-

Hi Guest!

Hi Guest!

If you appreciate British Car Forum and our 25 years of supporting British car enthusiasts with technical and anicdotal information, collected from our thousands of great members, please support us with a low-cost subscription. You can become a supporting member for less than the dues of most car clubs.

There are some perks with a member upgrade!**Upgrade Now**

(PS: Subscribers don't see this gawd-aweful banner

Tips

- We have a special forum called "Member Articles" where you can submit actual articles for consideration for publication. Learn More

- Don't have an Avatar? If not, your avatar will default to the 1st character in your username. Go into "Account Details" to change your Avatar.

- Some basic forum navigation info: click

Hey - did you know if you click on the title of a thread it will take you to the first unread post since you last visited that thread?

- Hey Guest - Is your British Car Club in our Clubs database? If not, send me a PM - Basil

- Looking for a local club? Click the "Clubs" tab above and browse hundreds of clubs world-wide.

- Add Android or iPhone APP: click

- Did you know - any picture or video you add in your posts in any marque-specific forum will also get added to the Media Gallery automatically.

- A few more tips about posting and replying: click

- Hey there Guest - be sure to keep your profile page up to date with interesting info about yourself: learn more

- More tips and tricks on Posting and Replying: click

STOP!! Never post your email address in open forums. Bots can "harvest" your email! If you must share your email use a Private Message or use the

STOP!! Never post your email address in open forums. Bots can "harvest" your email! If you must share your email use a Private Message or use the  smilie in place of the real @

smilie in place of the real @

- Want to mention another member in a post & get their attention? WATCH THIS

- So, you created a "Group" here at BCF and would like to invite other members to join? Watch this!

- Hey Guest - A post a day keeps Basil from visiting you in the small hours and putting a bat up your nightdress!

- Hey Guest - do you know of an upcoming British car event?

Pretty Please - add it to our Events forum(s) and add to the calendar! >> Here's How <<

Pretty Please - add it to our Events forum(s) and add to the calendar! >> Here's How <<

- Hey Guest - you be stylin'

Change the look and feel of the forum to fit your taste. Check it out

- If you run across an inappropriate post, for example a post that breaks our rules or looks like it might be spam, you can report the post to the moderators: Learn More

- If you would like to try some different "looks" or styles for the site, scroll to the very bottom, on the left and click the Style Selector.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Sprite Twin Tone Horns

- Thread starter bjoebill

- Start date

Offline

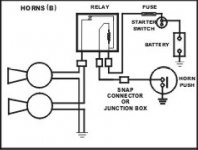

Yes, you definitely need a relay. The wiring diagram in the shop manual shows how to wire them, and it shows the relay as well. This diagram can be found in the Haynes manual too. The horns themselves are simply wired in parallel; the relay switches them in the usual fashion.

I'm away from my office now, but if you need more info let me know and I'll scan the wiring diagram. Every Sprite owner should have a copy...!

I'm away from my office now, but if you need more info let me know and I'll scan the wiring diagram. Every Sprite owner should have a copy...!

tosoutherncars

Jedi Knight

Offline

I bought a generic set of horns, and it came with a relay and wiring instructions.

Offline

spritenut said:I put twin horns on my 67. I just added wires from the first horn to the second.

It works, no relays.

I don't doubt it will work for a while, but I suspect you will fry the contacts in the horn button or steering brush eventually. Those little suckers pull a lot of current (stock ones are ~12A peak, ~6A average, EACH), and the fact that they are an inductive load will cause quite a bit more sparking at the contacts than normal. I'd really recommend putting in a relay--cheap and simple.

tony barnhill

Great Pumpkin - R.I.P

Offline

I'm curious...

I researched horns when I was at that point in my '63 Midget restoration....the 2nd horn was a factory option, they all came from the factory with 1 horn unless specified.

The wiring diagram didn't show any difference between the single & dual horn setup other than the wires between the 2 horns.

So, I ordered a set of new horn brackets, a set of new horns & made a wiring harness from one horn to the other out of the correct guage & color wiring.....& hooked it up.

Why won't it work?

I researched horns when I was at that point in my '63 Midget restoration....the 2nd horn was a factory option, they all came from the factory with 1 horn unless specified.

The wiring diagram didn't show any difference between the single & dual horn setup other than the wires between the 2 horns.

So, I ordered a set of new horn brackets, a set of new horns & made a wiring harness from one horn to the other out of the correct guage & color wiring.....& hooked it up.

Why won't it work?

tosoutherncars

Jedi Knight

Offline

As stock, the full amperage goes through the switch, which eventually causes it to fail. It'll fail even faster, with double the current.

So, as with uprated headlights, electric fans, electric fuel pumps and anything else that pulls a lot of power, a relay can be used to minimize the current carried by the horn switch contacts, and to reduce voltage drop.

Not totally necessary... just a little extra protection.

So, as with uprated headlights, electric fans, electric fuel pumps and anything else that pulls a lot of power, a relay can be used to minimize the current carried by the horn switch contacts, and to reduce voltage drop.

Not totally necessary... just a little extra protection.

