-

Hi Guest!

Hi Guest!

If you appreciate British Car Forum and our 25 years of supporting British car enthusiasts with technical and anicdotal information, collected from our thousands of great members, please support us with a low-cost subscription. You can become a supporting member for less than the dues of most car clubs.

There are some perks with a member upgrade!**Upgrade Now**

(PS: Subscribers don't see this gawd-aweful banner

Tips

- We have a special forum called "Member Articles" where you can submit actual articles for consideration for publication. Learn More

- Don't have an Avatar? If not, your avatar will default to the 1st character in your username. Go into "Account Details" to change your Avatar.

- Some basic forum navigation info: click

Hey - did you know if you click on the title of a thread it will take you to the first unread post since you last visited that thread?

- Hey Guest - Is your British Car Club in our Clubs database? If not, send me a PM - Basil

- Looking for a local club? Click the "Clubs" tab above and browse hundreds of clubs world-wide.

- Add Android or iPhone APP: click

- Did you know - any picture or video you add in your posts in any marque-specific forum will also get added to the Media Gallery automatically.

- A few more tips about posting and replying: click

- Hey there Guest - be sure to keep your profile page up to date with interesting info about yourself: learn more

- More tips and tricks on Posting and Replying: click

STOP!! Never post your email address in open forums. Bots can "harvest" your email! If you must share your email use a Private Message or use the

STOP!! Never post your email address in open forums. Bots can "harvest" your email! If you must share your email use a Private Message or use the  smilie in place of the real @

smilie in place of the real @

- Want to mention another member in a post & get their attention? WATCH THIS

- So, you created a "Group" here at BCF and would like to invite other members to join? Watch this!

- Hey Guest - A post a day keeps Basil from visiting you in the small hours and putting a bat up your nightdress!

- Hey Guest - do you know of an upcoming British car event?

Pretty Please - add it to our Events forum(s) and add to the calendar! >> Here's How <<

Pretty Please - add it to our Events forum(s) and add to the calendar! >> Here's How <<

- Hey Guest - you be stylin'

Change the look and feel of the forum to fit your taste. Check it out

- If you run across an inappropriate post, for example a post that breaks our rules or looks like it might be spam, you can report the post to the moderators: Learn More

- If you would like to try some different "looks" or styles for the site, scroll to the very bottom, on the left and click the Style Selector.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

TR2/3/3A TR6 gearbox on TR3: re clutch slave adjustment.

- Thread starter karls59tr

- Start date

TR3driver

Great Pumpkin - R.I.P

Offline

Yes. There are several possible solutions; what I did was fabricate a slightly shorter pushrod and a tab to keep the spring length roughly the same. Another option is to beat the flywheel cover flat in that area, and move the slave mount to the other side of the flanges on both the transmission and the slave (which is the way the TR6 does it).

Marvin Gruber

Yoda

Offline

Don't think there's enough thickness to effect the slave cylinder and length of rod. Try it first and see. Another solution is make the rod a little longer. I have done what Randall suggests, that will work as will. Still say try original set up first and see.

Marv

Marv

TR3driver

Great Pumpkin - R.I.P

Offline

Might well depend on which version of TR6 gearbox you get. I'm running a later box (CC prefix), specifically because it has the flange & ribs beefed up. In my case, there was no question of not doing something to make it fit; the pushrod was still holding the clutch depressed even with the pushrod touching the lever. But it certainly won't hurt to try.

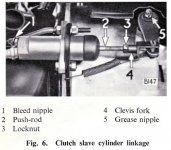

Here's the best shot of the TR6 setup I could find on short notice. On the TR3, the bracket mounts to the rear side of the gearbox flange and then the slave mounts to the front of the bracket. On the TR6, it's the other way around, the bracket mounts to the front of the gearbox flange and the slave mounts to the back of the bracket.

I didn't want to ruin my original pushrod, so I just made up a new one. Ordinary mild steel rod from the hardware store, same diameter as original (5/16" I think, but that was a long time ago). Fine threads up one end, then the other end rounded (more or less) by hand with a grinder. But you could achieve the same effect with the original. Replacements are readily available now.

