I'm ready to install the down pipes on my BT7,I have some copper gaskets which seem to be very thin, .016 thick is this good? The other gaskets I have are thicker and are made of some kind of sandwiched fiber, this is my first attempt at this. Any suggestions ? Thanks Bob

-

Hi Guest!

Hi Guest!

If you appreciate British Car Forum and our 25 years of supporting British car enthusiasts with technical and anicdotal information, collected from our thousands of great members, please support us with a low-cost subscription. You can become a supporting member for less than the dues of most car clubs.

There are some perks with a member upgrade!**Upgrade Now**

(PS: Subscribers don't see this gawd-aweful banner

Tips

- We have a special forum called "Member Articles" where you can submit actual articles for consideration for publication. Learn More

- Don't have an Avatar? If not, your avatar will default to the 1st character in your username. Go into "Account Details" to change your Avatar.

- Some basic forum navigation info: click

Hey - did you know if you click on the title of a thread it will take you to the first unread post since you last visited that thread?

- Hey Guest - Is your British Car Club in our Clubs database? If not, send me a PM - Basil

- Looking for a local club? Click the "Clubs" tab above and browse hundreds of clubs world-wide.

- Add Android or iPhone APP: click

- Did you know - any picture or video you add in your posts in any marque-specific forum will also get added to the Media Gallery automatically.

- A few more tips about posting and replying: click

- Hey there Guest - be sure to keep your profile page up to date with interesting info about yourself: learn more

- More tips and tricks on Posting and Replying: click

STOP!! Never post your email address in open forums. Bots can "harvest" your email! If you must share your email use a Private Message or use the

STOP!! Never post your email address in open forums. Bots can "harvest" your email! If you must share your email use a Private Message or use the  smilie in place of the real @

smilie in place of the real @

- Want to mention another member in a post & get their attention? WATCH THIS

- So, you created a "Group" here at BCF and would like to invite other members to join? Watch this!

- Hey Guest - A post a day keeps Basil from visiting you in the small hours and putting a bat up your nightdress!

- Hey Guest - do you know of an upcoming British car event?

Pretty Please - add it to our Events forum(s) and add to the calendar! >> Here's How <<

Pretty Please - add it to our Events forum(s) and add to the calendar! >> Here's How <<

- Hey Guest - you be stylin'

Change the look and feel of the forum to fit your taste. Check it out

- If you run across an inappropriate post, for example a post that breaks our rules or looks like it might be spam, you can report the post to the moderators: Learn More

- If you would like to try some different "looks" or styles for the site, scroll to the very bottom, on the left and click the Style Selector.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Exhaust down pipes

- Thread starter stinky60

- Start date

richberman

Jedi Warrior

Offline

Bob_Spidell

Yoda

Offline

Hoo boy ... this is a known PITA. There are two kinds of gaskets generally available: one type has two copper sheets with some white fibrous material in between, and one has perforated silver metal with black fibrous material in between. I've tried both--repeatedly--and it's a wash IMO. Solid copper gaskets should be best, if you find any please let us all know.

It's difficult to get a good, lasting seal at this joint. The 4-cyl cars had a bracket and clamp anchored by one of the pan bolts that stabilized the (single) downpipe. The 6-cyl cars don't have this, and I think part of the problem is the downpipes vibrate and work the studs, nuts and gasket so eventually you get leaks. I've gotten best results by:

- make sure the studs are in good shape (threads clean, not stretched)

- flat-file (or mill, if you can) the downpipe flanges as flat and smooth as possible (if you have the manifold out do same to it)

- apply high-temp silicone to both sides of the gasket (looks like Rich did this)

- either use new brass nuts or apply anti-seize to the stud threads and double-nut with steel nuts (my preference)

- check the nuts regularly for tightness

It's difficult to get a good, lasting seal at this joint. The 4-cyl cars had a bracket and clamp anchored by one of the pan bolts that stabilized the (single) downpipe. The 6-cyl cars don't have this, and I think part of the problem is the downpipes vibrate and work the studs, nuts and gasket so eventually you get leaks. I've gotten best results by:

- make sure the studs are in good shape (threads clean, not stretched)

- flat-file (or mill, if you can) the downpipe flanges as flat and smooth as possible (if you have the manifold out do same to it)

- apply high-temp silicone to both sides of the gasket (looks like Rich did this)

- either use new brass nuts or apply anti-seize to the stud threads and double-nut with steel nuts (my preference)

