-

Hi Guest!

Hi Guest!

If you appreciate British Car Forum and our 25 years of supporting British car enthusiasts with technical and anicdotal information, collected from our thousands of great members, please support us with a low-cost subscription. You can become a supporting member for less than the dues of most car clubs.

There are some perks with a member upgrade!**Upgrade Now**

(PS: Subscribers don't see this gawd-aweful banner

Tips

- We have a special forum called "Member Articles" where you can submit actual articles for consideration for publication. Learn More

- Don't have an Avatar? If not, your avatar will default to the 1st character in your username. Go into "Account Details" to change your Avatar.

- Some basic forum navigation info: click

Hey - did you know if you click on the title of a thread it will take you to the first unread post since you last visited that thread?

- Hey Guest - Is your British Car Club in our Clubs database? If not, send me a PM - Basil

- Looking for a local club? Click the "Clubs" tab above and browse hundreds of clubs world-wide.

- Add Android or iPhone APP: click

- Did you know - any picture or video you add in your posts in any marque-specific forum will also get added to the Media Gallery automatically.

- A few more tips about posting and replying: click

- Hey there Guest - be sure to keep your profile page up to date with interesting info about yourself: learn more

- More tips and tricks on Posting and Replying: click

STOP!! Never post your email address in open forums. Bots can "harvest" your email! If you must share your email use a Private Message or use the

STOP!! Never post your email address in open forums. Bots can "harvest" your email! If you must share your email use a Private Message or use the  smilie in place of the real @

smilie in place of the real @

- Want to mention another member in a post & get their attention? WATCH THIS

- So, you created a "Group" here at BCF and would like to invite other members to join? Watch this!

- Hey Guest - A post a day keeps Basil from visiting you in the small hours and putting a bat up your nightdress!

- Hey Guest - do you know of an upcoming British car event?

Pretty Please - add it to our Events forum(s) and add to the calendar! >> Here's How <<

Pretty Please - add it to our Events forum(s) and add to the calendar! >> Here's How <<

- Hey Guest - you be stylin'

Change the look and feel of the forum to fit your taste. Check it out

- If you run across an inappropriate post, for example a post that breaks our rules or looks like it might be spam, you can report the post to the moderators: Learn More

- If you would like to try some different "looks" or styles for the site, scroll to the very bottom, on the left and click the Style Selector.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

T-Series Puff of blue smoke on startup

- Thread starter PAUL161

- Start date

Offline

Tom, I hope that's correct, to my knowledge the seals are the original O ring type, no mention that the seals were of another type when the engine was rebuilt. I'll put some oil in the stem washers and see how long it takes for the oil to leak down past the collets. I'm not worried about the situation, so no big rush to solve the problem during the driving season, I'll wait until she's put to bed for the winter and replace them. Thanks for your comment. PJ

