Offline

As I am sure many of you did, I enjoyed reading "A visit to the MG Austin-Healey factory at Abingdon, June 1967" by James Blohm in the latest issue of The Healey Marque.

Those who have restored their cars or pulled and replaced their engines have often wondered how much of the complete engine assembly can I "drop-in" the engine bay with an engine hoist. The subject has also been discussed here before. Of course, there is always a difference between "how much can I drop-in from above" versus "how much do I want to drop-in from above?" Fresh paint tends to make us all cautious.

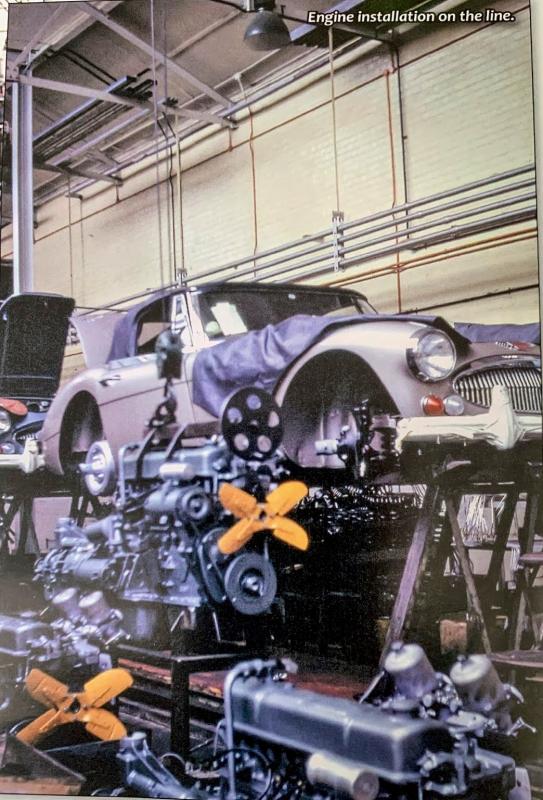

I have seen factory assembly line photos before, but the one in the article referenced above is one of the better ones I have seen. I would be curious what others of you observe and think. One cannot see the left side of the engine in the photo, but it is clear that the inlet manifold and carbs, sans air cleaners, are mounted on the engine. The right side of the engine is clearer showing the dynamo, coil, distributor, ignition wiring, fan and fan belt, starter and RH motor mount. I think the vacuum line from carb to distributor is also in view? We cannot tell if the LH motor mount is on the engine or not. I would assume that the exhaust manifolds are mounted but one cannot tell for sure from the photo. Clearly the exhaust downpipes would have to wait until the engine was in the car.

What are your conclusions? Interesting that the two motors showing the radiator fans have the fans in identical positions. I don't see the radiator poking its head tank above the front lip of the shroud, so as I would expect it was probably inserted later in the process. It is hard to tell in the photo but it looks like the coolant hoses to/from the radiator are not installed on the engine.

Again, curious about your observations.

Lin

Those who have restored their cars or pulled and replaced their engines have often wondered how much of the complete engine assembly can I "drop-in" the engine bay with an engine hoist. The subject has also been discussed here before. Of course, there is always a difference between "how much can I drop-in from above" versus "how much do I want to drop-in from above?" Fresh paint tends to make us all cautious.

I have seen factory assembly line photos before, but the one in the article referenced above is one of the better ones I have seen. I would be curious what others of you observe and think. One cannot see the left side of the engine in the photo, but it is clear that the inlet manifold and carbs, sans air cleaners, are mounted on the engine. The right side of the engine is clearer showing the dynamo, coil, distributor, ignition wiring, fan and fan belt, starter and RH motor mount. I think the vacuum line from carb to distributor is also in view? We cannot tell if the LH motor mount is on the engine or not. I would assume that the exhaust manifolds are mounted but one cannot tell for sure from the photo. Clearly the exhaust downpipes would have to wait until the engine was in the car.

What are your conclusions? Interesting that the two motors showing the radiator fans have the fans in identical positions. I don't see the radiator poking its head tank above the front lip of the shroud, so as I would expect it was probably inserted later in the process. It is hard to tell in the photo but it looks like the coolant hoses to/from the radiator are not installed on the engine.

Again, curious about your observations.

Lin

Hi Guest!

Hi Guest!

smilie in place of the real @

smilie in place of the real @

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

Pretty Please - add it to our Events forum(s) and add to the calendar! >>