mgedit

Jedi Knight

Offline

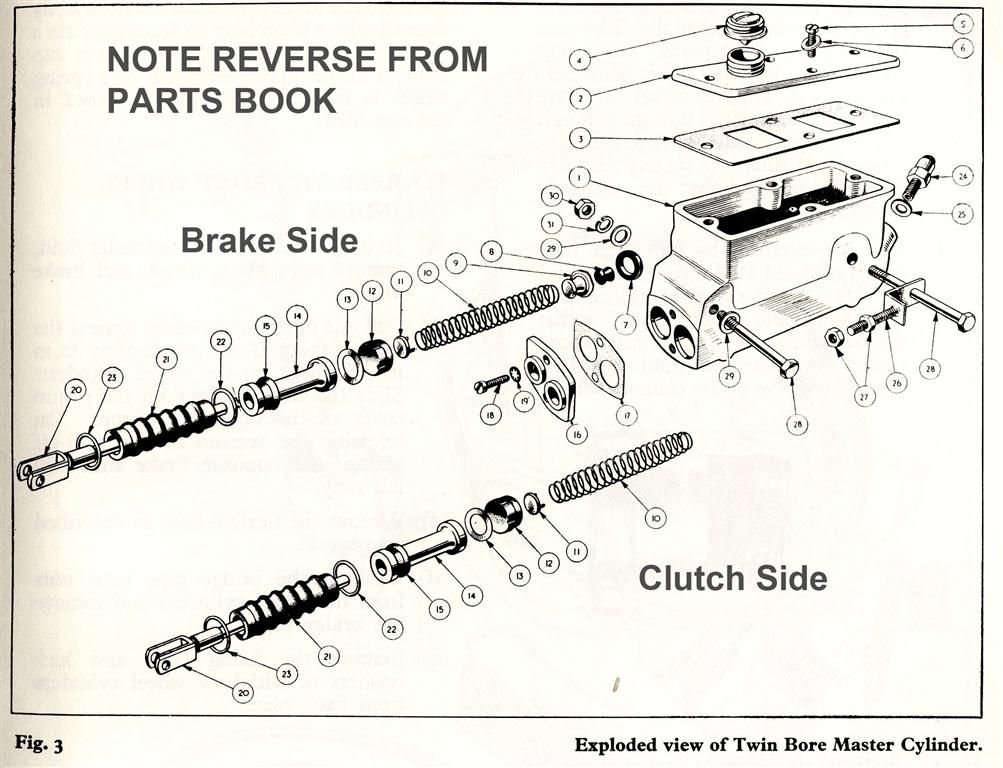

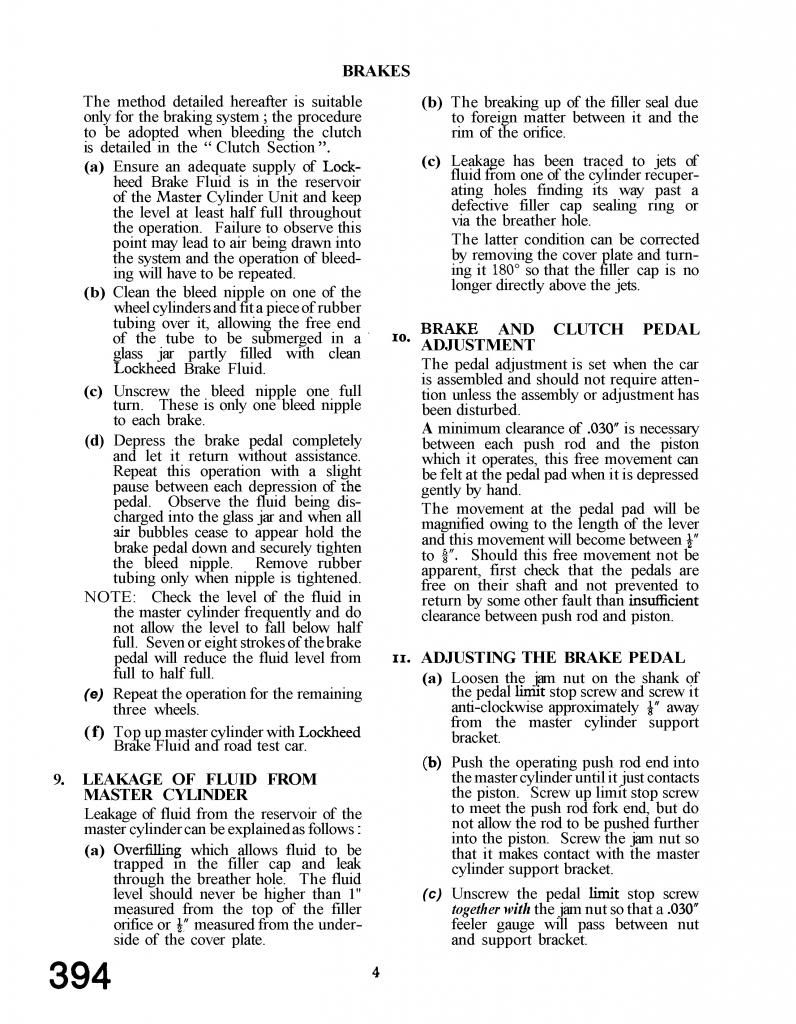

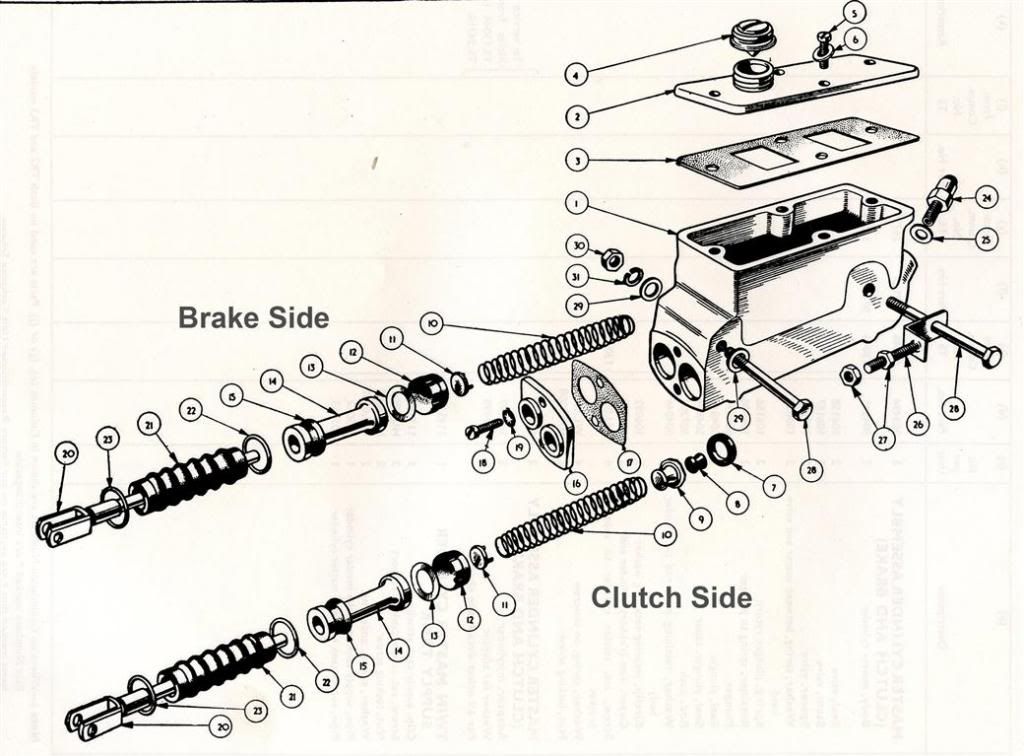

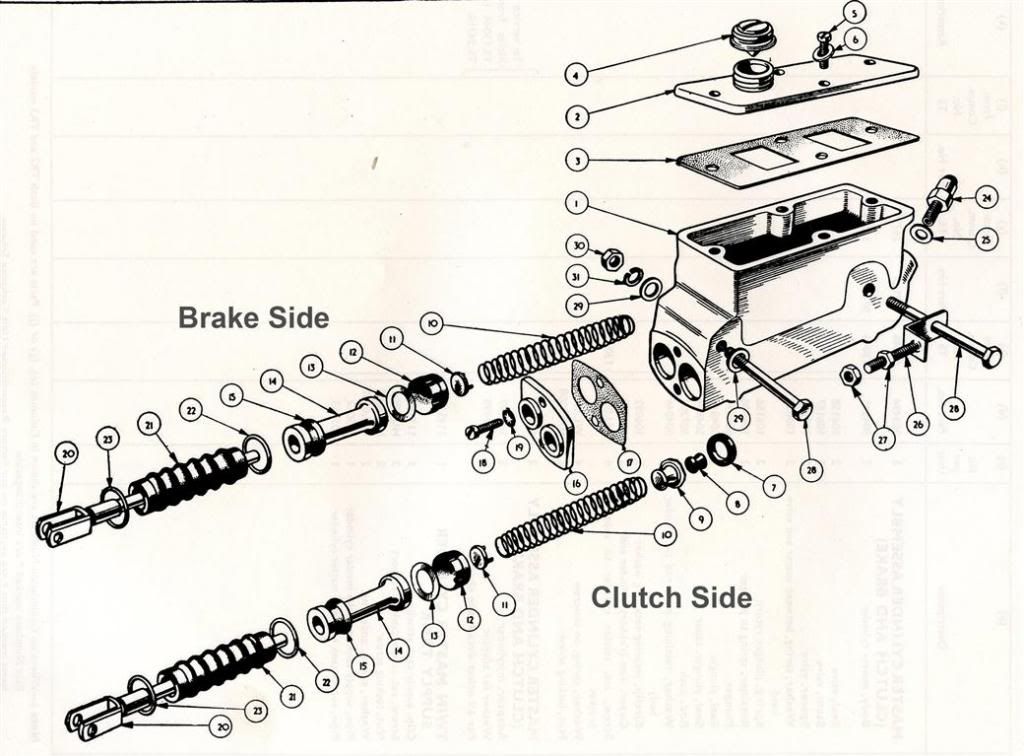

Having issues with recently rebuilt Lockheed master cylinder on my 56 TR3. Initially could not get system to bleed. Bought a suction type bleeder and that did not help. Took cylinder out of car to look at on bench. The piston was not returning after being pushed into bore on brake side (clutch side working just fine). Pushed the piston out with a little compressed air and checked for ridges or other issues in bore. Nothing that I could feel or see (it was resleeved in brass several years before I got the car but never installed). On bench was working fine with many repetitions of pushing in the piston and having it return normally. Back in the car. Bled system with suction bleeder (no need to move piston) and all seemed OK till I got to rear of car and one wheel cylinder