Offline

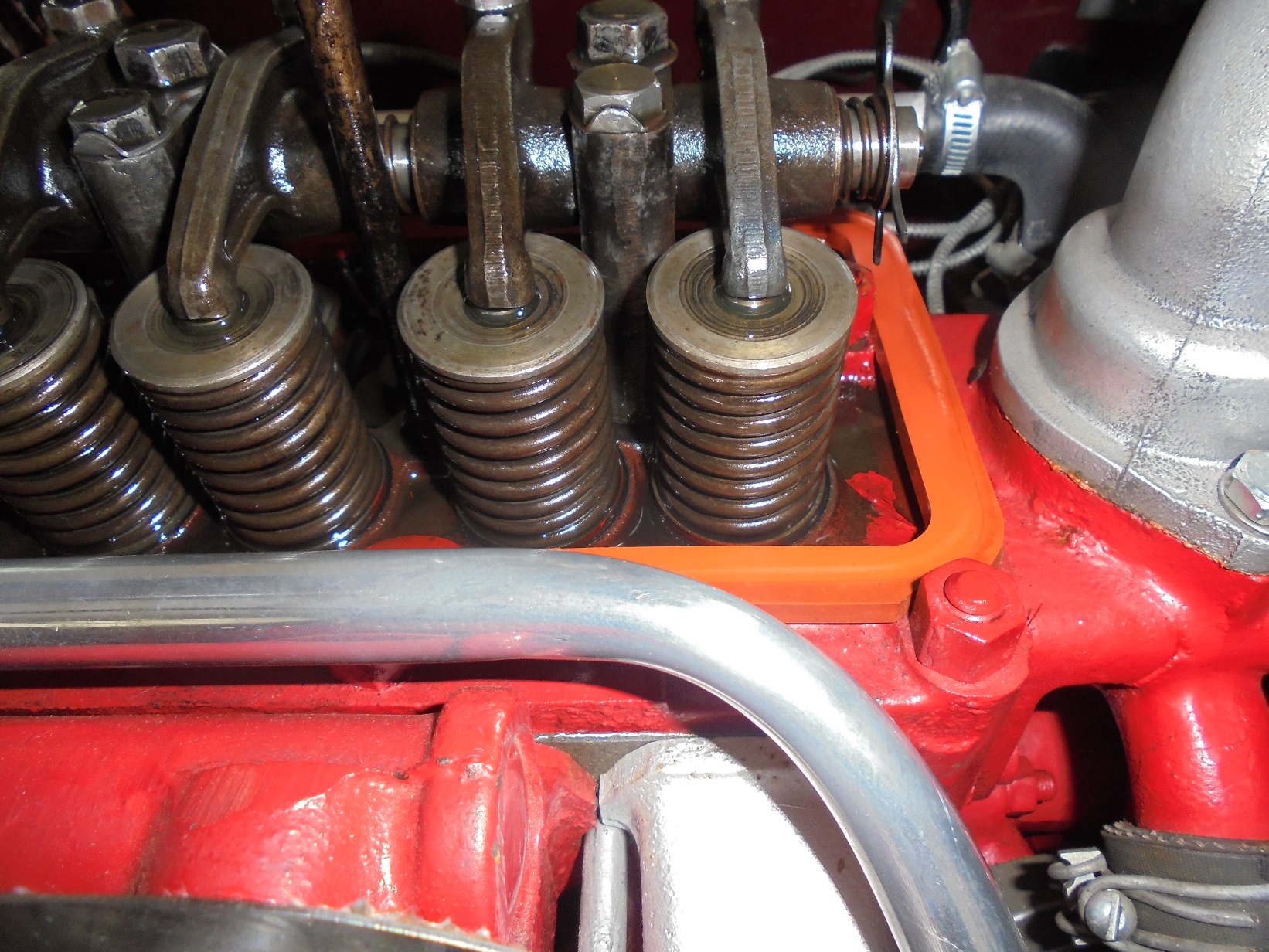

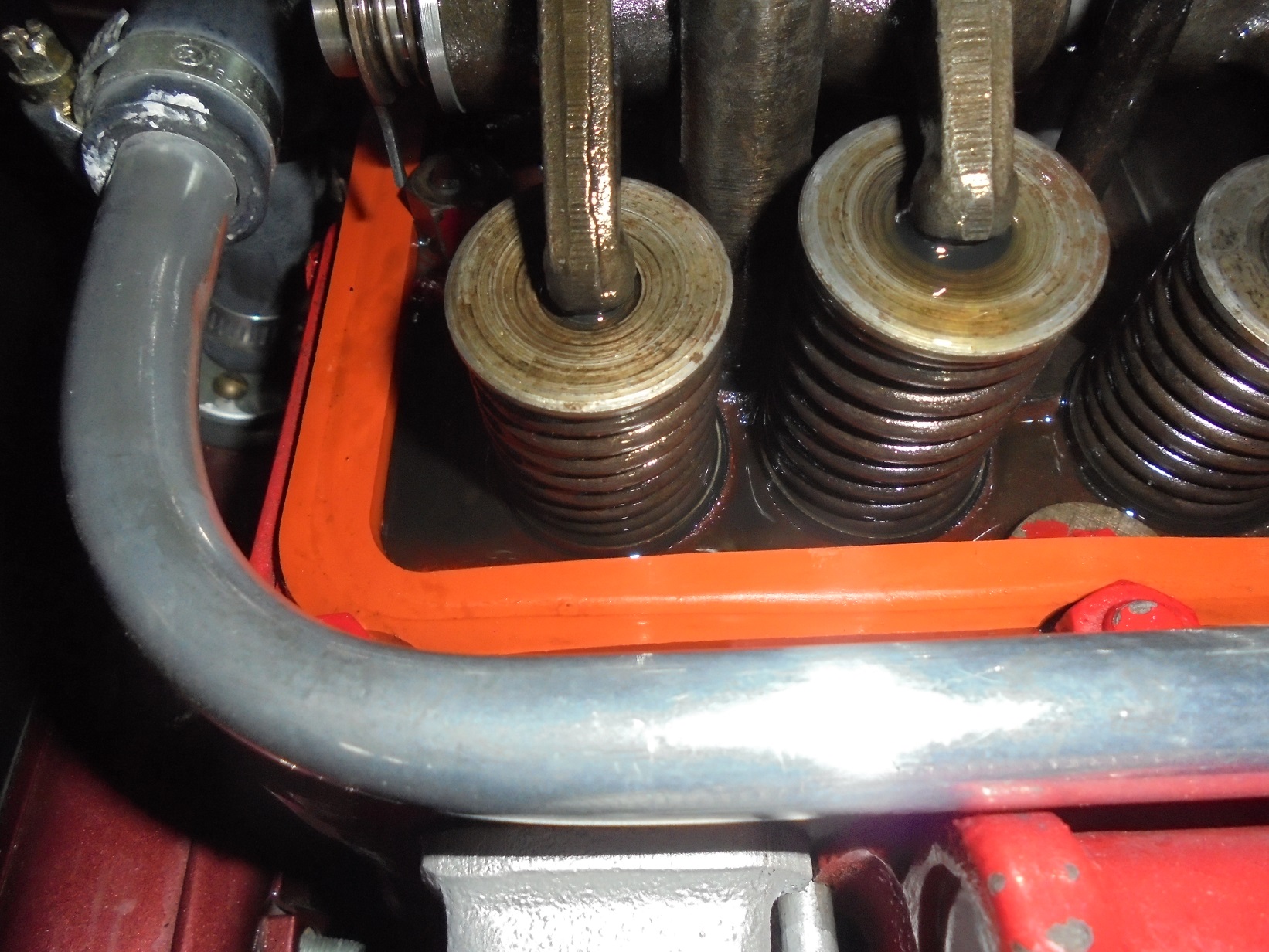

Last night I checked the valve seals for leakage. Found the 1-2-& 3 will leak down overnight to minimum oil in the upper washer, and number 8 will leak down to zero in 2 hours. 4-5-6 & 7 don't leak down at all. Naturally, I'll replace all the seals. I'll order 2 sets in case one gets damaged during installation. Here's a picture of 1-2-and 3 in the morning the second picture is number 8 after 1 hour. The rest still have oil in the washers after 3 days of setting. Number 8 is the prime culprit for the smoke after start-up after a short time! PJ

Offline

Exhaust and intake use the same O rings. I'm one to stick with what the factory installed. Not saying other options aren't as good, but why change after all these years. I don't experiment with a 65-year-old engine. Only a guess, but I would venture a guess that 95% of these engines have the original design seals, quite a testament to the factory's original design!

