-

Hi Guest!

Hi Guest!

If you appreciate British Car Forum and our 25 years of supporting British car enthusiasts with technical and anicdotal information, collected from our thousands of great members, please support us with a low-cost subscription. You can become a supporting member for less than the dues of most car clubs.

There are some perks with a member upgrade!**Upgrade Now**

(PS: Subscribers don't see this gawd-aweful banner

Tips

- We have a special forum called "Member Articles" where you can submit actual articles for consideration for publication. Learn More

- Don't have an Avatar? If not, your avatar will default to the 1st character in your username. Go into "Account Details" to change your Avatar.

- Some basic forum navigation info: click

Hey - did you know if you click on the title of a thread it will take you to the first unread post since you last visited that thread?

- Hey Guest - Is your British Car Club in our Clubs database? If not, send me a PM - Basil

- Looking for a local club? Click the "Clubs" tab above and browse hundreds of clubs world-wide.

- Add Android or iPhone APP: click

- Did you know - any picture or video you add in your posts in any marque-specific forum will also get added to the Media Gallery automatically.

- A few more tips about posting and replying: click

- Hey there Guest - be sure to keep your profile page up to date with interesting info about yourself: learn more

- More tips and tricks on Posting and Replying: click

STOP!! Never post your email address in open forums. Bots can "harvest" your email! If you must share your email use a Private Message or use the

STOP!! Never post your email address in open forums. Bots can "harvest" your email! If you must share your email use a Private Message or use the  smilie in place of the real @

smilie in place of the real @

- Want to mention another member in a post & get their attention? WATCH THIS

- So, you created a "Group" here at BCF and would like to invite other members to join? Watch this!

- Hey Guest - A post a day keeps Basil from visiting you in the small hours and putting a bat up your nightdress!

- Hey Guest - do you know of an upcoming British car event?

Pretty Please - add it to our Events forum(s) and add to the calendar! >> Here's How <<

Pretty Please - add it to our Events forum(s) and add to the calendar! >> Here's How <<

- Hey Guest - you be stylin'

Change the look and feel of the forum to fit your taste. Check it out

- If you run across an inappropriate post, for example a post that breaks our rules or looks like it might be spam, you can report the post to the moderators: Learn More

- If you would like to try some different "looks" or styles for the site, scroll to the very bottom, on the left and click the Style Selector.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

TR6 Adding a PCV valve

- Thread starter steveg

- Start date

poolboy

Yoda

Offline

As long as the seal is good the cap isn't supposed to vent. I wouldn't be surprised if it did leak a bit though.

I have but never installed the Good Parts PCV kit. I think I must have bought it for the other engine that was in this car.

https://www.goodparts.com/product/pcv-kit/

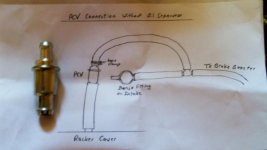

This is the sketch RG provided for it's installation.

I have but never installed the Good Parts PCV kit. I think I must have bought it for the other engine that was in this car.

https://www.goodparts.com/product/pcv-kit/

This is the sketch RG provided for it's installation.

Offline

Hello Steve & Poolboy, I really don't like that arrangement in the drawing. What I don't like is that the PCV is plumbed into the vac line to the brake booster. Even though the vac should be drawing everything to the manifold as we all experience oil goes everywhere. I can see over time that the oil would migrate to the brake booster. A brake booster vac line is a clean line its routing being from the intake stream to the booster. This provides the brake booster with maximum vacuum available and there is nothing else there to contaminate it. In providing a connection as in the drawing you are doing two things not normally present in a brake booster line or a PCV system. Firstly you are exposing the booster to possible contamination and secondly you are possibly reducing the amount of vacuum to the booster. That is because the given amount of vacuum available from the engine is now spread out through out the crankcase with its associated leaks. The vacuum will be compromised reducing its ability to operate the booster efficiently.

Of coarse in my mind I don't think it is a worthwhile effort to put a PCV system on a vintage engine. The only reason that a PCV system works on today's cars is because the technology of today compensates for the intrusion of waste gases into the cylinders. Things like variable cam timing, fuel injection and computer controlled engine operation allow such efficiency that the engine can still perform well with waste being dumped into the cylinder. Yes in the '70s engines ran with PCV systems without the new technology. But they did it poorly. We had poor driveability, engine surging and just talk to any professional mechanic to hear the complaints of what they had to go thru to keep the engines running reasonably well. Even to the point of modifying the carburettors and tune specs in defiance of the regulations. These old vintage engines are so inefficient in drawing in the intake charge that any intrusion of waste gases is just going to make things worse. Just note how many drivers of vintage engines will say "my engine runs best when it is a little rich". Of coarse it does. The intake passages are so in efficient that the cylinders need all the fuel they can get. Not more waste gas.

