I haven't adjusted my BJ8 valves in a couple of years. In the past I have bumped the starter with the solenoid but that is really hit or miss. I have never been able to turn the crank on the front of the engine with a bar but also did not take out the plugs when I tried. Shall I take out the plugs, put the car in gear and move the car to find the cam position for each adjustment. I have never tried this method before. Suggestions please.

-

Hi Guest!

Hi Guest!

If you appreciate British Car Forum and our 25 years of supporting British car enthusiasts with technical and anicdotal information, collected from our thousands of great members, please support us with a low-cost subscription. You can become a supporting member for less than the dues of most car clubs.

There are some perks with a member upgrade!**Upgrade Now**

(PS: Subscribers don't see this gawd-aweful banner

Tips

- We have a special forum called "Member Articles" where you can submit actual articles for consideration for publication. Learn More

- Don't have an Avatar? If not, your avatar will default to the 1st character in your username. Go into "Account Details" to change your Avatar.

- Some basic forum navigation info: click

Hey - did you know if you click on the title of a thread it will take you to the first unread post since you last visited that thread?

- Hey Guest - Is your British Car Club in our Clubs database? If not, send me a PM - Basil

- Looking for a local club? Click the "Clubs" tab above and browse hundreds of clubs world-wide.

- Add Android or iPhone APP: click

- Did you know - any picture or video you add in your posts in any marque-specific forum will also get added to the Media Gallery automatically.

- A few more tips about posting and replying: click

- Hey there Guest - be sure to keep your profile page up to date with interesting info about yourself: learn more

- More tips and tricks on Posting and Replying: click

STOP!! Never post your email address in open forums. Bots can "harvest" your email! If you must share your email use a Private Message or use the

STOP!! Never post your email address in open forums. Bots can "harvest" your email! If you must share your email use a Private Message or use the  smilie in place of the real @

smilie in place of the real @

- Want to mention another member in a post & get their attention? WATCH THIS

- So, you created a "Group" here at BCF and would like to invite other members to join? Watch this!

- Hey Guest - A post a day keeps Basil from visiting you in the small hours and putting a bat up your nightdress!

- Hey Guest - do you know of an upcoming British car event?

Pretty Please - add it to our Events forum(s) and add to the calendar! >> Here's How <<

Pretty Please - add it to our Events forum(s) and add to the calendar! >> Here's How <<

- Hey Guest - you be stylin'

Change the look and feel of the forum to fit your taste. Check it out

- If you run across an inappropriate post, for example a post that breaks our rules or looks like it might be spam, you can report the post to the moderators: Learn More

- If you would like to try some different "looks" or styles for the site, scroll to the very bottom, on the left and click the Style Selector.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Valve adjustment and easiest way set cam position

- Thread starter Goldie

- Start date

Bob_Spidell

Yoda

Offline

I use the 'Rule of 13' for my BJ8 ('Rule of 9' for the BN2):

1) Bump the starter until valve# 12 is at 'rock' (on the nose of the lobe) as close as possible, then put the car in 4th and move a front wheel, if necessary to get closer (it's not absolutely critical, the cam lobe is on the heel for half its diameter: http://www.engineprofessional.com/articles/EPQ215_62-66.pdf )

2) 13-12 = 1; set lash on valve# 1

3) Repeat#1 until valve# 11 is at rock, set lash on valve# 2

4) Repeat #1-2 for the remaining valves

1) Bump the starter until valve# 12 is at 'rock' (on the nose of the lobe) as close as possible, then put the car in 4th and move a front wheel, if necessary to get closer (it's not absolutely critical, the cam lobe is on the heel for half its diameter: http://www.engineprofessional.com/articles/EPQ215_62-66.pdf )

2) 13-12 = 1; set lash on valve# 1

3) Repeat#1 until valve# 11 is at rock, set lash on valve# 2

4) Repeat #1-2 for the remaining valves

red57

Jedi Knight

Offline

Bob is spot on and if you follow the sequence shown on this cheat-sheet, by doing them in this order, you can go thru all valves with the minimal turning of the engine (2 revolutions of the crank).

I have a plastic (nylon?) fan and after pulling the plugs, I do all my turning with the fan - pushing simultaneously on the belt with my thumb to keep it from slipping.

Dave

I have a plastic (nylon?) fan and after pulling the plugs, I do all my turning with the fan - pushing simultaneously on the belt with my thumb to keep it from slipping.

Dave

tahoe healey

Yoda

Offline

Less resistance if you remove the plugs.

Offline

I use the " no thought involved" method. Pull the plugs, turn the engine until you have a cylinder where you can wiggle both rockers ( i.e. you have some valve clearance on both which means you are on the heel and both valves are fully closed). Adjust both valve clearances. Since you know the firing order, turn until the next cylinder in order is on compression stroke and do those valves and so on until you are done. Sure there may be a bit more turning and if you watch, as soon as the rockers stop moving on a cylinder and the valves are closed, if you want TDC for OCD reasons you can put your thumb over the plug hole and turn until you get close to maximum compression.

If there is a reason for not doing it this way, I don't know what it is but we all have our favorite methods.

If there is a reason for not doing it this way, I don't know what it is but we all have our favorite methods.