was leaking. Ordered new copper washers for banjo connector, and while I waited for parts system enough fluid leaked to empty brake side of master cylinder. Started over again, and now can’t get system to bleed and piston is sticking yet again. Disconnected pipe at brake light switch and used a little compressed air to push piston back to fully retracted position thinking this would get me back to previous state where I had success. However, now can’t get system to start bleeding again. Gentle movement of piston created some air bubbles in MC reservoir. After 3 or 4 gentle strokes no more air, only some fluid being expelled into reservoir so I assume little or no air in MC now, but still won’t bleed.

I am sort of at a loss as what to try next. I can take the MC out again and check it once again for internal issues, but don’t want to do that if I just end up at same stage yet again. Am I missing something? Any ideas on what would cause the piston to not return? This worries me as I don’t see why it should not be pushed back by spring. Was wondering if there is some sort of pressure build up that is overcoming the push of the spring. Ideas and suggestions most welcome and definitely appreciated. Cheers, Mike

I am sort of at a loss as what to try next. I can take the MC out again and check it once again for internal issues, but don’t want to do that if I just end up at same stage yet again. Am I missing something? Any ideas on what would cause the piston to not return? This worries me as I don’t see why it should not be pushed back by spring. Was wondering if there is some sort of pressure build up that is overcoming the push of the spring. Ideas and suggestions most welcome and definitely appreciated. Cheers, Mike

Hi Guest!

Hi Guest!

smilie in place of the real @

smilie in place of the real @

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

Pretty Please - add it to our Events forum(s) and add to the calendar! >>