I am deleting the bumpers on my 77 Midget and needed the tail light extensions to make it look somewhat passable. I'm pleased with the result so I thought I'd share the process.

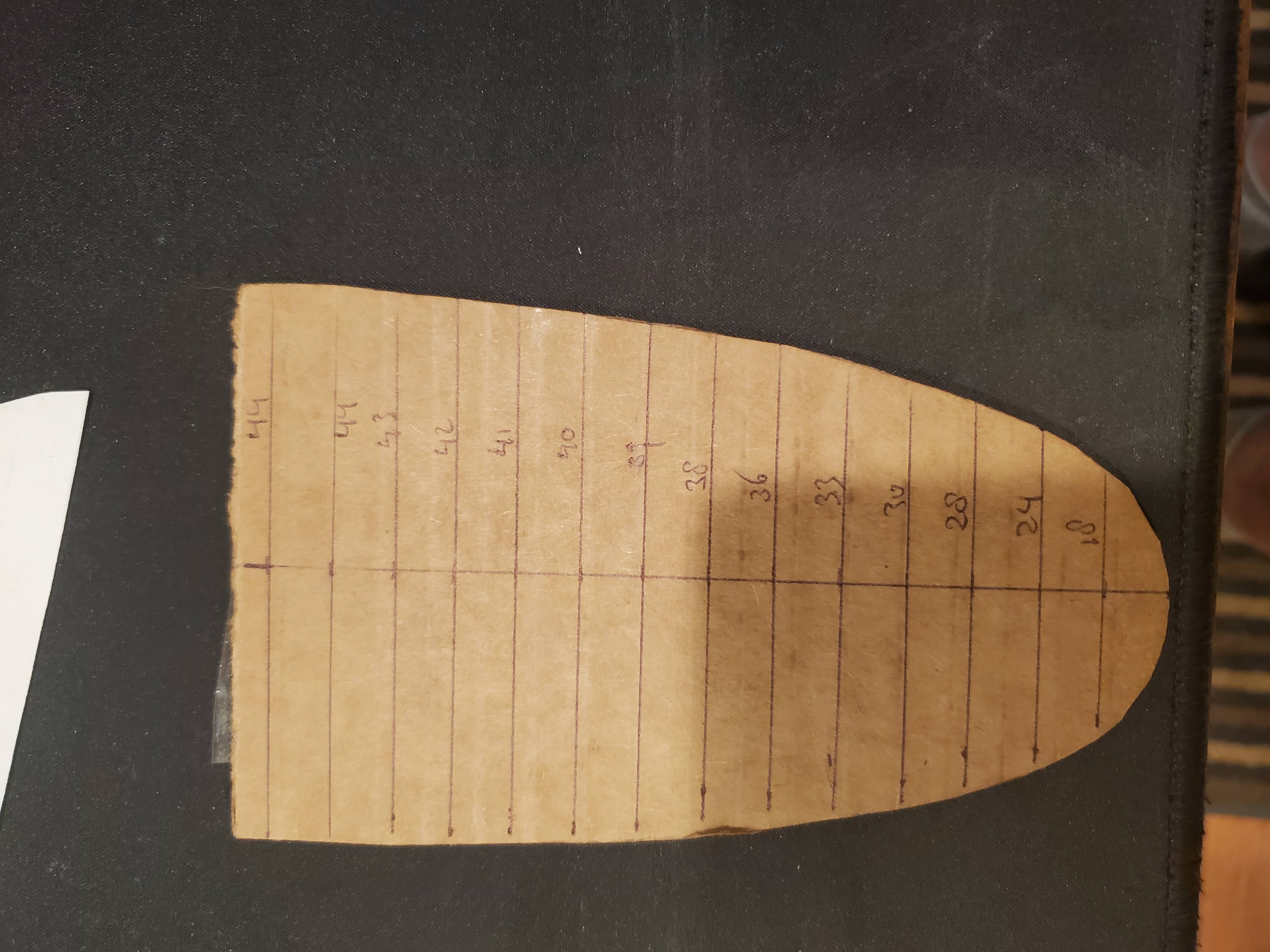

I first made a cardboard template of the flat base on the car. I added some measurements in mm to transfer in to autocad fusion.

I also took some measurements under the tail light to approximate the curve.

