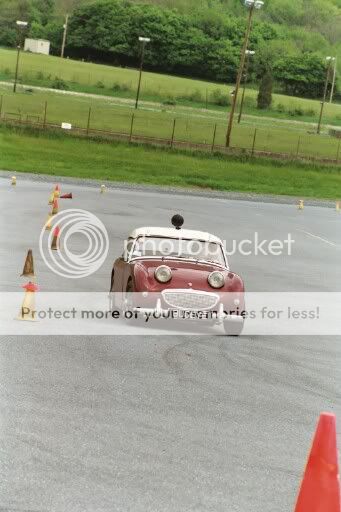

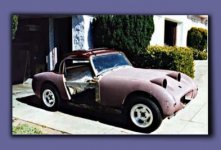

Last weekend, I decided that the Sprite would be a good vehicle for teaching my teenage son to drive a manual trans. A good plan, it seems, except that an attempted 2nd gear, tire-chirping takeoff resulted in a broken axle.

My problem is that the axle is broken at the splined end, in the differential. So far, I've been unsuccessful in driving the broken portion of the axle out of the differential. Using an thin screwdriver, I can pound the broken part out from the inside, but it's hanging up when it's roughly flush with the axle bearing. I can't use a punch due to clearance issues.

Please share any tips or tricks you may know. I sure would like to get this bugger out without disassembling the diff.

My problem is that the axle is broken at the splined end, in the differential. So far, I've been unsuccessful in driving the broken portion of the axle out of the differential. Using an thin screwdriver, I can pound the broken part out from the inside, but it's hanging up when it's roughly flush with the axle bearing. I can't use a punch due to clearance issues.

Please share any tips or tricks you may know. I sure would like to get this bugger out without disassembling the diff.

Hi Guest!

Hi Guest!

smilie in place of the real @

smilie in place of the real @

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

Pretty Please - add it to our Events forum(s) and add to the calendar! >>