M

Member 10617

Guest

Guest

Offline

This posting picks up on an earlier thread....

I see that Moss is selling new non-generic vacuum advance units.

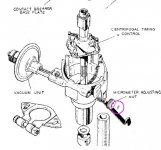

I am thinking of replacing my old one with a new one, but I don't know the procedure.

Can someone out there give me some directions on how to remove the old unit and install the new unit (or direct me to some posted instructions). It looks straightforward enough, but appearances are always deceptive!

I see that Moss is selling new non-generic vacuum advance units.

I am thinking of replacing my old one with a new one, but I don't know the procedure.

Can someone out there give me some directions on how to remove the old unit and install the new unit (or direct me to some posted instructions). It looks straightforward enough, but appearances are always deceptive!

Hey there Guest!

Hey there Guest!

smilie in place of the real @

smilie in place of the real @

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

A friendly reminder - be careful what links you click on here. If a link is posted by someone you don't know, or the URL looks fishy, DON'T CLICK. Spammers sometimes post links that lead to sites that can infect your computer, so be mindful what you click.

A friendly reminder - be careful what links you click on here. If a link is posted by someone you don't know, or the URL looks fishy, DON'T CLICK. Spammers sometimes post links that lead to sites that can infect your computer, so be mindful what you click.