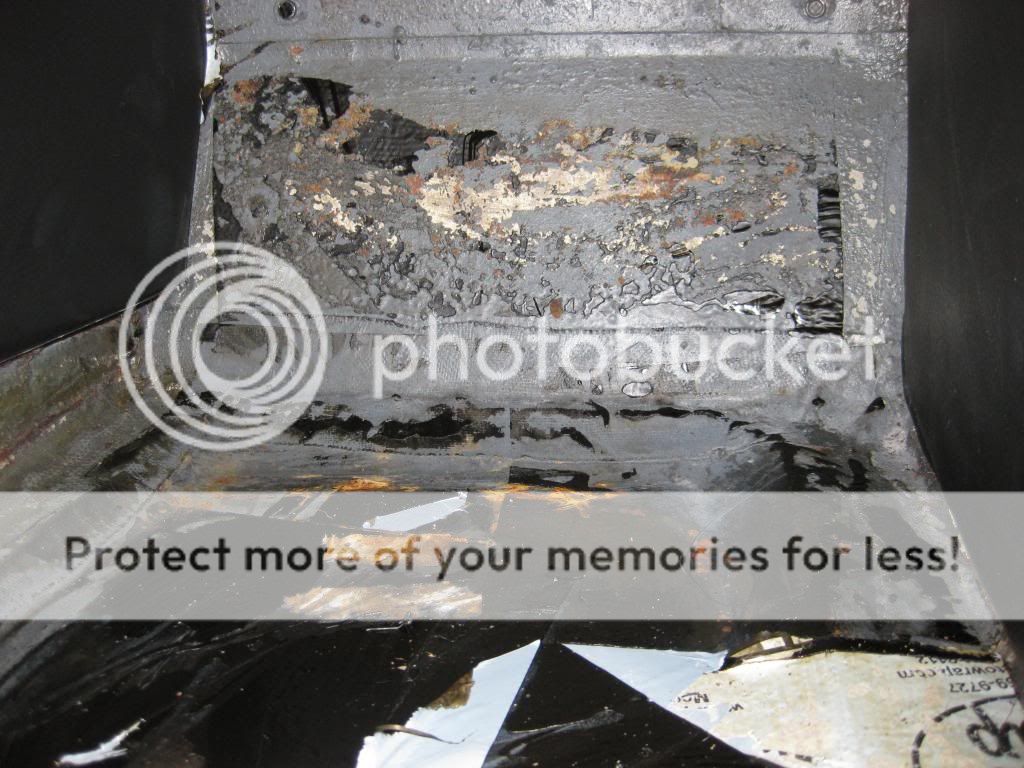

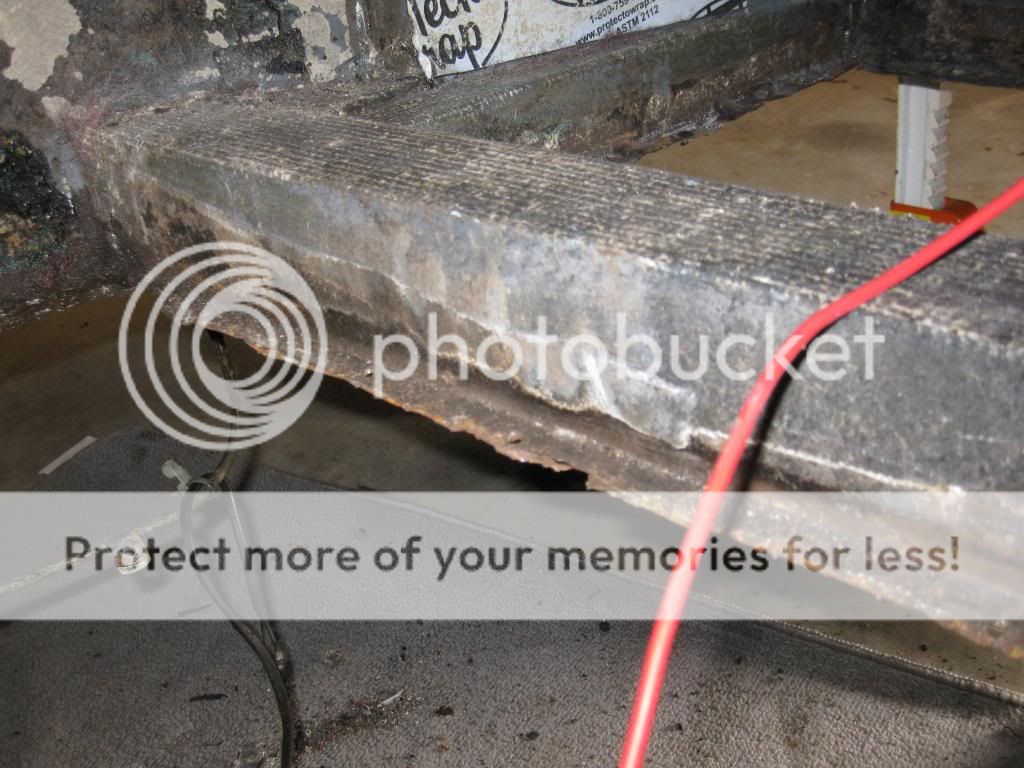

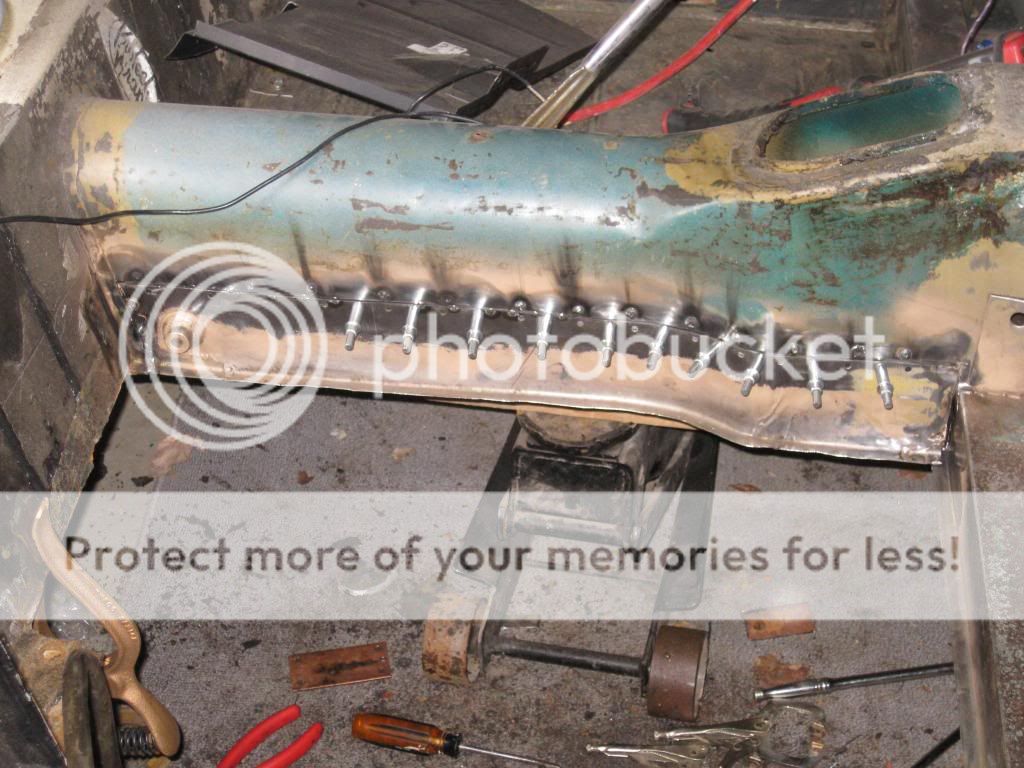

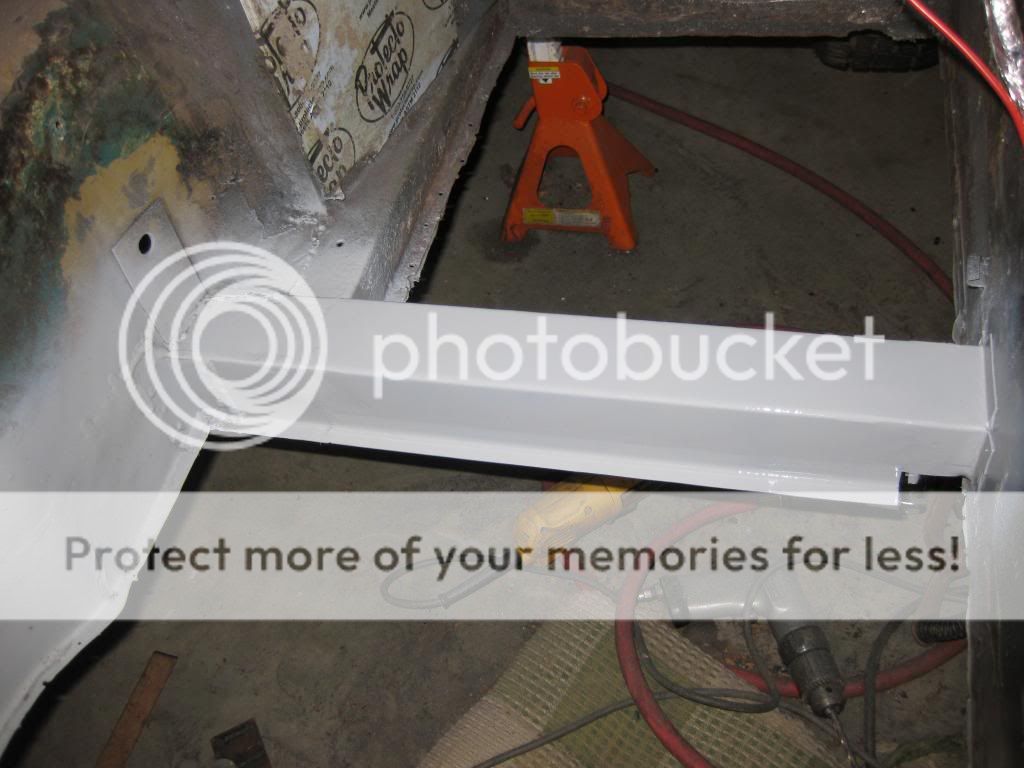

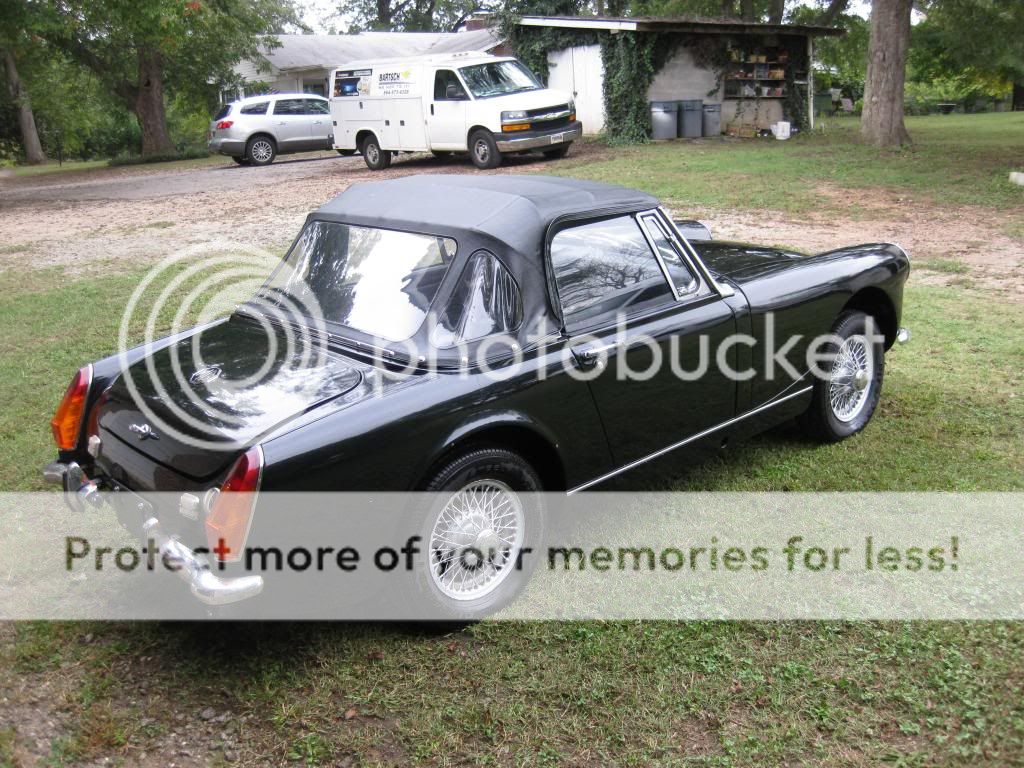

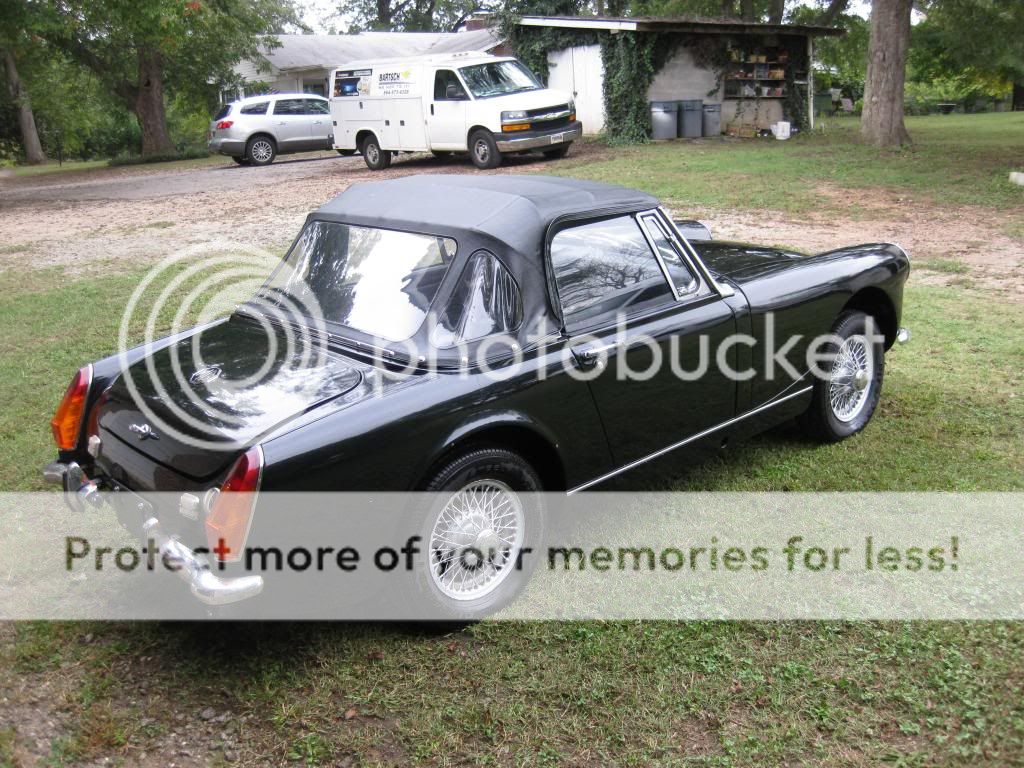

So i had another build log on this forum. it was a 1963 midget that i was going to put a ford duratec into. fully custom front suspension, all the bells and whistles. that was a bit over my head, in retrospect i was thinking too big. I was definitely not keeping things simple. i had a moment of sanity. i knew i wanted to have an spridget, I knew i wanted to do an engine swap. so i did a bit of research on what would probably be the easiest swap i could do. I came up with the