Volker,

Although the length of the left spring in the picture is longer, it may be weaker in resistance to deflection and, when compressed in the car and under load, could cause the car to drop further. Since the spring is held to a fixed length when installed in the car, its initial free length has little significance to its compression potential. Your current (right pictured) spring has been compressed over years of deflections and lost some of its length. However, the new unused left spring has not been compressed and will compress when installed to provide proper resistance. Additionally, as with new rear springs, you may expect that the new front springs may take time to settle in to a final height.

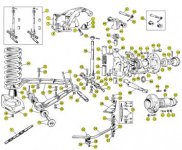

One last thought. Have you rebuilt your front suspension. If so, I would check to see if your bushings (upper and lower sets) are not binding and causing the suspension not to fully settle.

Ray(64BJ8P1)

Hi Guest!

Hi Guest!

smilie in place of the real @

smilie in place of the real @

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

Pretty Please - add it to our Events forum(s) and add to the calendar! >>