-

Hi Guest!

Hi Guest!

You can help ensure that British Car Forum (BCF) continues to provide a great place to engage in the British car hobby! If you find BCF a beneficial community, please consider supporting our efforts with a subscription.

There are some perks with a member upgrade!**Upgrade Now**

(PS: Subscribers don't see this gawd-aweful banner

Tips

- We have a special forum called "Member Articles" where you can submit actual articles for consideration for publication. Learn More

- Don't have an Avatar? If not, your avatar will default to the 1st character in your username. Go into "Account Details" to change your Avatar.

- Some basic forum navigation info: click

Hey - did you know if you click on the title of a thread it will take you to the first unread post since you last visited that thread?

- Hey Guest - Is your British Car Club in our Clubs database? If not, send me a PM - Basil

- Looking for a local club? Click the "Clubs" tab above and browse hundreds of clubs world-wide.

- Add Android or iPhone APP: click

- Did you know - any picture or video you add in your posts in any marque-specific forum will also get added to the Media Gallery automatically.

- A few more tips about posting and replying: click

- Hey there Guest - be sure to keep your profile page up to date with interesting info about yourself: learn more

- More tips and tricks on Posting and Replying: click

STOP!! Never post your email address in open forums. Bots can "harvest" your email! If you must share your email use a Private Message or use the

STOP!! Never post your email address in open forums. Bots can "harvest" your email! If you must share your email use a Private Message or use the  smilie in place of the real @

smilie in place of the real @

- Want to mention another member in a post & get their attention? WATCH THIS

- So, you created a "Group" here at BCF and would like to invite other members to join? Watch this!

- Hey Guest - A post a day keeps Basil from visiting you in the small hours and putting a bat up your nightdress!

- Hey Guest - do you know of an upcoming British car event?

Pretty Please - add it to our Events forum(s) and add to the calendar! >> Here's How <<

Pretty Please - add it to our Events forum(s) and add to the calendar! >> Here's How <<

- Hey Guest - you be stylin'

Change the look and feel of the forum to fit your taste. Check it out

- If you run across an inappropriate post, for example a post that breaks our rules or looks like it might be spam, you can report the post to the moderators: Learn More

- If you would like to try some different "looks" or styles for the site, scroll to the very bottom, on the left and click the Style Selector.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

MGB 1978 MGB clutch is out..!

- Thread starter Guywith2Mgs

- Start date

Online

Is the master cylinder piston moving when you push the pedal? Seems like you need to replace both master and slave.

Bob

Bob

Offline

Well, as I posted back in #2, replacing M/C, slave and flex line at one go will eliminate any issues. And as Grantura mentions later, keep the old ones and have them re-sleeved if you intend to keep the car.

All a pain in the butt, but a guarantee the issue is resolved.

All a pain in the butt, but a guarantee the issue is resolved.

Online

When you put it back, do yourself a favor and bench bleed the new master. Just cover the outlet with a finger and work the piston until fluid squirts out. And when doing the replacement be sure to water wash all fluid spills off the paint immediately.

Bob

Bob

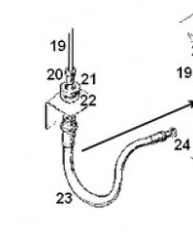

New master cylinder is back in. Also replaced the flex line - but have a leak trying to connect the flex line to the hard line. Very difficult to see or find a good fitting tool to back off or tighten the tube nut (20 below ) or the lock nut below it (21). Probably lots of air in the system now. The good news I could see a bit of movement in the slave piston. Down this rabbit hole again! After looking at the hard line - looks like it may not be too tough running a new one from master to slave.

Offline

Save some grief and get a couple line wrenches. SAE, 7/16" amd 1/2". A well stocked NAPA store will have individual ones. Likely better quality than these but if you intend to keep the MG it will come in handy. Likely you need not replace the steel line.

www.harborfreight.com

www.harborfreight.com

EDIT: The flex line may be 5/8" at the fittings, I don't recall.

Double-End Metric Flare Nut Wrench Set, 5 Piece

Amazing deals on this 5Pc Metric Double-End Flare Nut Wrench Set at Harbor Freight. Quality tools & low prices.

EDIT: The flex line may be 5/8" at the fittings, I don't recall.

Last edited:

Save some grief and get a couple line wrenches. SAE, 7/16" amd 1/2". A well stocked NAPA store will have individual ones. Likely better quality than these but if you intend to keep the MG it will come in handy. Likely you need not replace the steel line.

Double-End Metric Flare Nut Wrench Set, 5 Piece

Amazing deals on this 5Pc Metric Double-End Flare Nut Wrench Set at Harbor Freight. Quality tools & low prices.www.harborfreight.com

EDIT: The flex line may be 5/8" at the fittings, I don't recall.

Offline

If it is what I think it is, it is to hold it on the bracketThanks Doc! Any idea what the lock nut is below the tube nut? Things broke loose after tons of blaster. But I could feel the line and mechanism turn a bit above the flex hose while trying to break everything loose with a vice grip. Ugh!!!

Offline

Well, the way it was designed to work is the bracket on the frame holds the end of the flex line via that nut from the "top side" so you can tighten the steel line's ferrule to it. If the bracket and/or the line fitting have been rounded and buggered, Vice Grips to remove and replacement ferrule may be the only option.

Hello All,

Looking for any new help with my 77 MGB clutch problem. Replaced both master and slave and flex hose. It appears most air has been bled out successfully. The slave piston only travels maybe a 1/4". Just watched a video from moss on evacuating air out of the slave. Will try that next

Questions - What is the actual travel distance for the clutch piston?

Thanks!

Looking for any new help with my 77 MGB clutch problem. Replaced both master and slave and flex hose. It appears most air has been bled out successfully. The slave piston only travels maybe a 1/4". Just watched a video from moss on evacuating air out of the slave. Will try that next

Questions - What is the actual travel distance for the clutch piston?

Thanks!

Offline

has it worked? The reason I ask is that it took me almost an entire summer to sort my clutch a few years ago - NOTE it is a different line!!! - But what I finally realized is that my new clutch line wasn't seating properly hence the ongoing air issues. It wasn't seating properly because it was made of chinesium. I finally found a hose (again the Midget line is a plastic) and reused the original ends - finally fixed it. I find that there continue to be massive issues with a lot of the new parts being speced to the lowest bidder.Follow up: lots of air came out trying this method like the whole system is full of air.

Offline

love it when a plan (finally) comes togetherGood news bled like back in the day; open, pedal down, close, pedal up…repeat. Just had to top off the master cylinder about every 1 or 2 bleeds, it holds soooo little fluid.

Thanks for the help!!!