Bob_Spidell

Yoda

Offline

I did it that way for years, but the 'Rule of 13' seems to give me more even clatter.

Not mentioned, yet, is the proper lash setting; the '0.12" Cold/Hot' on the valve cover may not apply to aftermarket cams (my DWR1 wants 0.015"). A previous aftermarket cam I had had different lash settings for exhaust and intake.

Not mentioned, yet, is the proper lash setting; the '0.12" Cold/Hot' on the valve cover may not apply to aftermarket cams (my DWR1 wants 0.015"). A previous aftermarket cam I had had different lash settings for exhaust and intake.

Offline

Yes, my DWR8 cam wants 0.015" also.

Offline

I like to use a paper timing disc divided into 1/6ths. Start with #1 at TDC on the compression stroke (both rockers loose) and plugs out. Set the disc to a mark on the distributor body, such as shown. Then rotate the fan or move the car in gear to go through the cylinders. I used a 30-60 triangle but circle-divided artwork is on Google.

Last edited:

Offline

I have used the EOIC formula in the past. Exhaust Opening, Intake Closing.

BJ8Healeys

Jedi Warrior

Offline

I have checked and adjusted my valves once a year before the driving season, after not checking them at all for 20 years and ending up with a burned valve about 20 years ago. My technique is to remove the radiator for access and use an open-end wrench on the dog nut to turn the engine (all plugs removed for easier turning). I found a wrench of the approximate size needed in an antique store, and filed the jaws a bit to make it fit the nut. Being an ex-engineer I tend to want to be as precise as possible. I have used a dial indicator when I had access to one. Not having one now, and following the "rule of 13", I turn the crank while watching the rocker arm nose go down until it can be seen to stop. This is "fully open" on that valve.

All good, but then I replaced the stock harmonic damper with a Pro/Race damper a couple years ago. It does not allow enough of the dog nut to protrude to use the wrench on it. I have a turning wrench made from a pipe and old timing belt than I plan to use as soon as I have the time to pull the radiator (I have a radiator shroud that prevents access with the radiator in place).

All good, but then I replaced the stock harmonic damper with a Pro/Race damper a couple years ago. It does not allow enough of the dog nut to protrude to use the wrench on it. I have a turning wrench made from a pipe and old timing belt than I plan to use as soon as I have the time to pull the radiator (I have a radiator shroud that prevents access with the radiator in place).

Offline

...My technique is to remove the radiator...

Removing the radiator sounds drastic!

When I had a generator, I used an offset box-end wrench that would fit the pulley nut. Pressing down on the fan belt, it was perfect for turning the engine over. With an alternator, now I have to put glove on and pull my fan blades.

Offline

My car is such that pulling the radiator is absolutely out of the question unless it leaks.

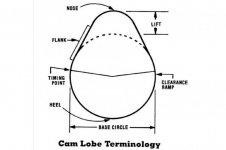

I use a remote starter switch. One thing to keep in mind is that when using the rule of 13, being precise about getting the one valve at it's maximum open position is not that necessary. The goal is to set the valve clearance when the lifter is on the base circle of the lobe. See this drawing:

The lifter is on the base circle for at least half of the lobe rotation.

The only time one needs to have the lifter absolutely on the nose of the lobe is when measuring lift.

Also, if you take the plugs out, put the car in gear and roll the car forward/backward to rotate the engine, it's easier to push on the top of a tire. That way, you get a little leverage.

I use a remote starter switch. One thing to keep in mind is that when using the rule of 13, being precise about getting the one valve at it's maximum open position is not that necessary. The goal is to set the valve clearance when the lifter is on the base circle of the lobe. See this drawing:

The lifter is on the base circle for at least half of the lobe rotation.

The only time one needs to have the lifter absolutely on the nose of the lobe is when measuring lift.

Also, if you take the plugs out, put the car in gear and roll the car forward/backward to rotate the engine, it's easier to push on the top of a tire. That way, you get a little leverage.

BJ8Healeys

Jedi Warrior

Offline

Removing the radiator sounds drastic!

I've done it enough that it only takes about 10 minutes after draining it -- loosen the two screws at the top and remove four screws at the bottom, pull out the bottom and loosen the lower hose clamp enough to slide the hose off the radiator nipple, take out the two top screws, and Bob's your uncle!

Bob_Spidell

Yoda

Offline

... My technique is to remove the radiator ...

YIKES!

... Being an ex-engineer ...

That explains it

YIKES!

... Being an ex-engineer ...

That explains it

BJ8Healeys

Jedi Warrior

Offline

Yuk, yuk!

I'm not recommending any specific technique, Bob, just describing how I do it and it works for me. I have tried the "roll the wheel"

method and found that I cannot move the car that way and still monitor the rockers as they move. As I mentioned, I have a radiator shroud that won't allow access to the dog nut with the radiator in place. Out of necessity, I began removing the radiator (heck, it's only once a year!) and I've gotten pretty good at it.

I'm not recommending any specific technique, Bob, just describing how I do it and it works for me. I have tried the "roll the wheel"

method and found that I cannot move the car that way and still monitor the rockers as they move. As I mentioned, I have a radiator shroud that won't allow access to the dog nut with the radiator in place. Out of necessity, I began removing the radiator (heck, it's only once a year!) and I've gotten pretty good at it.