Offline

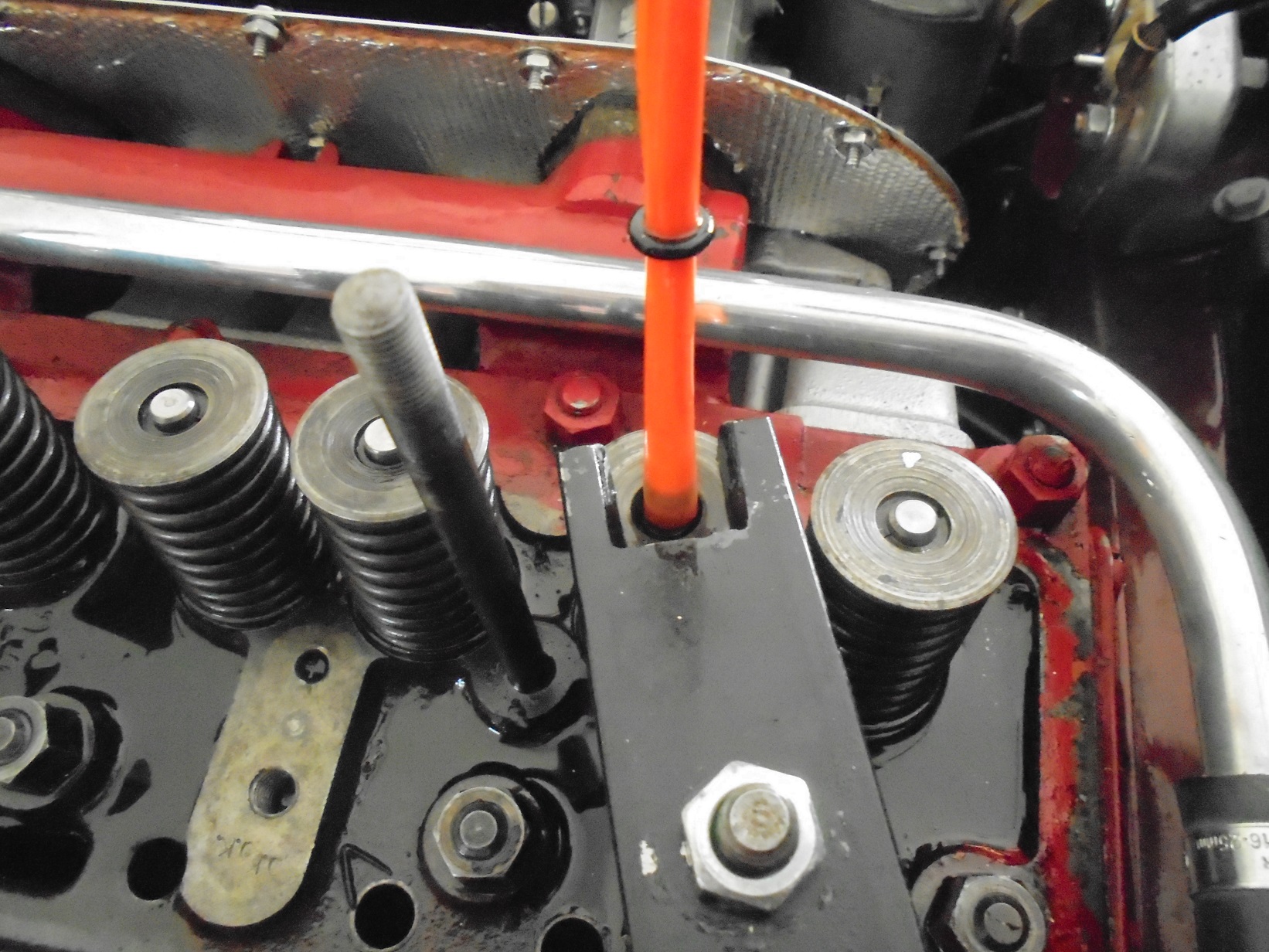

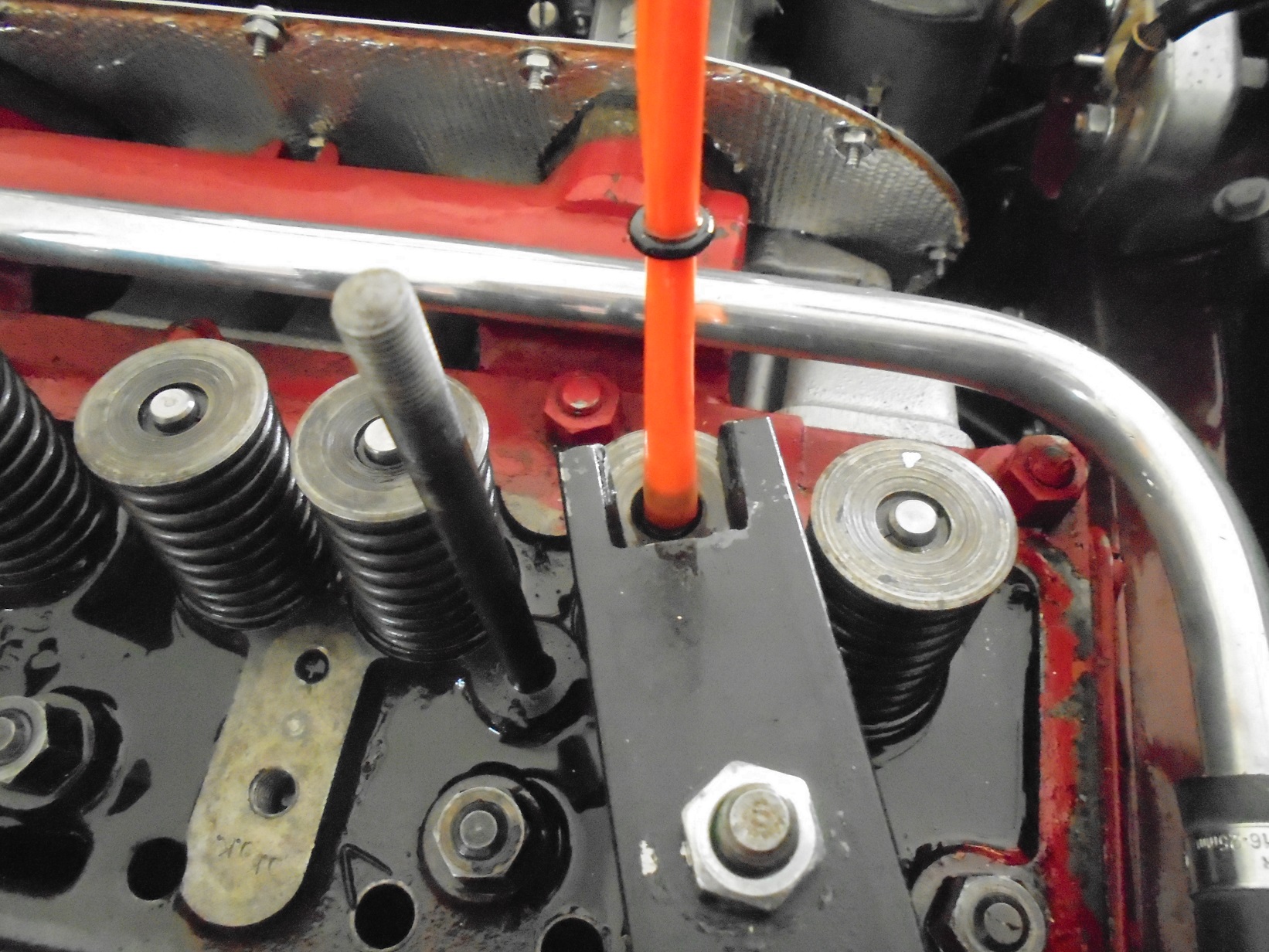

So instead of paying $100 for a tool and not being sure it would work, I made my own for free!!

So instead of paying $100 for a tool and not being sure it would work, I made my own for free!! PJ

PJXJtom

Member

Offline

looks good, did something similar about 45 years ago and still have it, welded a 1/2" round bar on it to leaver, needed a multi fit for various size motors....are you air compressing the cylinders? ... still might be worth considering the valve stem caps if you have the problem again sooner than expected.

XJtom

Member

Offline

bush mechanics make the world crank over, i have a free library you might find something of interest there>>> www.jaguar-wiring-schematics.info

