Hi all, I just measured the end float on my newly acquired TR3B. 8 thousands. Went looking for oversize thrust washers, and Moss is NA, didn't see any at roadster factory, Victoria british only had standard size, customthrustwashers doesn't list for TR3. Can anyone point me in the right direction? thx

-

Hi Guest!

Hi Guest!

If you appreciate British Car Forum and our 25 years of supporting British car enthusiasts with technical and anicdotal information, collected from our thousands of great members, please support us with a low-cost subscription. You can become a supporting member for less than the dues of most car clubs.

There are some perks with a member upgrade!**Upgrade Now**

(PS: Subscribers don't see this gawd-aweful banner

Tips

- We have a special forum called "Member Articles" where you can submit actual articles for consideration for publication. Learn More

- Don't have an Avatar? If not, your avatar will default to the 1st character in your username. Go into "Account Details" to change your Avatar.

- Some basic forum navigation info: click

Hey - did you know if you click on the title of a thread it will take you to the first unread post since you last visited that thread?

- Hey Guest - Is your British Car Club in our Clubs database? If not, send me a PM - Basil

- Looking for a local club? Click the "Clubs" tab above and browse hundreds of clubs world-wide.

- Add Android or iPhone APP: click

- Did you know - any picture or video you add in your posts in any marque-specific forum will also get added to the Media Gallery automatically.

- A few more tips about posting and replying: click

- Hey there Guest - be sure to keep your profile page up to date with interesting info about yourself: learn more

- More tips and tricks on Posting and Replying: click

STOP!! Never post your email address in open forums. Bots can "harvest" your email! If you must share your email use a Private Message or use the

STOP!! Never post your email address in open forums. Bots can "harvest" your email! If you must share your email use a Private Message or use the  smilie in place of the real @

smilie in place of the real @

- Want to mention another member in a post & get their attention? WATCH THIS

- So, you created a "Group" here at BCF and would like to invite other members to join? Watch this!

- Hey Guest - A post a day keeps Basil from visiting you in the small hours and putting a bat up your nightdress!

- Hey Guest - do you know of an upcoming British car event?

Pretty Please - add it to our Events forum(s) and add to the calendar! >> Here's How <<

Pretty Please - add it to our Events forum(s) and add to the calendar! >> Here's How <<

- Hey Guest - you be stylin'

Change the look and feel of the forum to fit your taste. Check it out

- If you run across an inappropriate post, for example a post that breaks our rules or looks like it might be spam, you can report the post to the moderators: Learn More

- If you would like to try some different "looks" or styles for the site, scroll to the very bottom, on the left and click the Style Selector.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

TR2/3/3A where to buy oversize thrust washers for TR3B?

- Thread starter Bruce100

- Start date

Offline

Scott helm make those?

YES, he will be able to take care of them as he does custom sizes. Used him for my thrust washers and he is a pleasure to deal with.

customthrustwashers.com

Last edited:

Offline

Scott's pricing will be more than the catalog guys but I think the material he uses is better. Obviously that is open for everyone's personal opinion.

Note: I don't think he uses solid brass... it's a different alloy; check his site for exact material or just give him a call.

I just checked Scott's website and it looks like he uses a bronze alloy

Note: I don't think he uses solid brass... it's a different alloy; check his site for exact material or just give him a call.

I just checked Scott's website and it looks like he uses a bronze alloy

I had an email exchange with Scott - he doesn't do TR3 yet, as they require a different manufacturing process, and he isn't tooled for it. Assumption is that there is a tab as opposed to that of a TR6. He is interested, and would like a picture. Anyone have a photo of TR3B/TR4 thrust washers I can send him? TR3A as well, while we are at it?

TR3driver

Great Pumpkin - R.I.P

Offline

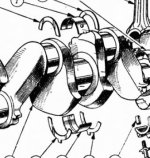

Yes, there is a locating tab, but only on one half. The other half cannot have the tab. Washers are the same for all TR2-TR4A. Sorry I don't have a good photo, but here is part of the diagram from the parts cataloge.