toyota 4age engine. they are compact, lightweight, make good power. there are version from 135hp all the way up to 165hp engines. I narrowed my selection down to the 16v 4age found in a Toyota GTS corolla. It comes standard set up for RWD, fuel injected, and makes about 135 crank hp. The 20v version is found in the Japanese market, those are the ones that make the highest hp stock. but they are not set up for RWD standard, and are much more expensive. I picked up my 16v locally for $475, and have since sold off some parts i didn't need for $150 so far. The 20v 4age can be found on ebay and importers, expect to pay anywhere from $1000-$1600 from what i have seen. I figured the money i save on the engine i could add a bit of power with a set of cams ect. So thats the engine figured out. now for the car. I saw an add a state over from me for a black RWA MG Midget with a blown engine. the pictures of the car looked great. i thought i found my car. I chose to go ahead and negotiate a price for the car all ready because it was over 4 hours away. i only wanted to go see it once and i wanted to pick it up at that time also. this was a bad idea. After negotiating a price for the car sight unseen i drove down with a U-haul trailer to pick it up. when i saw it i could tell it wasn't what the pictures represented. the paint job was self done, or at least done by an amateur. only the exterior was repainted, it was def not taken down to the bare tub and prepped properly. lots of orange peel, and even worse, i saw rust starting to pop out from the door pillars and a few places in the rockers. i also pulled up the carpet but i couldn't see the actual floors because there was tar backed sound deadening everywhere, It seemed solid though. So i was in a predicament, i drove all this way and with a trailer. I know i should have walked away but i renegotiated with the owner for less money after telling him about my issues with the car. so here is the car after i washed it a bit.

Hi Guest!

Hi Guest!

smilie in place of the real @

smilie in place of the real @

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

Pretty Please - add it to our Events forum(s) and add to the calendar! >>