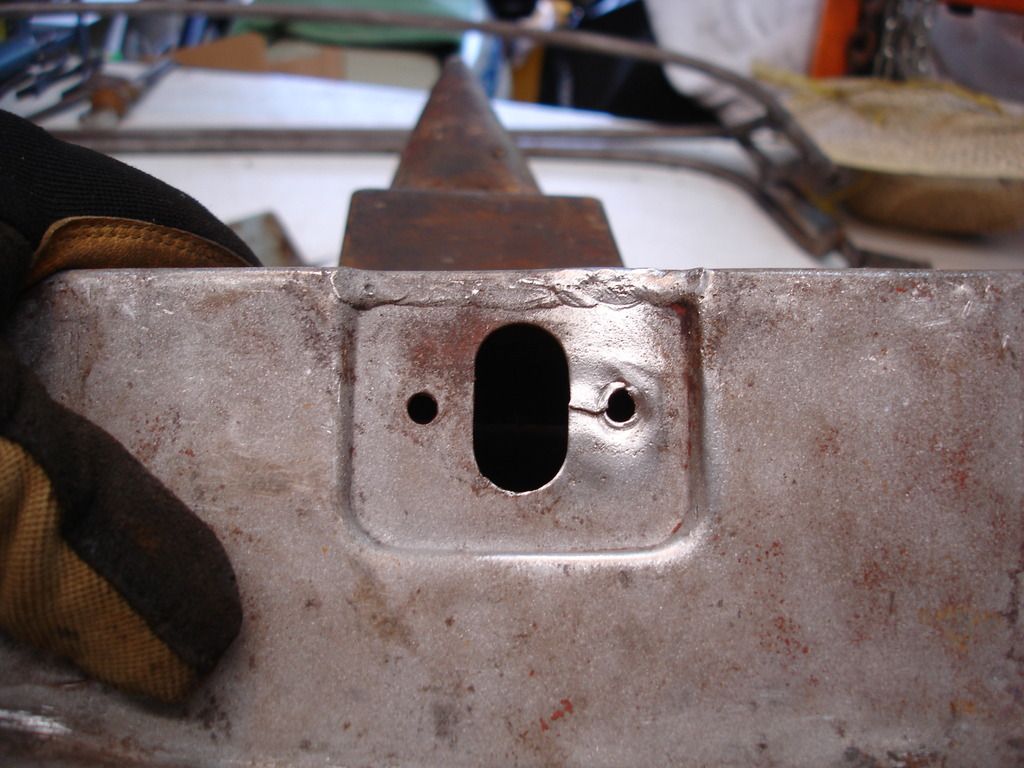

Below the bondo was the evidence of the earlier accident...lead. More heat and a puddle of lead on the floor got me down to the basics. Unfortunately, the basics weren't that good. I decided the frames all need the lower rail replaced, so the obvious step is to separate the frames from the skins.

