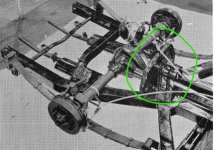

"Nichola" IMHO...the main source of rear chassis twist and flex originates from the area outlined.

I presume you have jigged your chassis to confirm that it is now "straight".

There are many differing opinions as to methods of rectifying the problem, and depends if you want to have the rear chassis looking concours in it's structure.

I am not a concours person or an engineer and this is my scenario based on what I did to strengthen the frame of my TR4 with IRS with the body on. Obviously I could have done a better job if I was working on a bare frame.

Weld a 65mm x 8mm x 900mm plates into the inside of the two main frame rails, centered on the outlined area. 65mm fits nice and snug between the top and bottom of the rails.

Boxed the rear suspension cross member upright supports to the chassis rails.

Remove [top] and bottom cruciform plates and weld in much larger/stronger plates from one outer chassis rail to the other side, with small cutouts to access the T/A mount bolts.

I have this additional arch [as seen on pic] on my TR,and welded braces from the top of it over to the rear suspension cross member, creating a box like figure to help strengthen the weak section that exists between the mid and rear chassis rails.

Like wise braces from the R/S cross member to the rear axle crossmember.

Some members will probably say that the above methods are OTT and put additional stress on other areas of the chassis. However there has to be ways of improving the original poor chassis design.

Anything is possible...but miracles take a bit longer...

Hi Guest!

Hi Guest!

smilie in place of the real @

smilie in place of the real @

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

Pretty Please - add it to our Events forum(s) and add to the calendar! >>