-

Hi Guest!

Hi Guest!

If you appreciate British Car Forum and our 25 years of supporting British car enthusiasts with technical and anicdotal information, collected from our thousands of great members, please support us with a low-cost subscription. You can become a supporting member for less than the dues of most car clubs.

There are some perks with a member upgrade!**Upgrade Now**

(PS: Subscribers don't see this gawd-aweful banner

Tips

- We have a special forum called "Member Articles" where you can submit actual articles for consideration for publication. Learn More

- Don't have an Avatar? If not, your avatar will default to the 1st character in your username. Go into "Account Details" to change your Avatar.

- Some basic forum navigation info: click

Hey - did you know if you click on the title of a thread it will take you to the first unread post since you last visited that thread?

- Hey Guest - Is your British Car Club in our Clubs database? If not, send me a PM - Basil

- Looking for a local club? Click the "Clubs" tab above and browse hundreds of clubs world-wide.

- Add Android or iPhone APP: click

- Did you know - any picture or video you add in your posts in any marque-specific forum will also get added to the Media Gallery automatically.

- A few more tips about posting and replying: click

- Hey there Guest - be sure to keep your profile page up to date with interesting info about yourself: learn more

- More tips and tricks on Posting and Replying: click

STOP!! Never post your email address in open forums. Bots can "harvest" your email! If you must share your email use a Private Message or use the

STOP!! Never post your email address in open forums. Bots can "harvest" your email! If you must share your email use a Private Message or use the  smilie in place of the real @

smilie in place of the real @

- Want to mention another member in a post & get their attention? WATCH THIS

- So, you created a "Group" here at BCF and would like to invite other members to join? Watch this!

- Hey Guest - A post a day keeps Basil from visiting you in the small hours and putting a bat up your nightdress!

- Hey Guest - do you know of an upcoming British car event?

Pretty Please - add it to our Events forum(s) and add to the calendar! >> Here's How <<

Pretty Please - add it to our Events forum(s) and add to the calendar! >> Here's How <<

- Hey Guest - you be stylin'

Change the look and feel of the forum to fit your taste. Check it out

- If you run across an inappropriate post, for example a post that breaks our rules or looks like it might be spam, you can report the post to the moderators: Learn More

- If you would like to try some different "looks" or styles for the site, scroll to the very bottom, on the left and click the Style Selector.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Gasket, Inlet Manifold to Exhaust Manifold BJ8

- Thread starter AUSMHLY

- Start date

AUSMHLY

Yoda

Offline

Not certain but I think it's to allow for the slight movement caused by the different expansion rates of cast iron and aluminum, same reason there is a metal side to the manifold to head gasket.

The engine gasket has fiber sandwiched between metal. I'll assume metal exterior for heat and the purpose of the gasket is to seal any air leakage.

The gasket that's between the Inlet/Exhaust manifolds has metal sandwiched between fiber. Why is it the reverse of the engine gasket?

Interesting that both the Inlet and Exhaust manifolds have a square impression (where the gasket goes) that seems to serve no purpose.

Online

I think it provides some controlled heat transfer from the exhaust to intake to keep the fuel from condensing in the intake manifold.

Bob_Spidell

Yoda

Offline

I think it provides some controlled heat transfer from the exhaust to intake to keep the fuel from condensing in the intake manifold.

This (at least, it's the best explanation). The gasket in the OP's photo is too thin, they used to be about a quarter inch think and appeared to be made of a material that would moderate heat transfer. No idea why they now sell a thin one that won't fill the gap (unless you stack a few). At any rate, you can probably get away without them, they usually degrade and disappear eventually anyway. Don't torque the through-bolts until you've torqued the manifolds down, and then just enough to keep the bolts from working loose; I think the only reason they're there is to keep the gaskets in place.

AUSMHLY

Yoda

Offline

This (at least, it's the best explanation). The gasket in the OP's photo is too thin, they used to be about a quarter inch think and appeared to be made of a material that would moderate heat transfer. No idea why they now sell a thin one that won't fill the gap (unless you stack a few). At any rate, you can probably get away without them, they usually degrade and disappear eventually anyway. Don't torque the through-bolts until you've torqued the manifolds down, and then just enough to keep the bolts from working loose; I think the only reason they're there is to keep the gaskets in place.

New Gasket in photo is from Moss. Are there torque setting for both manifolds?

Bob_Spidell

Yoda

Offline

Nothing in the shop manuals; I think they're 7/16" studs (not sure); so about 40-50ft-lbs should work.

Offline

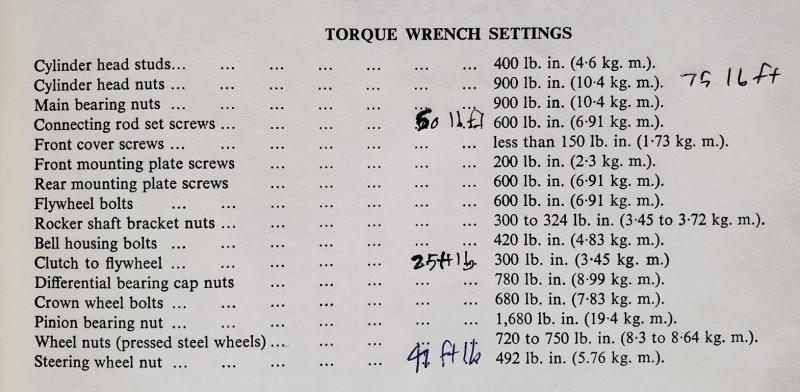

Below are the required torques from the manual. Divide lb in by 12 for lb ft.

If one insists on torquing everything, suggest downloading a torque values chart from google images and using the standard values for that size thread.

IMO using a torque wrench where not needed is overkill - exception: captive nuts such as front shocks and anti-roll bar mounts.

FWIW, the manifold studs are 3/8"-24

Wrench sizes and their bolt sizes:

7/16" - 1/4"

1/2" - 5/16"

9/16" - 3/8"

5/8" - 7/16"

If one insists on torquing everything, suggest downloading a torque values chart from google images and using the standard values for that size thread.

IMO using a torque wrench where not needed is overkill - exception: captive nuts such as front shocks and anti-roll bar mounts.

FWIW, the manifold studs are 3/8"-24

Wrench sizes and their bolt sizes:

7/16" - 1/4"

1/2" - 5/16"

9/16" - 3/8"

5/8" - 7/16"