Jeepster

Jedi Trainee

Offline

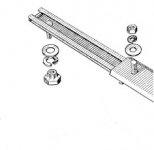

I am in the process of restoring the seat slider mechanisms. They are in a pretty bad state, seized with missing studs etc.

Would anyone have a picture of what a good condition set should look like? I have no idea what length the studs should be ?

Also, what order do the sliders and associated parts fit in the car? Is it seat then sliders then wooden packing piece? The parts suppliers show a tube nut, does this fix the slider to the floor or seat to the slider?

Would anyone have a picture of what a good condition set should look like? I have no idea what length the studs should be ?

Also, what order do the sliders and associated parts fit in the car? Is it seat then sliders then wooden packing piece? The parts suppliers show a tube nut, does this fix the slider to the floor or seat to the slider?

Hi Guest!

Hi Guest!

smilie in place of the real @

smilie in place of the real @

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

Pretty Please - add it to our Events forum(s) and add to the calendar! >>