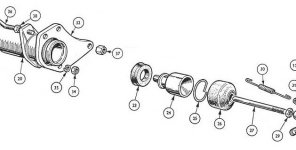

I am installing a nos slave cylinder ,supposed to be for tr3, and have a few questions

The clevis I have is ,I think, the right one with weired screw pin and spring washer and bracket for return spring.

All three holes in clutch shaft lever are about 1/4",but center of pin is about 5/16,stepped to 1/4 for the end and cotter pin.I think I just have to drill it out in place ,but am wondering whats wrong-later clevis assembly-early lever?

Also on adjustment I read an old post by Randall

(I hope your out there)on Triumph forum that the slave cylinder should have external spring to force piston to bottom of bore even if rod is absent.My cyinder is as shown in Clymer Owners Handbook for t2-4,internal filler cup spring and lever return spring.

I think can adjust rod length for the required freeplay with plunger at bottom of bore with system dry,but was also wondering if piston can over extend,bending rod or lever,especially when adjustment procedure mentioned starting by measuring lever travel,which I havent done.

Your thoughts and info much appreciated,

Tom

The clevis I have is ,I think, the right one with weired screw pin and spring washer and bracket for return spring.

All three holes in clutch shaft lever are about 1/4",but center of pin is about 5/16,stepped to 1/4 for the end and cotter pin.I think I just have to drill it out in place ,but am wondering whats wrong-later clevis assembly-early lever?

Also on adjustment I read an old post by Randall

(I hope your out there)on Triumph forum that the slave cylinder should have external spring to force piston to bottom of bore even if rod is absent.My cyinder is as shown in Clymer Owners Handbook for t2-4,internal filler cup spring and lever return spring.

I think can adjust rod length for the required freeplay with plunger at bottom of bore with system dry,but was also wondering if piston can over extend,bending rod or lever,especially when adjustment procedure mentioned starting by measuring lever travel,which I havent done.

Your thoughts and info much appreciated,

Tom

Hi Guest!

Hi Guest!

smilie in place of the real @

smilie in place of the real @

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

Pretty Please - add it to our Events forum(s) and add to the calendar! >>