So that leads me to my solution. My solution is based on the premise that any environmental benifit from putting a PCV system on a vintage engine is so negligible that the benefit is inconsequential and a waist of time. There aren't that many vintage engines running around and their use is minimal. So my solution is to do truely what the term means, that is ventilate. Make it like the early engines were, vented to the atmosphere. Either a downpipe or a filter on the end of the crankcase opening. Attached is a picture of my Healey vent for the crankcase. This has the added benefit that the fumes no longer choke up the rear carb which is where the hose originally went. The rear carb is as clean as the front one. That K&N filter doesn't even weep oil and believe it or not my rear main seal doesn't wet the floor. So the answer is Just Vent it, Don't Plumb it.

Of coarse in my mind I don't think it is a worthwhile effort to put a PCV system on a vintage engine. The only reason that a PCV system works on today's cars is because the technology of today compensates for the intrusion of waste gases into the cylinders. Things like variable cam timing, fuel injection and computer controlled engine operation allow such efficiency that the engine can still perform well with waste being dumped into the cylinder. Yes in the '70s engines ran with PCV systems without the new technology. But they did it poorly. We had poor driveability, engine surging and just talk to any professional mechanic to hear the complaints of what they had to go thru to keep the engines running reasonably well. Even to the point of modifying the carburettors and tune specs in defiance of the regulations. These old vintage engines are so inefficient in drawing in the intake charge that any intrusion of waste gases is just going to make things worse. Just note how many drivers of vintage engines will say "my engine runs best when it is a little rich". Of coarse it does. The intake passages are so in efficient that the cylinders need all the fuel they can get. Not more waste gas.

So that leads me to my solution. My solution is based on the premise that any environmental benifit from putting a PCV system on a vintage engine is so negligible that the benefit is inconsequential and a waist of time. There aren't that many vintage engines running around and their use is minimal. So my solution is to do truely what the term means, that is ventilate. Make it like the early engines were, vented to the atmosphere. Either a downpipe or a filter on the end of the crankcase opening. Attached is a picture of my Healey vent for the crankcase. This has the added benefit that the fumes no longer choke up the rear carb which is where the hose originally went. The rear carb is as clean as the front one. That K&N filter doesn't even weep oil and believe it or not my rear main seal doesn't wet the floor. So the answer is Just Vent it, Don't Plumb it.

Attachments

Offline

I have the Moss finned valve cover; the cap has a 1/16" vent hole. The stock cap would need a vent.

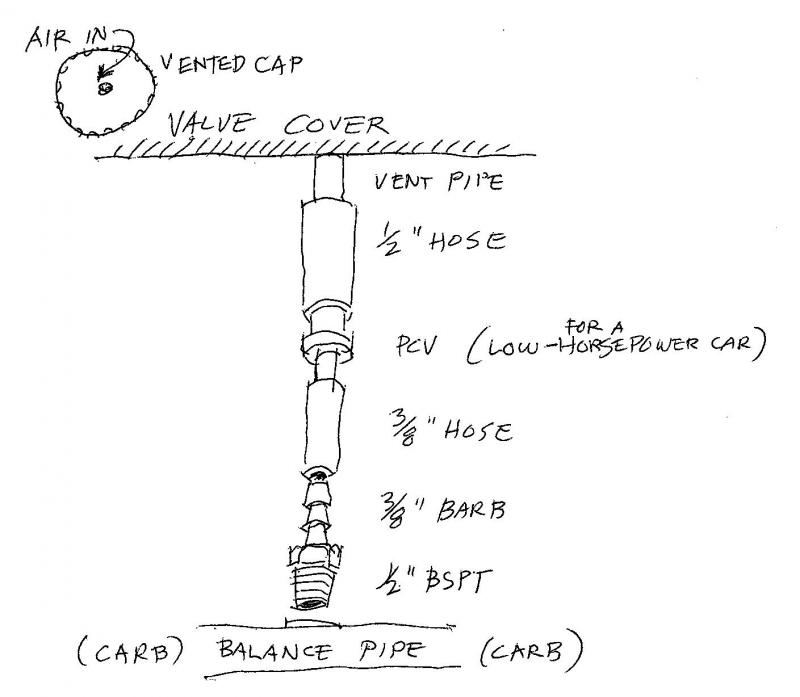

The Good Parts drawing is functionally the same as this:

EDIT: Vette - with respect, there is much information online detailing the engine-benefits a PCV has in vintage, hotrod, custom setups.

For example:

http://www.hastingsfilter.com/Literature/TSB/94-2R1.pdf

http://mewagner.com/

The Good Parts drawing is functionally the same as this:

EDIT: Vette - with respect, there is much information online detailing the engine-benefits a PCV has in vintage, hotrod, custom setups.

For example:

http://www.hastingsfilter.com/Literature/TSB/94-2R1.pdf

http://mewagner.com/

carpecursusII

Jedi Trainee

Offline

You do not want a vented cap to be used with a PCV system, it will draw a ton of air and over lean the mixture, not to mention burn excessive oil.