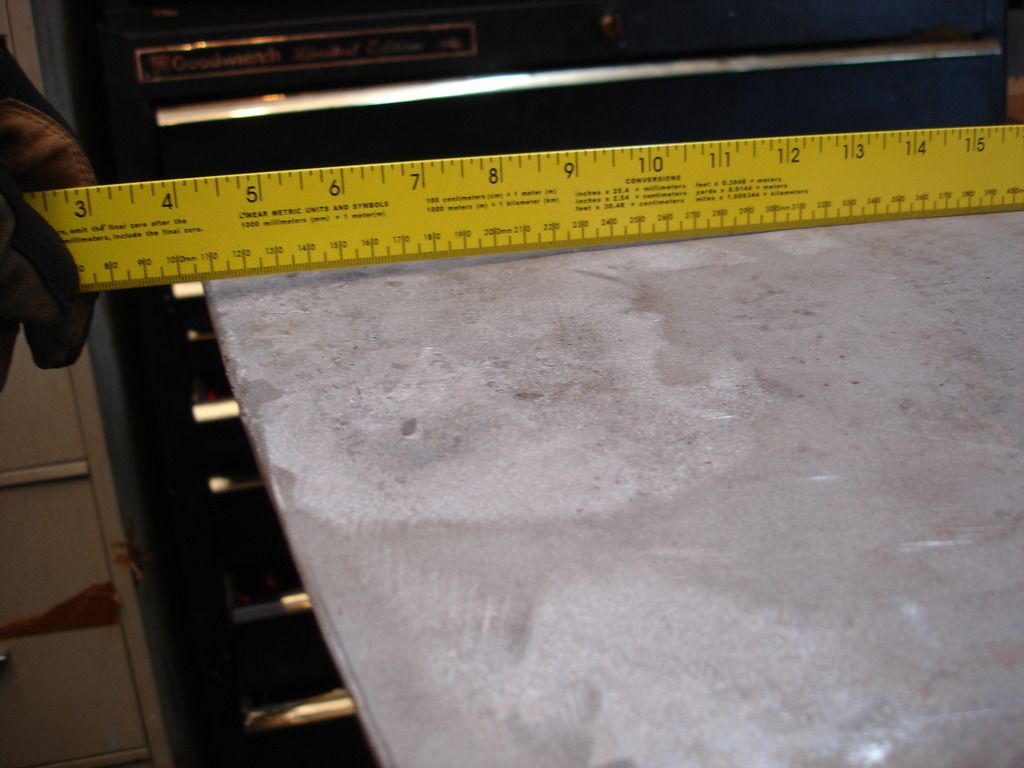

The skins are just wrapped around the edge of the frame, and then tack welded at about 4 spots per side. A little work with a dremel broke the tack welds. Usually, when you take off a skin you have no plan to re-use it. If that is the case, all you have to do is grind the crimped edge and the skin pops right off. Being in the position of having to re-use makes the job much more difficult. The crimped edge has to be preserved. Bummer.

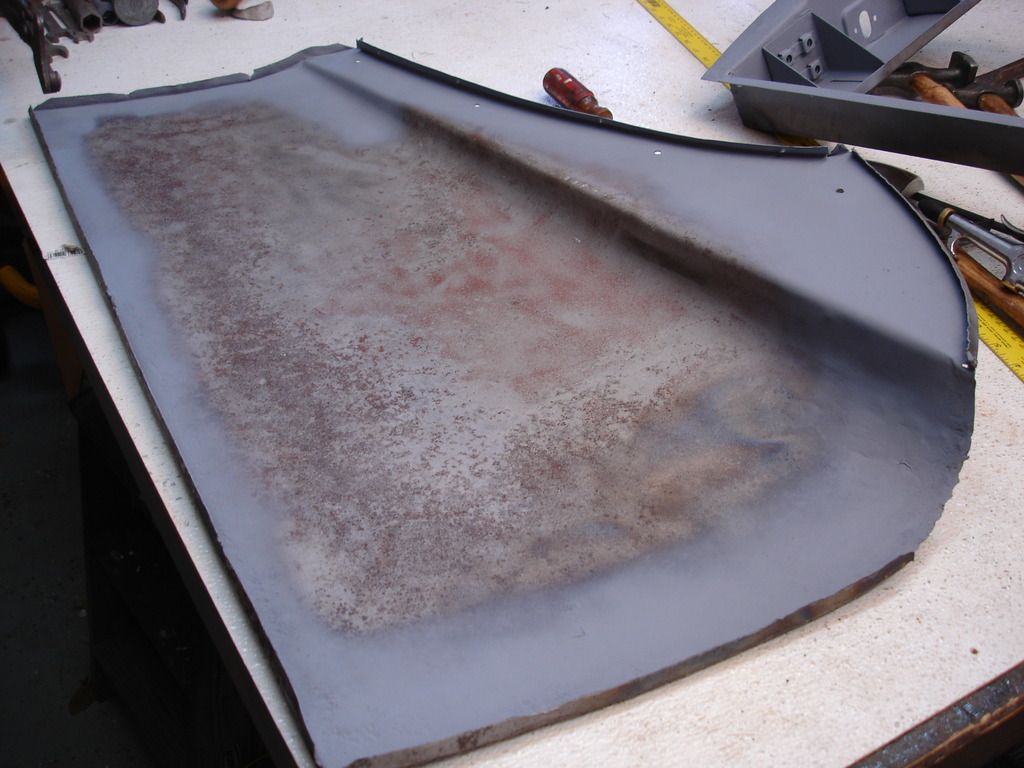

And a whole lotta work with a chisel and crow bar to free the edge, and the skins are off.

Finally...some hammer and dolly work to true up the skin edges. I'm finally back to a job I am familiar with.

To ensure the bondo stayed on, the PO drilled holes in the skins.

