AUSMHLY

Yoda

Offline

Seems I have a squeak coming both sides, rear of my BJ8. Sounds like a rubber type squeak.

Noticed it when driving.

When stationary, pushing on the rear wings, something squeaks when traveling up and down.

No squeak when pushing on the front wings.

Front and back shocks seems to be doing their job. After one push, car comes back up and stops with a little movement after.

. Do shocks squeak when going bad?

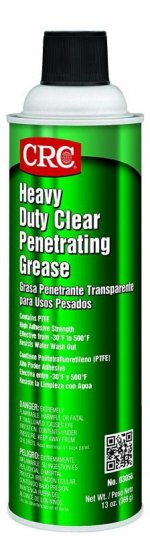

. Gut feeling is squeak is related to the leaf springs. Any type of lubrication I can spray them with?

. Some other area I need to look into?

Thanks guys

Noticed it when driving.

When stationary, pushing on the rear wings, something squeaks when traveling up and down.

No squeak when pushing on the front wings.

Front and back shocks seems to be doing their job. After one push, car comes back up and stops with a little movement after.

. Do shocks squeak when going bad?

. Gut feeling is squeak is related to the leaf springs. Any type of lubrication I can spray them with?

. Some other area I need to look into?

Thanks guys

Hi Guest!

Hi Guest!

smilie in place of the real @

smilie in place of the real @

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

Pretty Please - add it to our Events forum(s) and add to the calendar! >>