mgedit

Jedi Knight

Offline

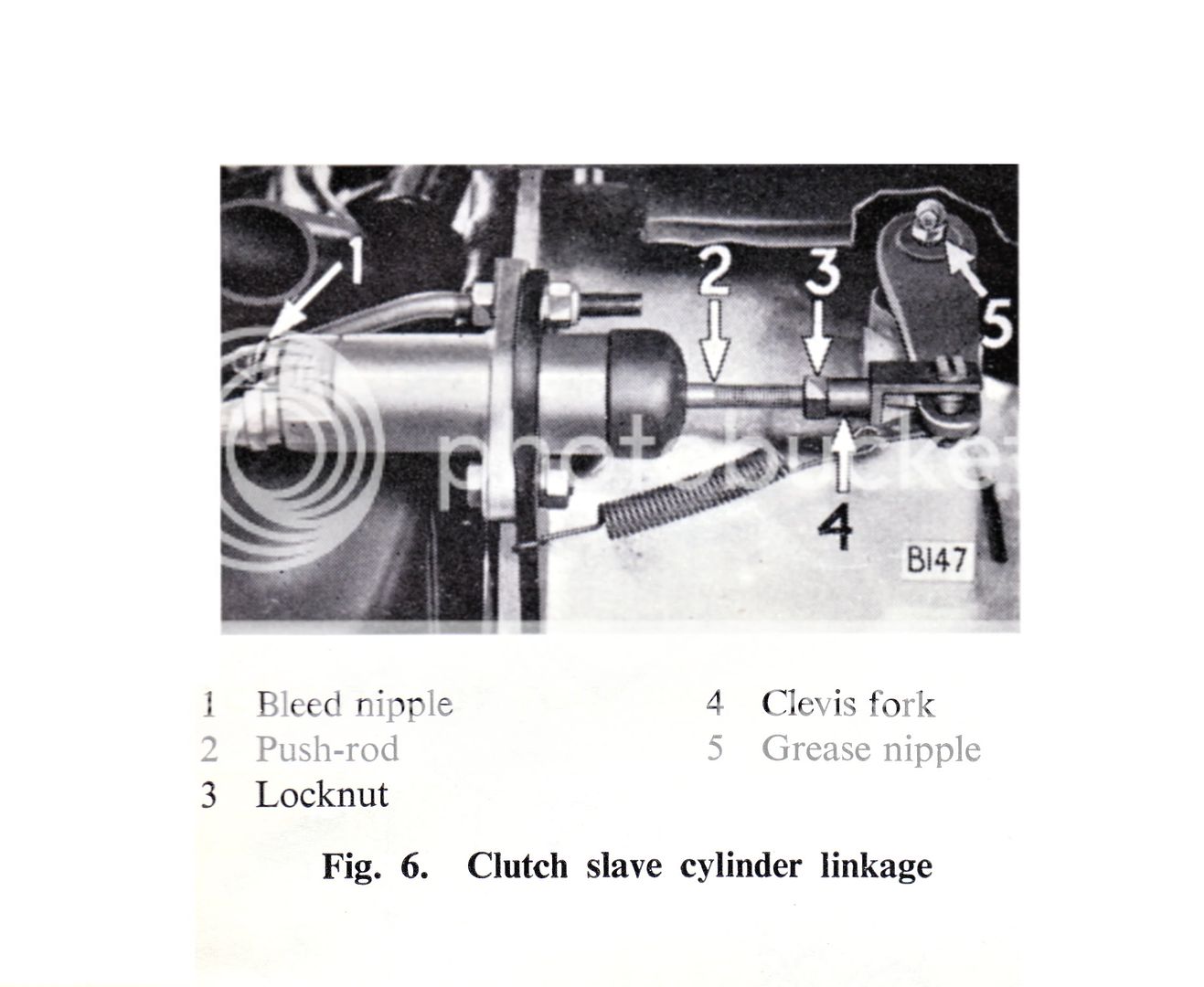

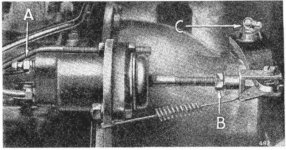

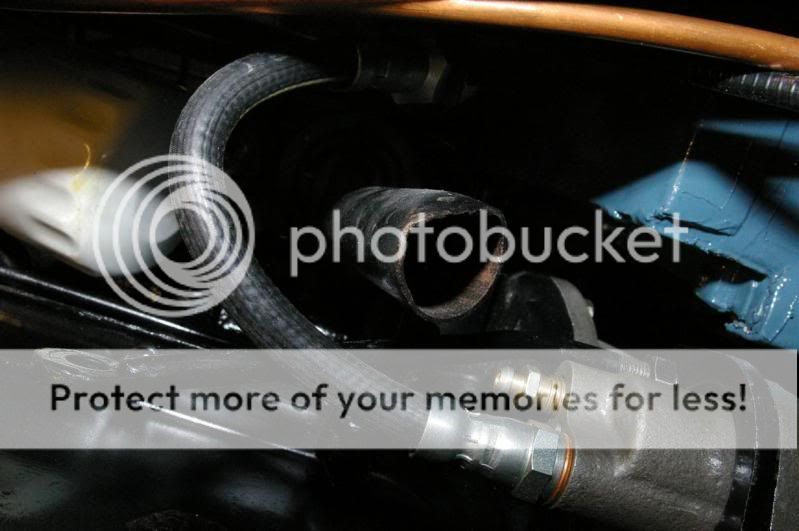

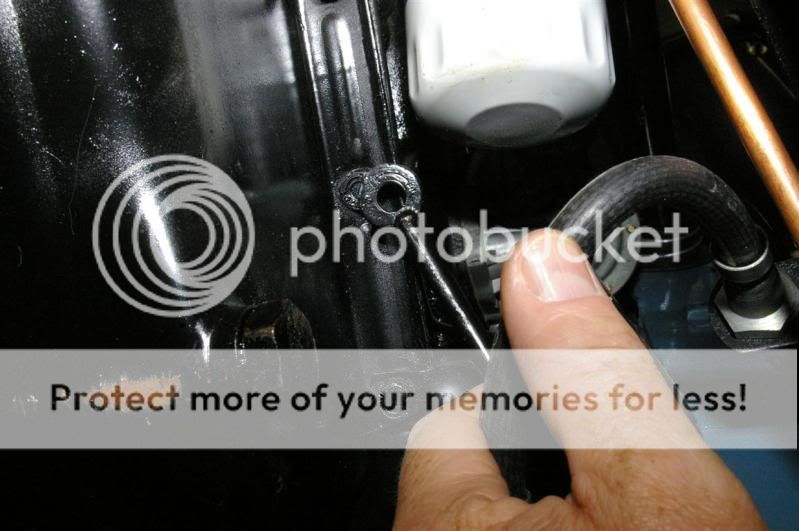

Just fitting the slave for the clutch. Looks like support bracket attaches to one of the oil pan bolts. Assume that is correct? Also does the fork go into the centre of the three holes in the clutch shaft "arm"? Why are the other two holes there? Do they have something to do with later adjustments? I have a new spring ordered as the one I have seems a bit overstretched.

