-

Hey Guest!

Hey Guest!

British Car Forum has been supporting enthusiasts for over 25 years by providing a great place to share our love for British cars. You can support our efforts by upgrading your membership for less than the dues of most car clubs. There are some perks with a member upgrade!**Upgrade Now**

(PS: Upgraded members don't see this banner, nor will you see the Google ads that appear on the site.)

Tips

- We have a special forum called "Member Articles" where you can submit actual articles for consideration for publication. Learn More

- Don't have an Avatar? If not, your avatar will default to the 1st character in your username. Go into "Account Details" to change your Avatar.

- Some basic forum navigation info: click

Hey - did you know if you click on the title of a thread it will take you to the first unread post since you last visited that thread?

- Hey Guest - Is your British Car Club in our Clubs database? If not, send me a PM - Basil

- Looking for a local club? Click the "Clubs" tab above and browse hundreds of clubs world-wide.

- Add Android or iPhone APP: click

- Did you know - any picture or video you add in your posts in any marque-specific forum will also get added to the Media Gallery automatically.

- A few more tips about posting and replying: click

- Hey there Guest - be sure to keep your profile page up to date with interesting info about yourself: learn more

- More tips and tricks on Posting and Replying: click

STOP!! Never post your email address in open forums. Bots can "harvest" your email! If you must share your email use a Private Message or use the

STOP!! Never post your email address in open forums. Bots can "harvest" your email! If you must share your email use a Private Message or use the  smilie in place of the real @

smilie in place of the real @

- Want to mention another member in a post & get their attention? WATCH THIS

- So, you created a "Group" here at BCF and would like to invite other members to join? Watch this!

- Hey Guest - A post a day keeps Basil from visiting you in the small hours and putting a bat up your nightdress!

- Hey Guest - do you know of an upcoming British car event?

Pretty Please - add it to our Events forum(s) and add to the calendar! >> Here's How <<

Pretty Please - add it to our Events forum(s) and add to the calendar! >> Here's How <<

- Hey Guest - you be stylin'

Change the look and feel of the forum to fit your taste. Check it out

- If you run across an inappropriate post, for example a post that breaks our rules or looks like it might be spam, you can report the post to the moderators: Learn More

- If you would like to try some different "looks" or styles for the site, scroll to the very bottom, on the left and click the Style Selector.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Valve Drain Pipe

- Thread starter Rreford

- Start date

WHT

Jedi Hopeful

Offline

Bill, thank you so much - exactly what I needed, they are now removed, bagged and taggedYes, the Oil Pump Bypass Tube/Pipe drains excess oil from the pressure release valve.

And, you can see in both of the slides, it is threaded.

Regards, Bill

Offline

What is that tool n your avatar?Glad to help and hope your engine work goes well!

Regards, Bill

WHT

Jedi Hopeful

Offline

Hi Patrick,

Its a tool for removing and replacing valve springs and valve seals without removing the head. Has 3-axis adjustability for valve stem alignment and will therefore fit most heads. And, can be used to remove and replace valves with the head off.

Very useful for breaking-in rebuilt old British flat tappet engines. You can do the initial startup and break-in using weaker valve springs (or just the outer valve springs), and then install the heavier service springs (and/or inner springs).

Regards, Bill

Its a tool for removing and replacing valve springs and valve seals without removing the head. Has 3-axis adjustability for valve stem alignment and will therefore fit most heads. And, can be used to remove and replace valves with the head off.

Very useful for breaking-in rebuilt old British flat tappet engines. You can do the initial startup and break-in using weaker valve springs (or just the outer valve springs), and then install the heavier service springs (and/or inner springs).

Regards, Bill

Last edited:

Offline

Hi Bill,Hi Patrick,

Its a tool for removing and replacing valve springs and valve seals without removing the head. Has 3-axis adjustability for valve stem alignment and will therefore fit most heads. And, can be used to remove and replace valves with the head off.

Very useful for breaking-in rebuilt old British flat tappet engines. You can do the initial startup and break-in using weaker valve springs (or just the outer valve springs), and then install the heavier service springs (and/or inner springs).

Regards, Bill

My engine wasn’t broken in with the aid of that tool. This is the first time I’ve heard about breaking in a British flat-tappet engine using weaker valve springs too. Not having to remove the head is big plus!

Cheers,

Patrick

WHT

Jedi Hopeful

Offline

Hi Patrick,

Most people don't use break-in springs, except for performance engines. But, reducing load on an older design flat tappet cam during break-in helps (especially with the quality of many parts today).

For example, I checked out 12 of the latest Healey lifters and their cam lobe surfaces are flat (slight taper with NO crowning) and their diameters were often over-sized by up to 0.0015-inches by my measurements; about half of them were tight in the bores. They will need to be sized properly and then matched to the cam lobe profile/taper. However, both their side and lobe contact surface hardness did test within factory specifications.

I broke-in the engine in Barbie's TD with 80 pound seat pressure springs and then replaced them with 130 pound seat pressure springs afterwards. We put a lot of effort into her engine (billet crankshaft and rods, JE forged pistons, porting and custom valves, performance cam, high chrome liners, etc). And, it is a very nice and smooth engine with great performance. The engine machining was done by a shop that builds engines for museum restorations.

Collecting parts for the BJ8 engine now.

Regards, Bill

Most people don't use break-in springs, except for performance engines. But, reducing load on an older design flat tappet cam during break-in helps (especially with the quality of many parts today).

For example, I checked out 12 of the latest Healey lifters and their cam lobe surfaces are flat (slight taper with NO crowning) and their diameters were often over-sized by up to 0.0015-inches by my measurements; about half of them were tight in the bores. They will need to be sized properly and then matched to the cam lobe profile/taper. However, both their side and lobe contact surface hardness did test within factory specifications.

