bob hughes

Luke Skywalker

Offline

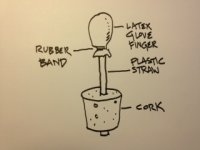

I am sure that I saw a reference to static timing with a lamp recently but can not find it. When I was a lad far too many years ago, we used to set the timing on a mini using a small head lamp bulb in a holder and wired it up to the dizzy, set the crankshaft to the correct point - TDC I think, and then turned the dizzy until the light just came on for number one cylinder - points just opening. For the life of me I can not remember where the wires from the light went - I think that one was on the low tension circuit on the side of the dizzy and the other on one side of the points?? Can the Great Ensemble assist please.

Panic over, the grey matter has finally clicked in - the other lead goes to ground

Bob

Panic over, the grey matter has finally clicked in - the other lead goes to ground

Bob

Hi Guest!

Hi Guest!

smilie in place of the real @

smilie in place of the real @

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

Pretty Please - add it to our Events forum(s) and add to the calendar! >>