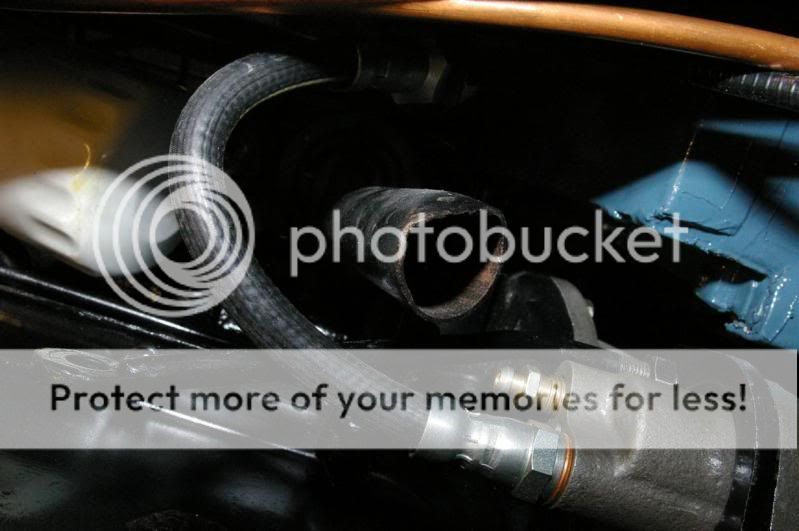

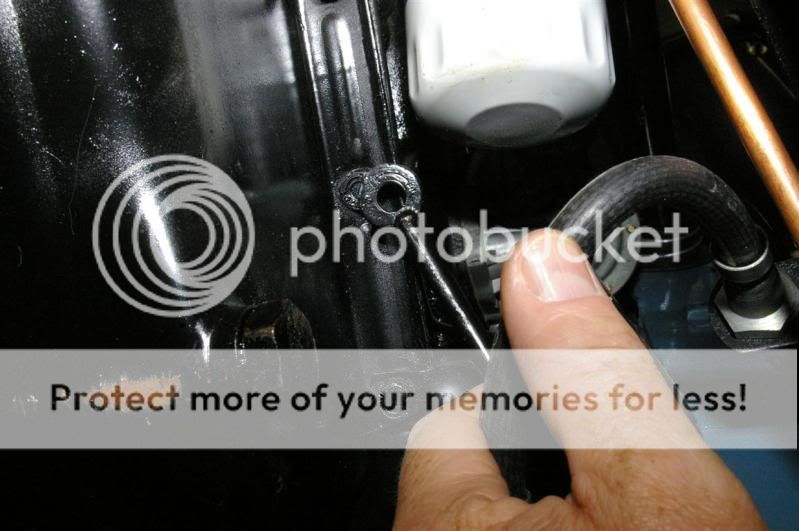

Here is how I have it test fitted now. Does this all seem correct? Cheers, Mike

Here is how I have it test fitted now. Does this all seem correct? Cheers, Mike

Hi Guest!

Hi Guest!

smilie in place of the real @

smilie in place of the real @

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

Pretty Please - add it to our Events forum(s) and add to the calendar! >>