So all the holes have to be filled. This is a little ruby tipped torch and a mild steel rod. When hammered while red hot, the holes will disappear. Funny, that sounds easy...but it takes a whole lotta hammering and heating before it happens.

I am including this as a warning to those that follow. I run into this regularly, and it truly sucks. Once you braze a panel, it is a real PITA to remove it to do correct repairs later. I have to heat all this mess to the melting point of the bronze, but below the steel and then smack the panel on the table to get the mess off. If you braze body work, there will be someone like me cussing about it in the future. There is no place for brazing with bronze in body work. In this pic you can see where the wing was jammed into the top of the door frame. Normally this area would have a gently rounded curve...instead it is dented in and ripped open. Rather than fixing it...the shop just brazed the edge of the door that shows, to stiffen it up. The damage would still be very obvious when the door is open, and it likely took the tech longer to braze than it took me to fix it right...once the bronze was removed.

So, just a taste. This is going to be a huge project. New skins are $200 ea...so I'll pass on that option. The frames have to be repaired from the bottom up, and beat back to shape. I'm tired of trying to find decent doors to start with...so these will have to do. Bummer.

One of the biggest issues on the TR3 was getting the contour of the doors to match the wing in the front and quarter panel in the back. Since the skins are off, I will try to simplify this job by contouring the doors to match AS the skins go back on. The door assemblies are flimsy when separated, so it should be possible to match the contours without much trouble...and then lock the skins down to tighten everything back up. I'll let everyone know if this idea works or not.

Yep. It's bad.

Here are a few pics. I have 4 doors to pick from. The originals are actually relatively good as far as rust, but have significant body damage from at least 2 previous accidents. The second pair have minimal damage, but are holed with rust.

This is the first of the original doors. I used a torch to heat the bondo and scraped a good hour to get it off. The PO loved Bondo, and "put that S&%t on everything", to quote the add!

Below the bondo was the evidence of the earlier accident...lead. More heat and a puddle of lead on the floor got me down to the basics. Unfortunately, the basics weren't that good. I decided the frames all need the lower rail replaced, so the obvious step is to separate the frames from the skins.

The skins are just wrapped around the edge of the frame, and then tack welded at about 4 spots per side. A little work with a dremel broke the tack welds. Usually, when you take off a skin you have no plan to re-use it. If that is the case, all you have to do is grind the crimped edge and the skin pops right off. Being in the position of having to re-use makes the job much more difficult. The crimped edge has to be preserved. Bummer.

And a whole lotta work with a chisel and crow bar to free the edge, and the skins are off.

Finally...some hammer and dolly work to true up the skin edges. I'm finally back to a job I am familiar with.

To ensure the bondo stayed on, the PO drilled holes in the skins.

So all the holes have to be filled. This is a little ruby tipped torch and a mild steel rod. When hammered while red hot, the holes will disappear. Funny, that sounds easy...but it takes a whole lotta hammering and heating before it happens.

I am including this as a warning to those that follow. I run into this regularly, and it truly sucks. Once you braze a panel, it is a real PITA to remove it to do correct repairs later. I have to heat all this mess to the melting point of the bronze, but below the steel and then smack the panel on the table to get the mess off. If you braze body work, there will be someone like me cussing about it in the future. There is no place for brazing with bronze in body work. In this pic you can see where the wing was jammed into the top of the door frame. Normally this area would have a gently rounded curve...instead it is dented in and ripped open. Rather than fixing it...the shop just brazed the edge of the door that shows, to stiffen it up. The damage would still be very obvious when the door is open, and it likely took the tech longer to braze than it took me to fix it right...once the bronze was removed.

So, just a taste. This is going to be a huge project. New skins are $200 ea...so I'll pass on that option. The frames have to be repaired from the bottom up, and beat back to shape. I'm tired of trying to find decent doors to start with...so these will have to do. Bummer.

One of the biggest issues on the TR3 was getting the contour of the doors to match the wing in the front and quarter panel in the back. Since the skins are off, I will try to simplify this job by contouring the doors to match AS the skins go back on. The door assemblies are flimsy when separated, so it should be possible to match the contours without much trouble...and then lock the skins down to tighten everything back up. I'll let everyone know if this idea works or not.

Hi Guest!

Hi Guest!

smilie in place of the real @

smilie in place of the real @

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

Pretty Please - add it to our Events forum(s) and add to the calendar! >>