eschneider

Jedi Warrior

Offline

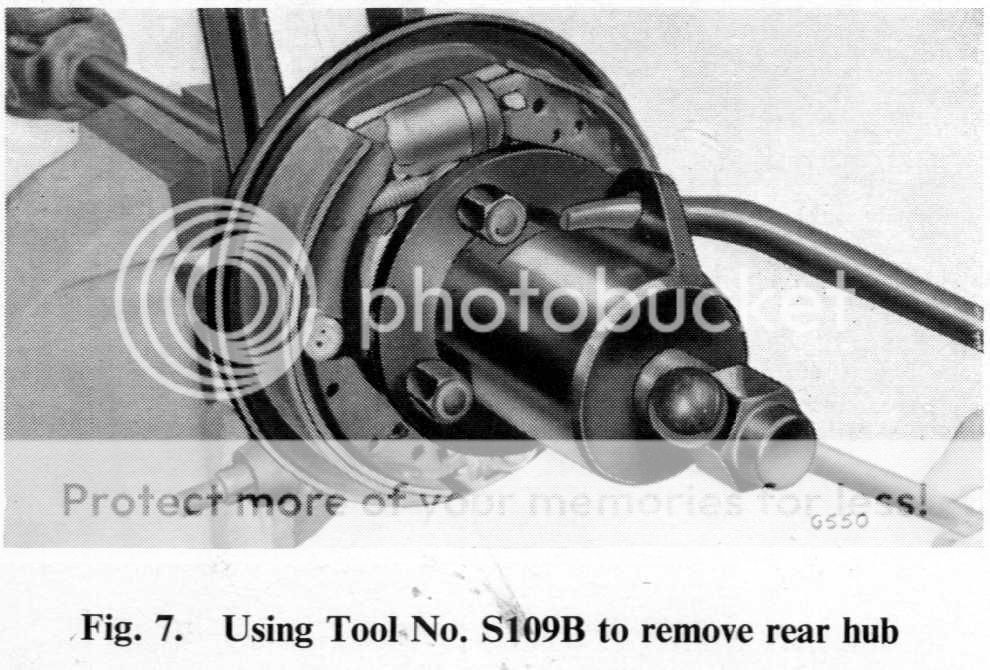

Doing rear wheel / hub seals on a MKIII spitfire, and the hub flange is really stuck on the axle. Taking a breather before breaking out the torch tomorrow.

So far have used a hub puller and BFH with some pentrating oil, an impact gun, and a MAPP torch.

I'm sure this is just an elbow-grease PITA, but thought I'd throw it out there in case someone had some words of wisdom or cautionary anecdotes.

So far have used a hub puller and BFH with some pentrating oil, an impact gun, and a MAPP torch.

I'm sure this is just an elbow-grease PITA, but thought I'd throw it out there in case someone had some words of wisdom or cautionary anecdotes.

Hi Guest!

Hi Guest!

smilie in place of the real @

smilie in place of the real @

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

,50/50 ATF and Acetone, and a little of this :hammer:, was what broke the drums loose on my 55 year old Ford tractor. It took a week of soaking and banging, but they finally broke loose. All I use anymore.

,50/50 ATF and Acetone, and a little of this :hammer:, was what broke the drums loose on my 55 year old Ford tractor. It took a week of soaking and banging, but they finally broke loose. All I use anymore.