SteveBones

Jedi Trainee

Offline

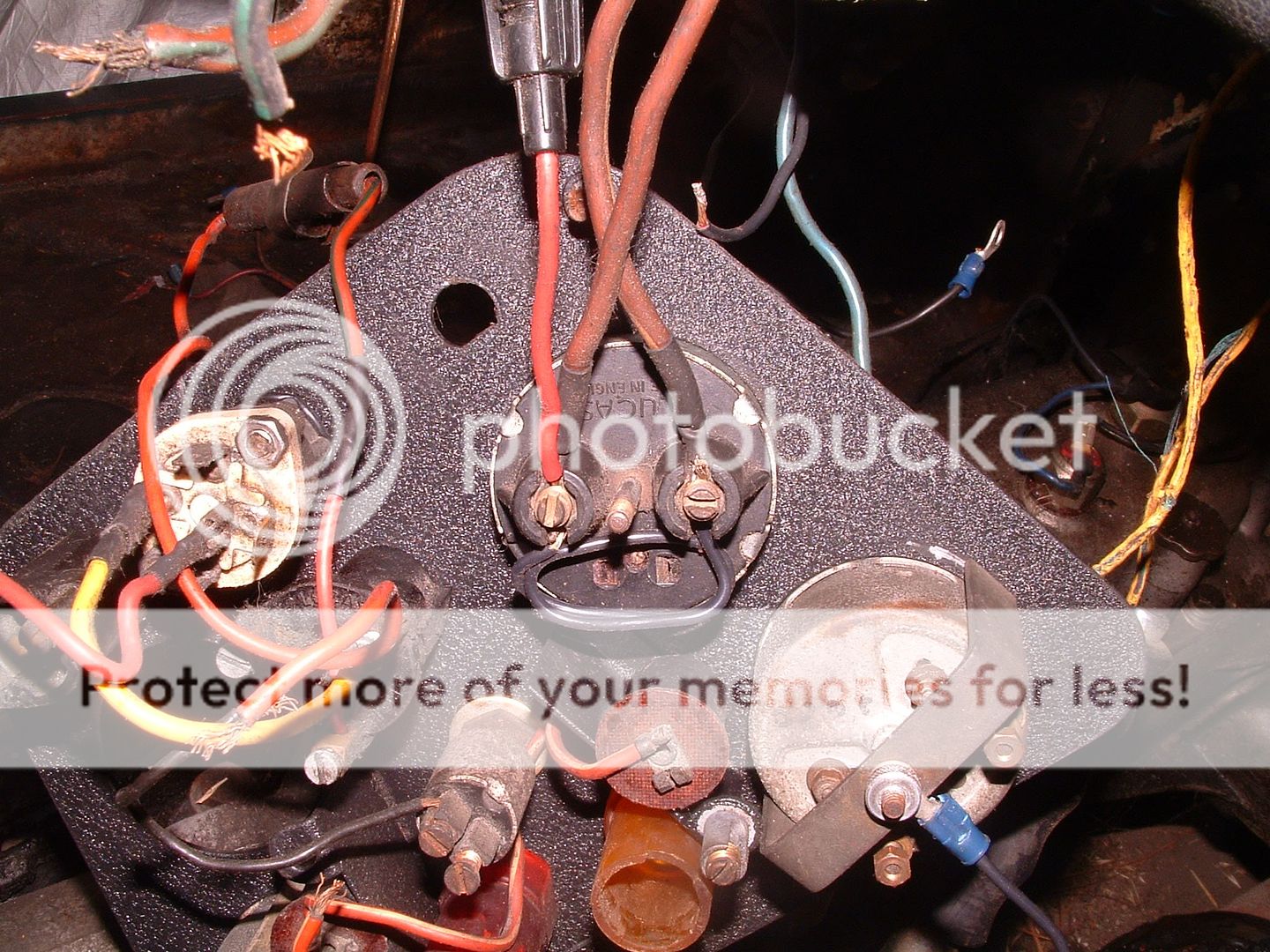

I am in the process of rebuilding my wiper motor. I wanted to check and see if there is anything I should be looking for during the process.

Reason Why I am Rebuilding

--------------------------------

1) Was not working until it did starting working briefly today. Prior when I pulled the wiper switch, I would see approx 20 amp current draw on the amp meter without any movement from the wiper. When the wiper briefly started working today, it stopped before parking. Even when I pushed the wiper switch "closed", I was still drawing the 20 amps of current. I went to disconnect the wires at the wiper motor and notice the wiper motor was very warm.

2) After taking the wiper motor apart, I cleaned the armature communicator (sp?) with emery cloth so should be good to go.

3) The brushes are worn down to where the spring loaded arm where the brushes fit is just starting to make contact with the communicator. I believe this is why the wiper is not working but drawing 20 amps of current.

4) The wiper mechanism itself is working well without binding when the motor is disconnected and I manually move the wipers.

What I plan to do?

---------------------

At this point I will only replacing the brushes. I wanted to check and see if there is anything else I should do while the wiper motor is out of the car. The wiper motor gear is well greased by the PO so good to go here.

Thanks,

Steve

Reason Why I am Rebuilding

--------------------------------

1) Was not working until it did starting working briefly today. Prior when I pulled the wiper switch, I would see approx 20 amp current draw on the amp meter without any movement from the wiper. When the wiper briefly started working today, it stopped before parking. Even when I pushed the wiper switch "closed", I was still drawing the 20 amps of current. I went to disconnect the wires at the wiper motor and notice the wiper motor was very warm.

2) After taking the wiper motor apart, I cleaned the armature communicator (sp?) with emery cloth so should be good to go.

3) The brushes are worn down to where the spring loaded arm where the brushes fit is just starting to make contact with the communicator. I believe this is why the wiper is not working but drawing 20 amps of current.

4) The wiper mechanism itself is working well without binding when the motor is disconnected and I manually move the wipers.

What I plan to do?

---------------------

At this point I will only replacing the brushes. I wanted to check and see if there is anything else I should do while the wiper motor is out of the car. The wiper motor gear is well greased by the PO so good to go here.

Thanks,

Steve

Hi Guest!

Hi Guest!

smilie in place of the real @

smilie in place of the real @

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

Pretty Please - add it to our Events forum(s) and add to the calendar! >>