The length of the return spring is kind of important, it needs to have enough tension to always pull the slave cylinder piston all the way home after every clutch use. If not, the point in the pedal travel where the clutch engages will drift up and down. Might not bother some folks, but it really bugs me. (Geo will probably be along in a bit and tell us he doesn't use a return spring, so evidently it doesn't bug him.) But, since the spring runs between the bracket and the clevis, and the bracket is moving closer to the clevis, the spring may not have enough tension to always pull the piston back. I'm actually running that way at the moment, as I neglected to move the tab over when I moved Frankenbox from the wrecked TR3A into my current TR3. And it still bugs me, just not enough for me to actually crawl back under there and fix it (yet).

The tab I made is just a short section of flat iron (again from Home Depot). From memory, about 1/2" wide, 1/8" thick and maybe 3/4" long or a bit longer. It doesn't need to be that thick, it's just what I had on hand. 5/16" hole centered about 1/2" from one end for the mounting bolt, then a 1/8" hole near a corner on the other end. And a bit of a bend in the middle, maybe 30 degrees or so, because it didn't add quite enough when it was flat.

Here's the best shot of the TR6 setup I could find on short notice. On the TR3, the bracket mounts to the rear side of the gearbox flange and then the slave mounts to the front of the bracket. On the TR6, it's the other way around, the bracket mounts to the front of the gearbox flange and the slave mounts to the back of the bracket.

I didn't want to ruin my original pushrod, so I just made up a new one. Ordinary mild steel rod from the hardware store, same diameter as original (5/16" I think, but that was a long time ago). Fine threads up one end, then the other end rounded (more or less) by hand with a grinder. But you could achieve the same effect with the original. Replacements are readily available now.

The length of the return spring is kind of important, it needs to have enough tension to always pull the slave cylinder piston all the way home after every clutch use. If not, the point in the pedal travel where the clutch engages will drift up and down. Might not bother some folks, but it really bugs me. (Geo will probably be along in a bit and tell us he doesn't use a return spring, so evidently it doesn't bug him.) But, since the spring runs between the bracket and the clevis, and the bracket is moving closer to the clevis, the spring may not have enough tension to always pull the piston back. I'm actually running that way at the moment, as I neglected to move the tab over when I moved Frankenbox from the wrecked TR3A into my current TR3. And it still bugs me, just not enough for me to actually crawl back under there and fix it (yet).

The tab I made is just a short section of flat iron (again from Home Depot). From memory, about 1/2" wide, 1/8" thick and maybe 3/4" long or a bit longer. It doesn't need to be that thick, it's just what I had on hand. 5/16" hole centered about 1/2" from one end for the mounting bolt, then a 1/8" hole near a corner on the other end. And a bit of a bend in the middle, maybe 30 degrees or so, because it didn't add quite enough when it was flat.

TR3driver

Great Pumpkin - R.I.P

Offline

In my case, I had to make the pushrod shorter. Maybe he is talking about the other setup, where you move the bracket in front of the gearbox flange.Thanks for the info Randall.....Did you make the pushrod shorter?..... or longer as Marvin suggested?

Here's a shot of the old tab. It's closer to 3/16" thick (but again was just what I had on hand at the time, even 3/32 would be plenty thick).

Randall In this picture it appears that the slave is mounted to the front of the bracket but in the TR6 pic the slave is mounted to the rear of the bracket? for the modification did you mean that the bracket is to be mounted to the "rear" of the gearbox flange and the slave is to be mounted to the " front" of the bracket.

If I try this setup the stay rod that attaches to the oil pan bolt would run out of the threaded part of the rod at the attachment nut at the slave?in other words I'd have to thread a few more inches of the rod for the top slave to bracket mounting point. is this what you did?

I tried the stock TR3 setup but it seems the clutch is not disengaging so I'm going to try your method. How can I determine how long the pushrod should be...that is how much to take off?