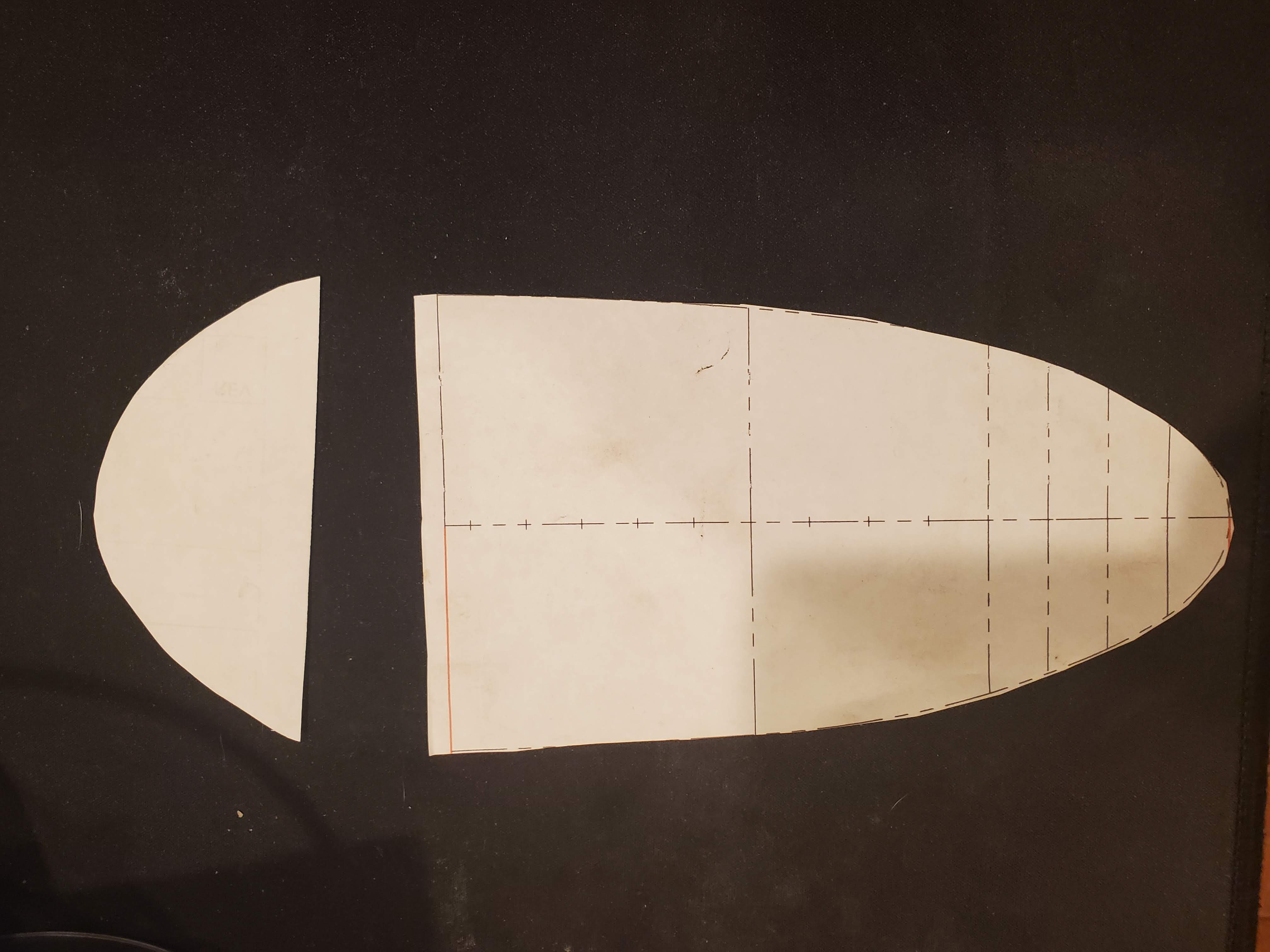

After transfering in to fusion360 I printed out to scale and cut it out to verify back on the car.