I broke-in the engine in Barbie's TD with 80 pound seat pressure springs and then replaced them with 130 pound seat pressure springs afterwards. We put a lot of effort into her engine (billet crankshaft and rods, JE forged pistons, porting and custom valves, performance cam, high chrome liners, etc). And, it is a very nice and smooth engine with great performance. The engine machining was done by a shop that builds engines for museum restorations.

Collecting parts for the BJ8 engine now.

Regards, Bill

Randy Forbes

Yoda

Offline

Offline

Hi Bill,Hi Patrick,

Most people don't use break-in springs, except for performance engines. But, reducing load on an older design flat tappet cam during break-in helps (especially with the quality of many parts today).

For example, I checked out 12 of the latest Healey lifters and their cam lobe surfaces are flat (slight taper with NO crowning) and their diameters were often over-sized by up to 0.0015-inches by my measurements; about half of them were tight in the bores. They will need to be sized properly and then matched to the cam lobe profile/taper. However, both their side and lobe contact surface hardness did test within factory specifications.

I broke-in the engine in Barbie's TD with 80 pound seat pressure springs and then replaced them with 130 pound seat pressure springs afterwards. We put a lot of effort into her engine (billet crankshaft and rods, JE forged pistons, porting and custom valves, performance cam, high chrome liners, etc). And, it is a very nice and smooth engine with great performance. The engine machining was done by a shop that builds engines for museum restorations.

Collecting parts for the BJ8 engine now.

Regards, Bill

I was very picky with my camshaft & lifters when I overhauled my engine and I ended up going with Elgin. I had three suppliers I selected and interviewed them. Prices varied. Unfortunately, I had to eliminate two of the companies I sent questions to because they did not answer all the questions. Elgin did and when I call Dima, he explained his process in detail. He knew the Austin engines quite well and checking for hardness, etc.

When are you going to rebuild your engine?

Cheers,

Patrick

Last edited:

WHT

Jedi Hopeful

Offline

Hi Patrick,

We are planning to start the full rebuild in about 24 months.

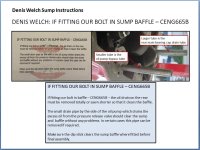

In the meantime, will make a few changes this spring before the best driving season starts. I was doing a tuneup a few weeks ago and noticed one of the rocker arm spacer springs was starting to cut into the rocker shaft. And, decided to rebuild the assembly using the Denis Welch rocker arm spacers and hardened shaft. Waiting on a few shims now to center the rocker arms with a slight offset and adjust spacer clearances.

I really like the rocker arm spacers; there is virtually no friction and everything can be positioned correctly.

Of course, thought this was a good time to check the cam followers and cam lobes. Two of the followers had one very small pit and I am changing them too before any damage is done. The cam is still in great shape with full lobe lift at every valve location (0.261-inches). The latest lifters have good hardening, but the machining was off as sold (crowning and diameter).

Two of the followers had one very small pit and I am changing them too before any damage is done. The cam is still in great shape with full lobe lift at every valve location (0.261-inches). The latest lifters have good hardening, but the machining was off as sold (crowning and diameter).

Rocker Arms Unlimited did the rocker arm rebuild, checked over and crowned new lifters and also checked their hardness. Will use Smith Brothers pushrods (with new adjusters) so everything north of the cam is in like new condition.

I'll decide on the cam to be used in the full rebuild later based on recommendations like yours, but will keep it close to BJ8 specifications. I have a set of MGC cam followers with good hardness and crowning; and Smith Brothers are making the required lifters for those too. Might use them in the full rebuild. They are used more in racing as you know, but some builders say they are not as durable long term on the street.

Regards, Bill

We are planning to start the full rebuild in about 24 months.

In the meantime, will make a few changes this spring before the best driving season starts. I was doing a tuneup a few weeks ago and noticed one of the rocker arm spacer springs was starting to cut into the rocker shaft. And, decided to rebuild the assembly using the Denis Welch rocker arm spacers and hardened shaft. Waiting on a few shims now to center the rocker arms with a slight offset and adjust spacer clearances.

I really like the rocker arm spacers; there is virtually no friction and everything can be positioned correctly.

Of course, thought this was a good time to check the cam followers and cam lobes.

Rocker Arms Unlimited did the rocker arm rebuild, checked over and crowned new lifters and also checked their hardness. Will use Smith Brothers pushrods (with new adjusters) so everything north of the cam is in like new condition.

I'll decide on the cam to be used in the full rebuild later based on recommendations like yours, but will keep it close to BJ8 specifications. I have a set of MGC cam followers with good hardness and crowning; and Smith Brothers are making the required lifters for those too. Might use them in the full rebuild. They are used more in racing as you know, but some builders say they are not as durable long term on the street.

Regards, Bill

Attachments

Last edited:

Bob_Spidell

Yoda

Offline

With no data whatsoever, I persuaded myself that a gun-drilled cam that continuously feeds oil to each lobe and the oil pump drive gear is a good idea (all the ZDDP in the world won't help much if it's not getting where it's needed). I got the gun-drilled DWR1 cam, which DW claims is 'a bit better than a stock BJ8' cam. I like it; slightly lumpy but steady idle at 700-750RPM and pulls strongly up to 5K RPM, above which I don't need--or want--to push the engine very often. There is another vendor with a gun-drilled cam, but I don't have a link or remember the company.

![IMG_2926[1].JPG](/community/data/attachments/72/72407-8b11368296bf84e69a6c1559f3a42c91.jpg)