It also looks like the pushrod would run more parallel with the slave if the 2nd hole on the cross shaft lever was used rather than the bottom.

If I try this setup the stay rod that attaches to the oil pan bolt would run out of the threaded part of the rod at the attachment nut at the slave?in other words I'd have to thread a few more inches of the rod for the top slave to bracket mounting point. is this what you did?

I tried the stock TR3 setup but it seems the clutch is not disengaging so I'm going to try your method. How can I determine how long the pushrod should be...that is how much to take off?

It also looks like the pushrod would run more parallel with the slave if the 2nd hole on the cross shaft lever was used rather than the bottom.

TR3driver

Great Pumpkin - R.I.P

Offline

Randall In this picture it appears that the slave is mounted to the front of the bracket but in the TR6 pic the slave is mounted to the rear of the bracket?

Let me try this again. There are two approaches to this problem. One approach is to use the TR6 style slave mounting. I didn't do that; instead I used the TR3 style mounting. You will have to pick which way you want to go.

For the TR6 style, the bracket mounts to the front of the gearbox flange (near the engine), and the slave mounts to the back of the bracket. But on a TR3, there is a cover on the front of the flange, which has a rolled edge. To do this on a TR3, you'll have to either beat that rolled edge flat, or leave the cover off. I don't know what other implications there are, but it is quite possible that you'll need to modify the stay rod and/or pushrod for this approach.

For the TR3 style, the bracket mounts to the back of the gearbox flange, and the slave mounts to the front of the bracket. If you look closely at the photo at https://goo.gl/wYJvl, perhaps you can see the bracket and slave down in the corner. For me anyway, the stay rod had plenty of threads to accommodate the change. As I outlined before, I made a shorter pushrod, and the tab shown above to stretch the return spring a bit more. The tab is definitely optional, so don't worry about that if you don't want to. (I've been driving without it since 2008.) You need to shorten the rod enough to achieve the correct adjustment. What I did was to install the clevis onto the lever (center hole, as you noted), then hold the pushrod up to it with the piston bottomed in the slave and the lever as far back as it would go. The overlap between the rod & lever is how much to remove from the rod (since obviously the rod has to not touch the lever).

TR3driver

Great Pumpkin - R.I.P

Offline

I'm sure there is, but I don't know what it is. The service manual just says to compare them to new ones.While were on the clutch subject.....is there a method to test the pressure plate springs?...

For the TR3 style, the bracket mounts to the back of the gearbox flange, and the slave mounts to the front of the bracket.

If I may, I'd like to add a related question to this discussion. I too am in the process of trying to adjust the clutch slave after both the brake and clutch hydraulics were restored. I've read many of the threads on this topic (some twice or more) and have not been successful in getting the clutch to work properly. Your posts in the thread "Position/Adjustment of TR3A Clutch Slave Cylinder" were very helpful. Especially the photo of the linkage. I'll repost it here since it will illustrate what I now think my problem may be.

Using this configuration, I can back the rod almost completely out of the fork and it seems that the piston is no where near bottomed out. As a result I'm barely able to disengage the clutch, if at all. After hours of fiddling it occurred to me that I may not have the right push rod. This slave was installed by someone else that was doing some work on the car at the time, so I don't really know the origin of the rod. This rod is just under three inches long. From the photo you posted, and several others that I've seen, it looks like the appropriate push rod has got to be a good bit longer than three inches in order to get a full range of movement of the slave piston.

Randall, would or any one else have any specs on what might be considered a "standard" push rod? I should add that mine is a TR-4 transmission on a stock TR-3A engine. Bracket is on the back of the bell housing and the slave is mounted on the forward side of the bracket, away from the lever.

Rick...

Yeah, that's definitely way too short. I just checked an original from the used parts bin, and it is nearly 4-1/2" (closer to 4-7/16" perhaps, I didn't measure closely). (Measured as you showed, without the clevis.)

I'll bet that's the problem then. I'll put one on order this morning. Moss has them listed.

Rick...