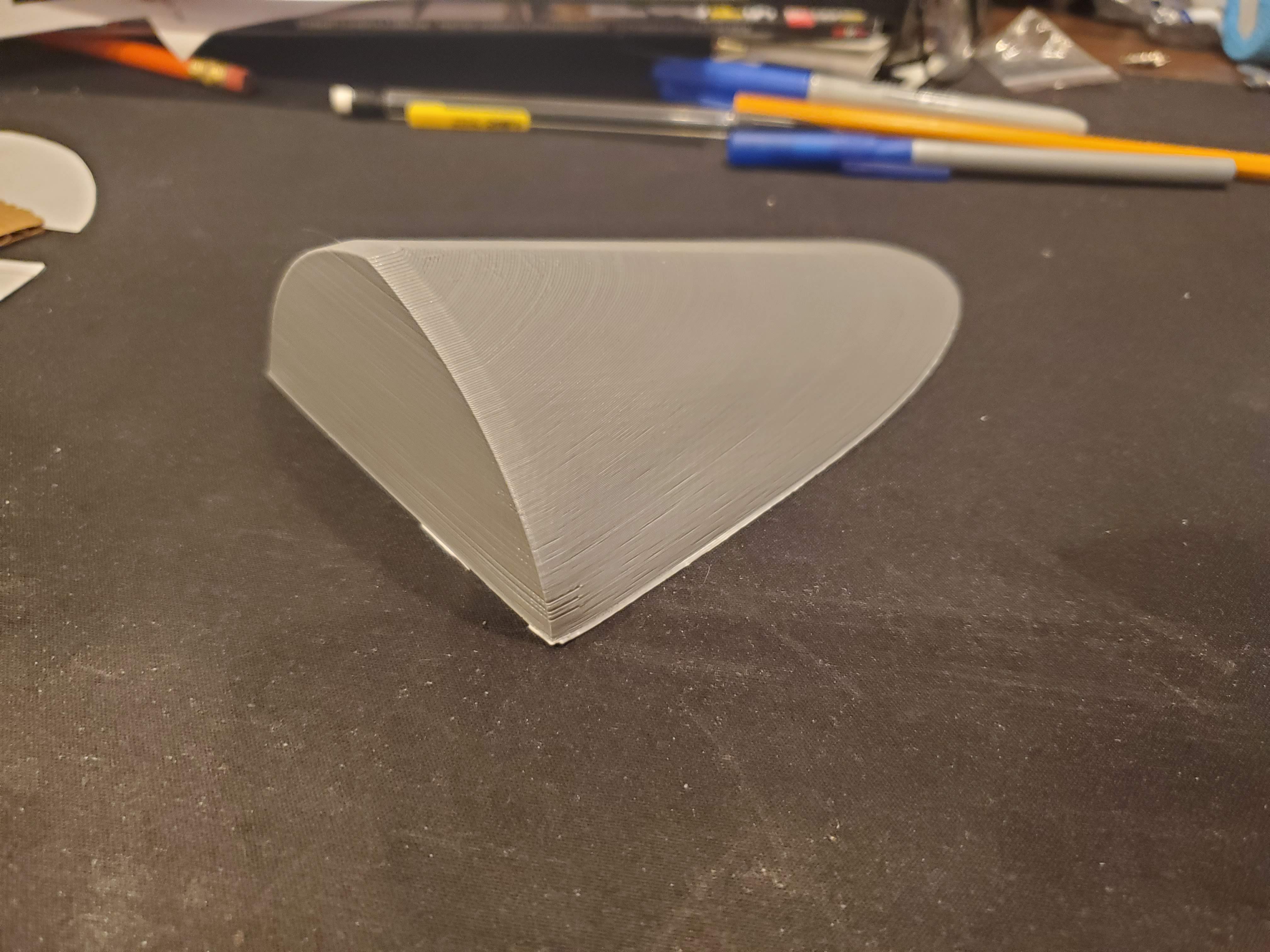

With the measurements verified I used fusion360's loft function to create a 3D model.

