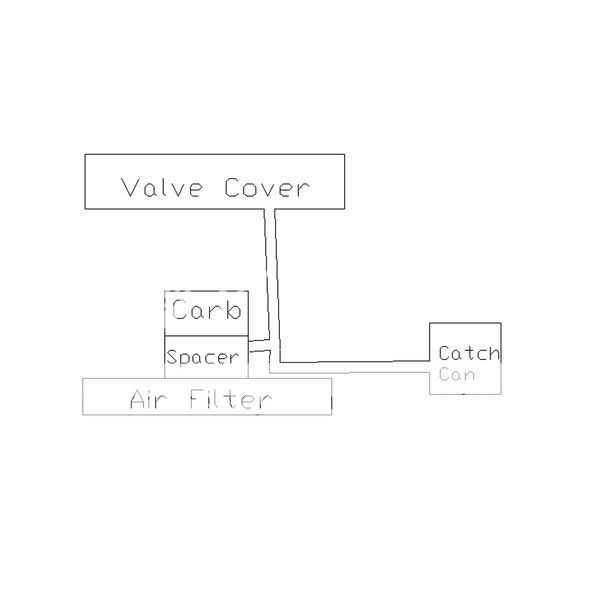

Yeah, I was going to play around with different orfices in the hose from the valve cover to the carb, but the regular hose (with no restricting orfice) worked out fine for me. With the engine running, my engine generates a moderate amount of pressure at the valve-cover "exhaust"....but no real smoke. Maybe just a bit of oil fumes. My engine is rebuilt on a regular basis, but it is also run much harder than most 1500s.

One thought: be sure the hose comes out of the valve cover and goes "up" as high as possible (against the bonnet). This may keep liquid oil from migrating to the carb (because it will have to go uphill).

Whatever you do, you need to have a slight suction to the valve cover so that the crankcase is under a slight vacuum, but somehow keep from sucking oil.

It's interesting to note that you are pushing a bit of oil from the dipstick. That's pretty common. Probably because the engine is pretty long stoke. Mine was doing that a little when I autocrossed it, but it became much worse when I began racing regularly. Eventually, I threaded the dipstick hole. Now, I run the car with a bolt threaded (and safety wired) into the dipstick hole. I remove the bolt (and use the normal dipstick) when I need to check the oil.

I enjoy working on my car, but frankly, I think the Triumph/BL 1500 engine is one of the crappiest engines ever put in a sports car.

The upside is that it keeps me busy and out of trouble. /ubbthreads/images/graemlins/tongue.gif

Hi Guest!

Hi Guest!

smilie in place of the real @

smilie in place of the real @

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

Pretty Please - add it to our Events forum(s) and add to the calendar! >>