Offline

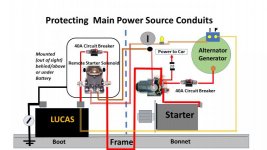

Basically a circuit is a loop so aside from an overriding authority or governing body making a regulation you can put a fuse in the loop anywhere and if it opens due to overcurrent or short circuiting (which will create the overcurrent) it will stop the current flow. In automobile technology there is very little governing body that regulates what you do. All current going out of the battery has to return to the battery or it would not work at all.

Ok, having said all that, what happens to the potentially large amounts of current that the generator or alternator might put out if the battery cable between the solenoid and the battery were dead shorted. I have a pretty good electrical background having studied it in technical school and as a career electrician and a Metering tech for a large utility. I was the guy responsible to measure all types of power in the largest electrical installations in place. From generating stations to large industrial complexes. So, I really don't know the answer to my own question. It would take some studying of the components involved and some test measurements. But here is a possibility: In my first paragraph I described a simple loop with one power source, the battery. But if the alternator takes over and its cable is shorted then the alternator becomes the overriding power source. Forget about the generator, Austin Healey generators can't put out that much before they will just burn up their brushes and commutators. Since the alternator is also grounded to the car chassis, the circuit loop is now from the alternator BAT terminal down to the solenoid and continuing down the path to the battery until it reaches the point of short circuit. That would be the large cable shorted to the chassis. So here we have an alternator that is in a loop that has its BAT terminal shorted to the chassis and then continuous to the ground side of its own windings. A continuous loop and a short one with almost zero resistance. The alternator will try to go to max output.

The battery is almost completely out of the circuit so a fuse protection back at the battery will not stop the alternator from going to max and trying to feed the shorted loop. Now if the short in the electrical system is on any of the smaller wires, those wires will just burn apart and as some have said, will act like a fuse. They will burn open and the circuit will be open and the alternator will stop putting out. Could the small wires burn enough to cause a fire, they could. But that is why we are putting fuses on all our circuits.

But back to the large cable that could get shorted to the chasis. How do we stop that cable from really pulling a heavy current from the alternator? In previous post, I have said, it just doesn't happen don't worry about it. Well I'm still playing those odds, but, is there a way to protect that large cable. There is. You would have to design an installation that would fit, but the equipment and technology does exist. It's called a 'CT'. Stands for "Current Transformer". This is a transformer that step up or steps down Current. Not Voltage. We all experience Voltage Transformers because they are around us every day. The utility uses voltage transformer to step down the high voltage to the voltage (120/240v) usually to your house. Your door bell works off a voltage transformer, it takes the 120volts in the house circuit and steps it down to 12, 18 or sometimes 24 volts. But a CT steps CURRENT up or down and has almost no parasitic loss doing it.

Do you see where I am going with this. If a Ct could be installed around the large cable going to the battery, it could trigger a relay when the large cable reaches a current value of a specified threshold.

here is an example of what I am talking about but you would have to find one that had the right specifications. the large cable runs thru the center of this and the device senses the current in the cable.

I see two problems with this. 1. I still think it is cumbersome. 2. I don't know that it would react fast enough to avoid a catastrophic loss.

Ok, having said all that, what happens to the potentially large amounts of current that the generator or alternator might put out if the battery cable between the solenoid and the battery were dead shorted. I have a pretty good electrical background having studied it in technical school and as a career electrician and a Metering tech for a large utility. I was the guy responsible to measure all types of power in the largest electrical installations in place. From generating stations to large industrial complexes. So, I really don't know the answer to my own question. It would take some studying of the components involved and some test measurements. But here is a possibility: In my first paragraph I described a simple loop with one power source, the battery. But if the alternator takes over and its cable is shorted then the alternator becomes the overriding power source. Forget about the generator, Austin Healey generators can't put out that much before they will just burn up their brushes and commutators. Since the alternator is also grounded to the car chassis, the circuit loop is now from the alternator BAT terminal down to the solenoid and continuing down the path to the battery until it reaches the point of short circuit. That would be the large cable shorted to the chassis. So here we have an alternator that is in a loop that has its BAT terminal shorted to the chassis and then continuous to the ground side of its own windings. A continuous loop and a short one with almost zero resistance. The alternator will try to go to max output.

The battery is almost completely out of the circuit so a fuse protection back at the battery will not stop the alternator from going to max and trying to feed the shorted loop. Now if the short in the electrical system is on any of the smaller wires, those wires will just burn apart and as some have said, will act like a fuse. They will burn open and the circuit will be open and the alternator will stop putting out. Could the small wires burn enough to cause a fire, they could. But that is why we are putting fuses on all our circuits.

But back to the large cable that could get shorted to the chasis. How do we stop that cable from really pulling a heavy current from the alternator? In previous post, I have said, it just doesn't happen don't worry about it. Well I'm still playing those odds, but, is there a way to protect that large cable. There is. You would have to design an installation that would fit, but the equipment and technology does exist. It's called a 'CT'. Stands for "Current Transformer". This is a transformer that step up or steps down Current. Not Voltage. We all experience Voltage Transformers because they are around us every day. The utility uses voltage transformer to step down the high voltage to the voltage (120/240v) usually to your house. Your door bell works off a voltage transformer, it takes the 120volts in the house circuit and steps it down to 12, 18 or sometimes 24 volts. But a CT steps CURRENT up or down and has almost no parasitic loss doing it.

Do you see where I am going with this. If a Ct could be installed around the large cable going to the battery, it could trigger a relay when the large cable reaches a current value of a specified threshold.

here is an example of what I am talking about but you would have to find one that had the right specifications. the large cable runs thru the center of this and the device senses the current in the cable.

I see two problems with this. 1. I still think it is cumbersome. 2. I don't know that it would react fast enough to avoid a catastrophic loss.

Hi Guest!

Hi Guest!

smilie in place of the real @

smilie in place of the real @

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

Pretty Please - add it to our Events forum(s) and add to the calendar! >>