Hello Everyone,

I'm working on the front suspension of my 1960 Mark I and have run into a few issues (the suspension unit, upper and lower arms, hub, and brake unit have all been removed from the vehicle):

1. I am unable to remove the nut on the top of the kingpin. I have tried heating it and but with force this only turns the entire kingpin within the lower trunion;

2. I am unable to remove the nuts from the 5 bolts that hold the brake disk to the hub. The nuts appear to have some sort of locking washer on the top of the nut that holds the nut in place and I can't find a way to remove the lock washer; and

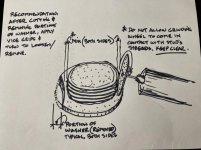

3. I do not have the tool to remove the dust cap inside the front hub. I'm thinking there has to be a way to do this without the special tool.

I appreciate any advice you all can offer on any or all of these items. Thanks,

I'm working on the front suspension of my 1960 Mark I and have run into a few issues (the suspension unit, upper and lower arms, hub, and brake unit have all been removed from the vehicle):

1. I am unable to remove the nut on the top of the kingpin. I have tried heating it and but with force this only turns the entire kingpin within the lower trunion;

2. I am unable to remove the nuts from the 5 bolts that hold the brake disk to the hub. The nuts appear to have some sort of locking washer on the top of the nut that holds the nut in place and I can't find a way to remove the lock washer; and

3. I do not have the tool to remove the dust cap inside the front hub. I'm thinking there has to be a way to do this without the special tool.

I appreciate any advice you all can offer on any or all of these items. Thanks,

Hi Guest!

Hi Guest!

smilie in place of the real @

smilie in place of the real @

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

Pretty Please - add it to our Events forum(s) and add to the calendar! >>