Offline

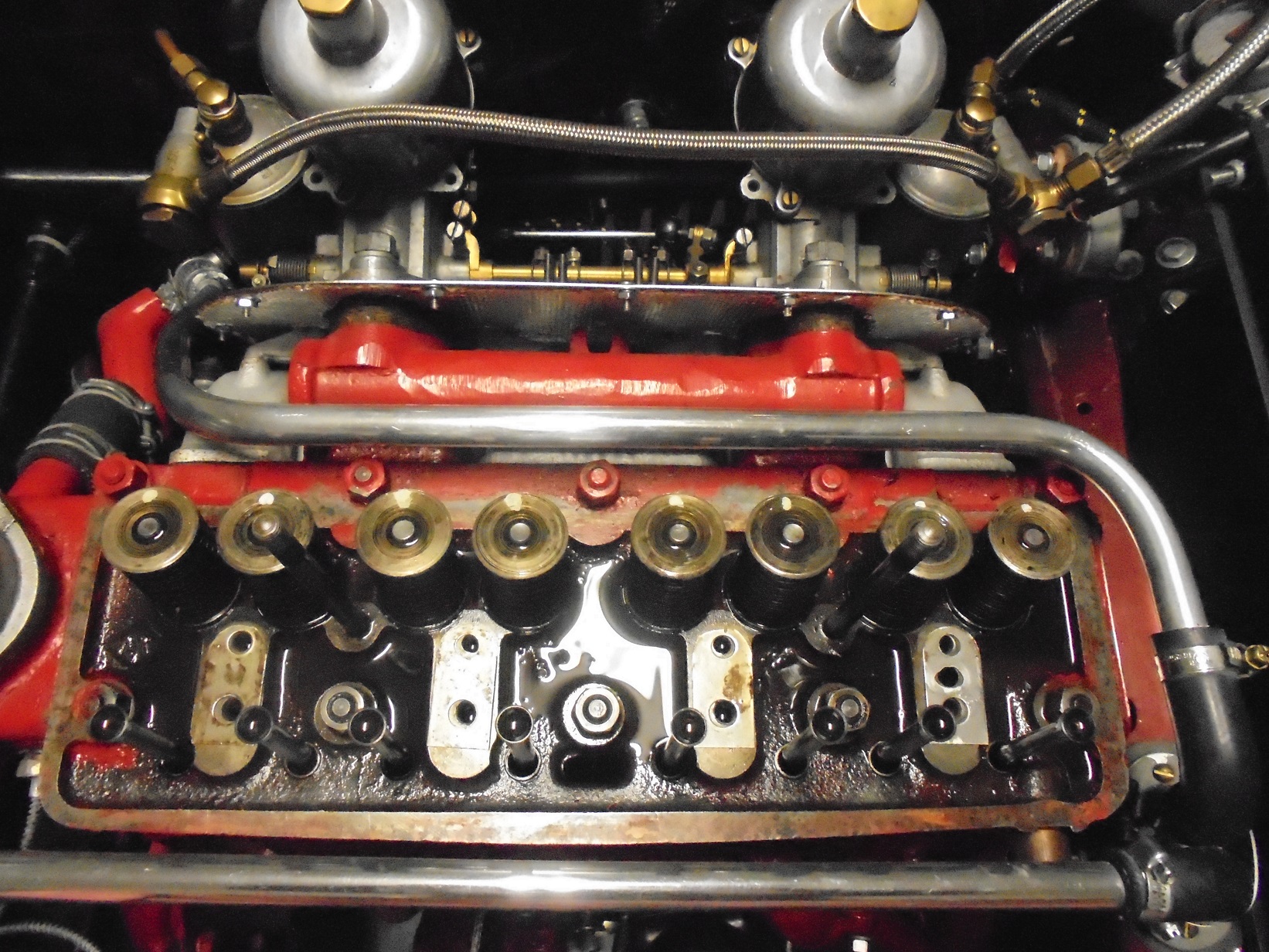

Two cylinders are done. I used the larger split soda straw method to get the seals over the valve stems with a generous amount of oil on the straw and stem, it works very well, and no seal damage! The collets are a little pain, but not much. Two cylinders are done as of this post. PJ

Offline

After 24 hours, zero oil leak down.  Two of the washers were stuck, so I had to raise the cylinder pressure to 100 lbs, did a little tapping with a very small brass hammer and they popped loose. Very easy job. The rocker tower shims shown are .020 to give a better profile for the rocker riding on the valve stem with the Crane cam. PJ

Two of the washers were stuck, so I had to raise the cylinder pressure to 100 lbs, did a little tapping with a very small brass hammer and they popped loose. Very easy job. The rocker tower shims shown are .020 to give a better profile for the rocker riding on the valve stem with the Crane cam. PJ

Last edited:

Offline

Also, through a friend in Tasmania, I found out that the O rings I removed were not the correct O rings for my engine! They are square-edged

and not round as required! They will work for a short time but will eventually leak! New ones from Moss, as on the soda straw being installed are correct. PJ

and not round as required! They will work for a short time but will eventually leak! New ones from Moss, as on the soda straw being installed are correct. PJ