- check the nuts regularly for tightness

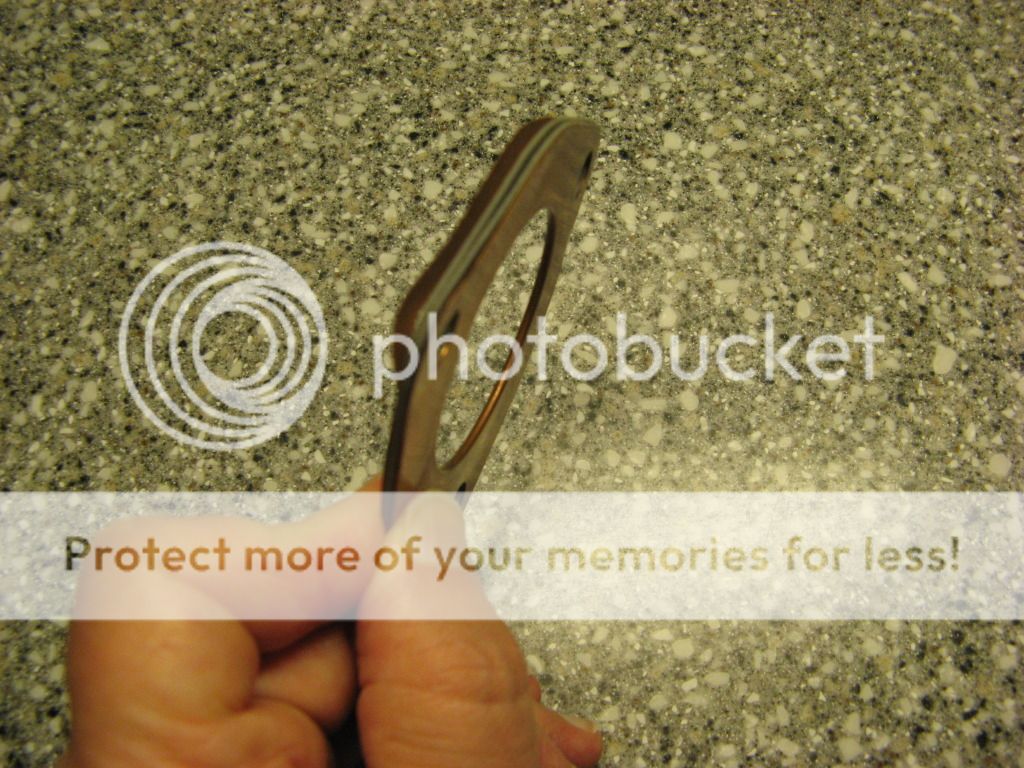

Rich, those are some nice looking pipes, off hand do you know roughly how thick those gaskets were, I can get various thickness sheets of copper, they were not hard to make,Bob I'm going to follow the new brass nuts, and dbl nut them. Tim were those composite with outer copper on both sides? Thanks guys

richberman

Jedi Warrior

Offline

stinky,

I bought them from AHSpares. I did not measure the thickness before installation, sorry.

https://www.ahspares.co.uk/austin-healey/big-healey/Exhaust-Systems/GASKET-pipe-to-manifold-1.aspx They can probably ship them in an envelope regular post.

Downpipes and SS exhaust are the new trophy exhaust from Moss.

I love it!

rich

I bought them from AHSpares. I did not measure the thickness before installation, sorry.

https://www.ahspares.co.uk/austin-healey/big-healey/Exhaust-Systems/GASKET-pipe-to-manifold-1.aspx They can probably ship them in an envelope regular post.

Downpipes and SS exhaust are the new trophy exhaust from Moss.

I love it!

rich

Bob_Spidell

Yoda

Offline

Are these solid copper (can't tell from the pic)?

Bob_Spidell

Yoda

Offline

Thanks.

Johnny

Darth Vader

Offline

Very nice indeed, thanks for sharing. May I ask what kind of clamps did you use? I'd hate to even clamp those lovely pipes.richberman said:

richberman

Jedi Warrior

Offline

Moss includes SS clamps with the pip set. If you look at the other pictures you'll see them. It's a really nice setup! I highly recommend it.

rich

rich

AH3000_DS5

Freshman Member

Offline

Hi,

I have a blowout at the flange on my BT7, so I will replace the down pipes using the SS-pipes, copper sandwich gaskets and brass nuts. The link you indicated no longer exists,

so I think the FRONT PIPE-(front)S.S is partnumber EXS125: https://www.ahspares.co.uk/austin-healey/performance-parts/Exhaust/FRONT-PIPE-frontSS.aspx

and the FRONT PIPE-(rear)S.S is EXS126: https://www.ahspares.co.uk/austin-healey/performance-parts/Exhaust/FRONT-PIPE-rearSS.aspx

My car is a BT7 but I have a BJ8 engine on board with a tricarb. Can anyone explain me the difference between the downpipes for bn4-bj7 and bj8?

many thkx and regards

Pascal

I have a blowout at the flange on my BT7, so I will replace the down pipes using the SS-pipes, copper sandwich gaskets and brass nuts. The link you indicated no longer exists,

so I think the FRONT PIPE-(front)S.S is partnumber EXS125: https://www.ahspares.co.uk/austin-healey/performance-parts/Exhaust/FRONT-PIPE-frontSS.aspx

and the FRONT PIPE-(rear)S.S is EXS126: https://www.ahspares.co.uk/austin-healey/performance-parts/Exhaust/FRONT-PIPE-rearSS.aspx

My car is a BT7 but I have a BJ8 engine on board with a tricarb. Can anyone explain me the difference between the downpipes for bn4-bj7 and bj8?

many thkx and regards

Pascal

British_Recovery

Jedi Warrior

Offline

The spacing down below is different, so it depends on what exhaust you are using. The early single muffler(2 in- 2 out) or the BJ8 system that requires the wider spacing. Order according to the exhaust system.

Bob

Bob

Offline

Hi,

I have a blowout at the flange on my BT7, so I will replace the down pipes using the SS-pipes, copper sandwich gaskets and brass nuts. The link you indicated no longer exists,

so I think the FRONT PIPE-(front)S.S is partnumber EXS125: https://www.ahspares.co.uk/austin-healey/performance-parts/Exhaust/FRONT-PIPE-frontSS.aspx

and the FRONT PIPE-(rear)S.S is EXS126: https://www.ahspares.co.uk/austin-healey/performance-parts/Exhaust/FRONT-PIPE-rearSS.aspx

My car is a BT7 but I have a BJ8 engine on board with a tricarb. Can anyone explain me the difference between the downpipes for bn4-bj7 and bj8?

many thkx and regards

Pascal

If you have a blowout, wouldn't that mean either the flange connection is loose - for instance one of the nuts missing, or that you need new gaskets, rather than replacing the downpipes?

Moss catalog shows the same gaskets for all 6-cylinder cars.

BJ8 downpipes are different because of different BJ8 exhaust system, not anything on the engine or exhaust manifold.