Attachments

tony barnhill

Great Pumpkin - R.I.P

Offline

So, why do all my MG dual horn set-ups still work 30 years after the factory closed? Don't see relays in the wiring harnesses

tosoutherncars

Jedi Knight

Offline

Maybe you've been keeping them in shape by using them regularly? :wink: Seriously though, I thought it was a pretty common failure. Didn't Jack have to redo the horn contacts on Miss Agatha?

BugEyeBear

Jedi Trainee

Offline

tony barnhill said:So, why do all my MG dual horn set-ups still work 30 years after the factory closed? Don't see relays in the wiring harnesses

Tony,

Although I tend to agree with you on your comment, I'm not so sure I'd EVER trust the judgement of anything associated with an installation that incorporates ANYTHING LUCAS!!

They didn't earn the "Prince Of Darkness" nickname because of their reputation for reliability!! :eeek:

I think I'd put a relay in JUST TO BE SAFE! That and some additional fuses, some fusable links, and a generous supply of wire, fuses, elect tape, and a Fire Extinguisher in the trunk!!

"Better safe than stuck on the side of the road...."

"Cheers!"

-Bear-

tony barnhill

Great Pumpkin - R.I.P

Offline

See, whenever I have the rare Lucas flare-up, it can be traced to poor maintenance...usually, its a corroded connector or ground...occasssionally, an instrument will finally - after 30 years - fail....but, Lucas problems? No, not on a properly maintained car....& I 'll bet the horn system just like everything else was over-designed at the factory.

Remember, I'm the guy who took off across the US, Canada, & Alaska in my RV on a 15,000, 6-month trip with only my '79 MGB for daily transportation....true, I'm its only owner & have done all my maintenance on it religiously.....the only thing that failed was the OE air pump that I forgot to do maintenance on before we left...I'm still convinced that, had I sprayed white lithium grease up inside it before we left, it would still be working!

I'm not gonna worry about my horns.

Remember, I'm the guy who took off across the US, Canada, & Alaska in my RV on a 15,000, 6-month trip with only my '79 MGB for daily transportation....true, I'm its only owner & have done all my maintenance on it religiously.....the only thing that failed was the OE air pump that I forgot to do maintenance on before we left...I'm still convinced that, had I sprayed white lithium grease up inside it before we left, it would still be working!

I'm not gonna worry about my horns.

BugEyeBear

Jedi Trainee

Offline

Hi Tony,

I agree that I wouldn't worry about your factory installation. I TOO tend to leave things alone that haven't been tinkered with. (My '60 BugEye, '47 Austin10, & '57 Austin FX3 Taxicab are all 100% stock!)

"If it ain't broken don't FIX it!!"

BUT whenever I get in there & modify anything I try to upgrade it to a better quality installation that originally designed.

I have to admit that I've had pretty good luck w my Lucas electrics. Haven't really had reason to complain to date.... (Wait! Where's some WOOD?!? Quick!!)

BUT I do tend to be a bit of a "Worry Wart", so anything I can do to safeguard an installation simply provides me with a better night's sleep.

Simply put, if someone asks me how to do it, I'd have to recommend spending a few extra $$$ up front and do an extra safe installation. I'd hate to make a recommendation that might fail them at a later date. Besides, it is cheap insurance that'll pay for itself with the 1st missed tow truck call!

"Cheers!"

-Bear-

I agree that I wouldn't worry about your factory installation. I TOO tend to leave things alone that haven't been tinkered with. (My '60 BugEye, '47 Austin10, & '57 Austin FX3 Taxicab are all 100% stock!)

"If it ain't broken don't FIX it!!"

BUT whenever I get in there & modify anything I try to upgrade it to a better quality installation that originally designed.

I have to admit that I've had pretty good luck w my Lucas electrics. Haven't really had reason to complain to date.... (Wait! Where's some WOOD?!? Quick!!)

BUT I do tend to be a bit of a "Worry Wart", so anything I can do to safeguard an installation simply provides me with a better night's sleep.

Simply put, if someone asks me how to do it, I'd have to recommend spending a few extra $$$ up front and do an extra safe installation. I'd hate to make a recommendation that might fail them at a later date. Besides, it is cheap insurance that'll pay for itself with the 1st missed tow truck call!

"Cheers!"

-Bear-

I have installed dual horns, and/or air horns with out ever using a relay.

Sure it's a good thing but the factory never did it. and twin wind tone horns were optional on most Brit cars back in the day. They just added a wire jumper from one to the other.

I never had a failure and I have been driving a Sprite for 36 years.

Sure it's a good thing but the factory never did it. and twin wind tone horns were optional on most Brit cars back in the day. They just added a wire jumper from one to the other.

I never had a failure and I have been driving a Sprite for 36 years.

Offline

The simple answer to Tony's question is (and this is my suspicion; I have no hard information) that the MGB horn buttons were probably designed to handle the current. It's also possible that Lucas got sensible at some point and created a horn that didn't require half the output of the Hoover dam to run it. I see no reason why a car horn should require more than a couple amps, but the original Spridget ones surely did.

tony barnhill

Great Pumpkin - R.I.P

Offline

So, does anybody know where to factory would've put the relay?

& which Lucas relay it was?

& which Lucas relay it was?