tosoutherncars

Jedi Knight

Offline

Well, my DGV and higher compression have upped the power, but I'm getting a stumble on accelleration... sometimes. And the vendor that sells DGVs online is adamant that they will not run well on either a) mechanical pumps with pressure regulators, or b) Facet-style electric pumps.

So, time to install the Carter... model 4070, rotary vane-style, high volume, low pressure. This, and no regulator, is *supposed* to be the ideal setup. Time will tell.

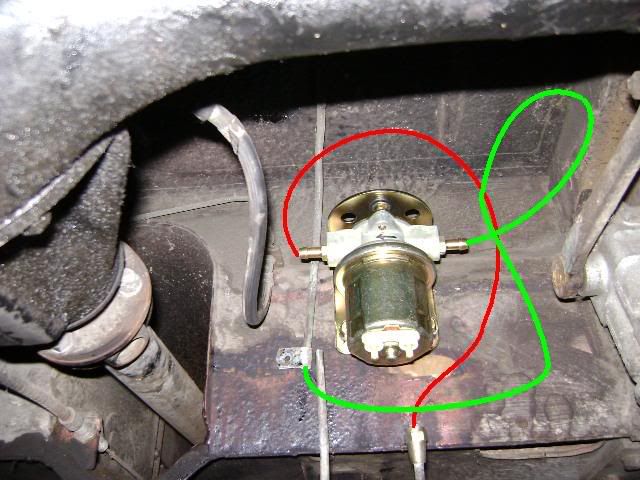

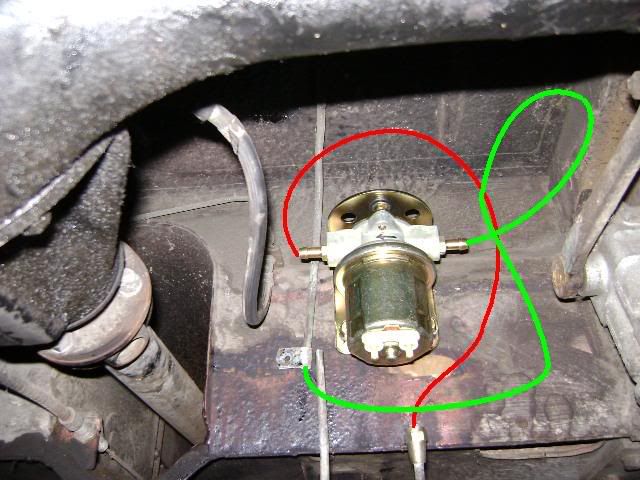

Here's the rear bulkhead, which is where I'm mounting the pump.

On the right is the return line from the engine bay, which I'm no longer using. I disconnected the fittings, both here and at the condensor (right side of trunk) and removed the piece that runs over the axle.

Oh, you can see that there is a ridge running across the bulkhead. there's a captive bolt, originally used to hold down those two fuel lines. That's what I'm using for the top bolt to hold on the Carter.

Here's what I'm using... the Carter 4070

Thankfully, my local big box car parts place had slightly smaller fuel fittings in their nuts & bolts bin. Smaller is on the pump, original beside it for comparison. Oh, and a clear filter I'll be installing... somewhere. (?)

And here it is in all its glory. Because the top bolt is on the ridge, I slipped a large nut between the cage and the bulkhead, just to keep it plumb. A dab of sealant, fender washer and lock washer on each.

Because the top bolt is on the ridge, I slipped a large nut between the cage and the bulkhead, just to keep it plumb. A dab of sealant, fender washer and lock washer on each.

Impossible to tell from the photo, but the way the mounting kit fits, the bolts, even when fully tight, only squeeze the rubber donuts very loosely. With light pressure, you can move the pump slightly back and forth.

And the plan, roughly, is this...

Tank to 'IN' side, 'OUT' side to (former) vent line. Vent line exits...

...right behind the carb. Installed a spacer to raise it up a bit, and it's plumbed in already. Might put the filter up here. Frankly, I don't think I have that much crap in my tank. And I think I'd rather replace a fuel pump than rebuild that carb!

So, time to install the Carter... model 4070, rotary vane-style, high volume, low pressure. This, and no regulator, is *supposed* to be the ideal setup. Time will tell.

Here's the rear bulkhead, which is where I'm mounting the pump.

On the right is the return line from the engine bay, which I'm no longer using. I disconnected the fittings, both here and at the condensor (right side of trunk) and removed the piece that runs over the axle.

Oh, you can see that there is a ridge running across the bulkhead. there's a captive bolt, originally used to hold down those two fuel lines. That's what I'm using for the top bolt to hold on the Carter.

Here's what I'm using... the Carter 4070

Thankfully, my local big box car parts place had slightly smaller fuel fittings in their nuts & bolts bin. Smaller is on the pump, original beside it for comparison. Oh, and a clear filter I'll be installing... somewhere. (?)

And here it is in all its glory.

Impossible to tell from the photo, but the way the mounting kit fits, the bolts, even when fully tight, only squeeze the rubber donuts very loosely. With light pressure, you can move the pump slightly back and forth.

And the plan, roughly, is this...

Tank to 'IN' side, 'OUT' side to (former) vent line. Vent line exits...

...right behind the carb. Installed a spacer to raise it up a bit, and it's plumbed in already. Might put the filter up here. Frankly, I don't think I have that much crap in my tank. And I think I'd rather replace a fuel pump than rebuild that carb!

Hi Guest!

Hi Guest!

smilie in place of the real @

smilie in place of the real @

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

Pretty Please - add it to our Events forum(s) and add to the calendar! >>