HealeyPassion

Jedi Warrior

Offline

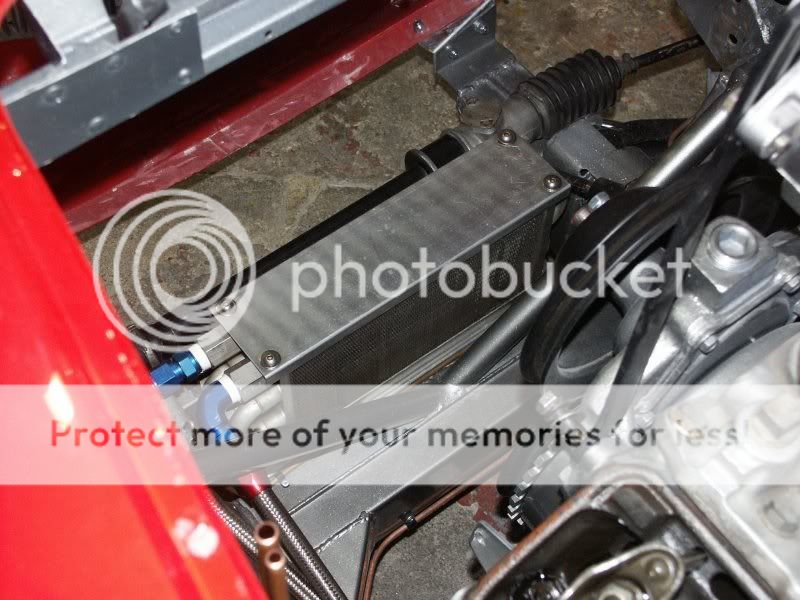

This undoubtedly has a limited audience, but for those interested and unstable like me :crazy: .... here is my project paper on AH works rally/Sebring oil cooler ducts.

AH Works Rally/Sebring Ducts

Cheers,

Steve

https://stevesaustinhealey.com

AH Works Rally/Sebring Ducts

Cheers,

Steve

https://stevesaustinhealey.com

Hi Guest!

Hi Guest!

smilie in place of the real @

smilie in place of the real @

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

Pretty Please - add it to our Events forum(s) and add to the calendar! >>