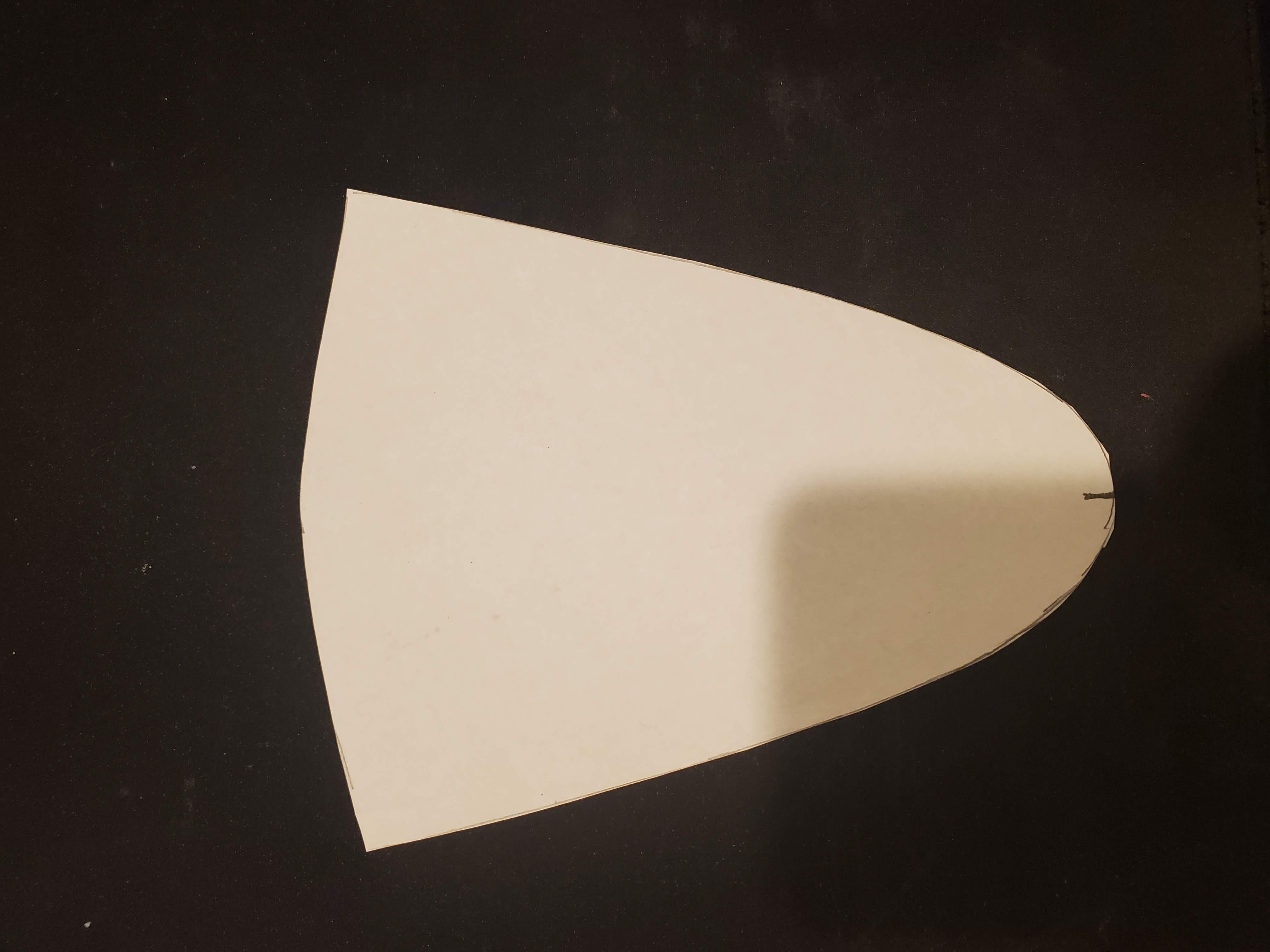

When I put it in place it looked pretty good and I thought that I would use fiberglass to put it in place and printed a second one. As I was playing around with it I realised I could use the 3D model to make a flat model by rolling it on paper and tracing it as it rolls.

When I cut it out it perfectly wrapped the 3D model so I did the same thing with 18 gauge steel and used a slip roll to bend it. I'm sure one could manage to bend it over a steel pipe as well.

I still have to make the second one and weld them in place

I have included a scan of the unrolled surface as an PDF file with this article. It may come in handy for someone else to use.

Good luck,

Reinder

I first made a cardboard template of the flat base on the car. I added some measurements in mm to transfer in to autocad fusion.

I also took some measurements under the tail light to approximate the curve.

After transfering in to fusion360 I printed out to scale and cut it out to verify back on the car.

With the measurements verified I used fusion360's loft function to create a 3D model.

When I put it in place it looked pretty good and I thought that I would use fiberglass to put it in place and printed a second one. As I was playing around with it I realised I could use the 3D model to make a flat model by rolling it on paper and tracing it as it rolls.

When I cut it out it perfectly wrapped the 3D model so I did the same thing with 18 gauge steel and used a slip roll to bend it. I'm sure one could manage to bend it over a steel pipe as well.

I still have to make the second one and weld them in place

I have included a scan of the unrolled surface as an PDF file with this article. It may come in handy for someone else to use.

Good luck,

Reinder

Hi Guest!

Hi Guest!

smilie in place of the real @

smilie in place of the real @

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

Pretty Please - add it to our Events forum(s) and add to the calendar! >>