Personally, I have a hard time seeing a bronze alloy as being better in this application. The stock thrust washers are the same tri-metal design as used for rod and main bearings. That design has been around for a very long time and is still in use today (although most makers have gone to cheaper materials that aren't as good but "good enough"). The TR6 motor does have a problem with thrust washers, apparently a combination of lack of thrust surface (the wet liner 4s have twice as much thrust surface) and a crankshaft that flexes a good deal at high rpm. Kas Kastner once measured something like 5/8" deflection at the flywheel!

But the TR3 motor does not seem to suffer the same issues, and in fact the thrust washers normally outlast the other bearings by a large margin as long as the oil is kept clean. I always change them when doing the main bearings, but they generally are not worn out even when the mains are worn into the copper backing.

Personally, I have a hard time seeing a bronze alloy as being better in this application. The stock thrust washers are the same tri-metal design as used for rod and main bearings. That design has been around for a very long time and is still in use today (although most makers have gone to cheaper materials that aren't as good but "good enough"). The TR6 motor does have a problem with thrust washers, apparently a combination of lack of thrust surface (the wet liner 4s have twice as much thrust surface) and a crankshaft that flexes a good deal at high rpm. Kas Kastner once measured something like 5/8" deflection at the flywheel!

But the TR3 motor does not seem to suffer the same issues, and in fact the thrust washers normally outlast the other bearings by a large margin as long as the oil is kept clean. I always change them when doing the main bearings, but they generally are not worn out even when the mains are worn into the copper backing.

I have 8 thousandths end float. A couple of people have said that is not to worry on a TR3B. I bought it single owner, the odometer reads 89k (though I do not know if that is accurate, PO has alzheimers). If all else checks out ok - compression, oil pressure, etc., I'd like to just monitor for a few years till I rebuild. Don't put a lot of miles on my TRs - a few thou a year. What do you think?

Tim Tucker

Jedi Trainee

Offline

Crankshaft end float 0·004 - 0·006" (desirable)

Mfg... 0·0048 - 0·0117"

Wear limit .. 0 ·015"

From the Bentley.

Couldn't agree more. if it runs/drive good then enjoy the car! I think 8 mils is a long way from getting into trouble. IMO.

I have several sets. If Scott just needs a template to start making them, I would be willing to send him a set. Get me an address. Mine came from TRF.

Best of luck on your new car. Enjoy! It's spring here in the south...cold and spitting snow... Go figure?

Go figure?

Tim

Mfg... 0·0048 - 0·0117"

Wear limit .. 0 ·015"

From the Bentley.

Couldn't agree more. if it runs/drive good then enjoy the car! I think 8 mils is a long way from getting into trouble. IMO.

I have several sets. If Scott just needs a template to start making them, I would be willing to send him a set. Get me an address. Mine came from TRF.

Best of luck on your new car. Enjoy! It's spring here in the south...cold and spitting snow...

Tim

TR3driver

Great Pumpkin - R.I.P

Offline

All clear now? "The Bentley" is just a reprint of the factory workshop manual plus an early version of the owner's manual; so it has the same information. For your car, you'll want the 6th edition of the owner's manual (titled Practical Hints for the Maintenance of the Triumph T.R.3) which you can download from

https://docs.google.com/file/d/0B2H...M2U2LWJhYWUtMjEyZDgxMzUyNzUw/edit?usp=sharing

Used to be TRF sold reprints at a very reasonable price, but apparently they don't have them any more.

https://docs.google.com/file/d/0B2H...M2U2LWJhYWUtMjEyZDgxMzUyNzUw/edit?usp=sharing

Used to be TRF sold reprints at a very reasonable price, but apparently they don't have them any more.

Tim Tucker

Jedi Trainee

Offline

Bruce,

I actually copied that from the TR4-4A manual. Glad to know they agree... The TRactor motor sure is tough. I bought my current TR4 in 1981. The crankpin-big end rod clearance was so great you could EASILY see it and feel it. But it had stayed together. That was 30+ years ago. I would have hated to have known the end float number. I agree with others: monitor you crank end play and enjoy your car. Pictures of the car?

The TRactor motor sure is tough. I bought my current TR4 in 1981. The crankpin-big end rod clearance was so great you could EASILY see it and feel it. But it had stayed together. That was 30+ years ago. I would have hated to have known the end float number. I agree with others: monitor you crank end play and enjoy your car. Pictures of the car?

Tim

I actually copied that from the TR4-4A manual. Glad to know they agree...

Tim