well...I finally broke down and yanked the distributor out of the car last night (Delco D204)because I noticed a scraping noise coming from it and I also noticed that the rotor seemed to be firing from the top of the tab, not the end. I have multiple questions that are posted after the pics.

my questions are:

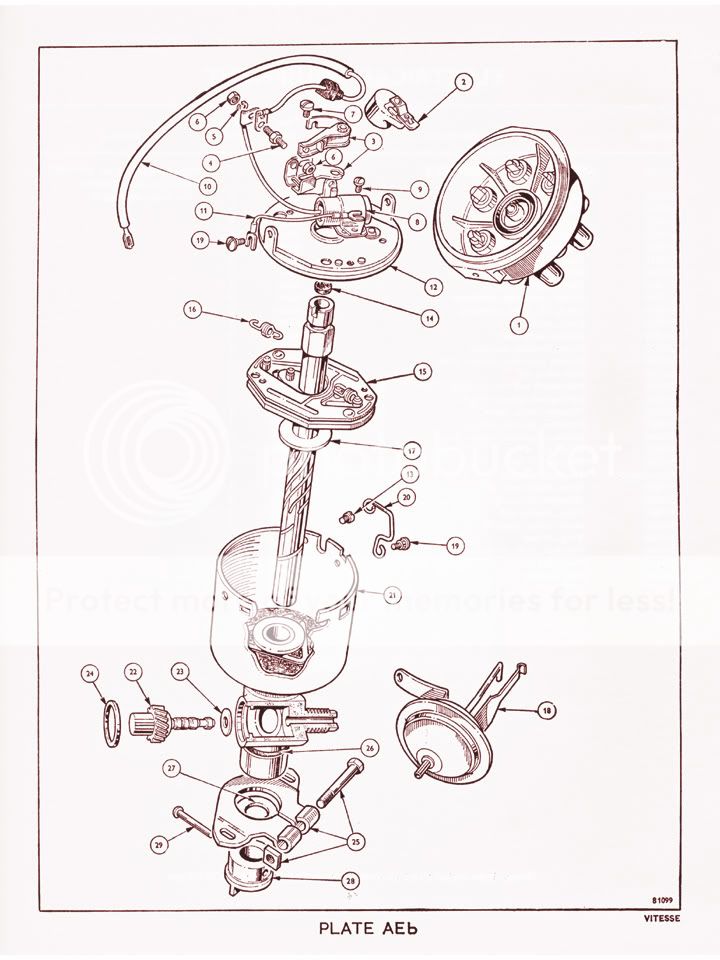

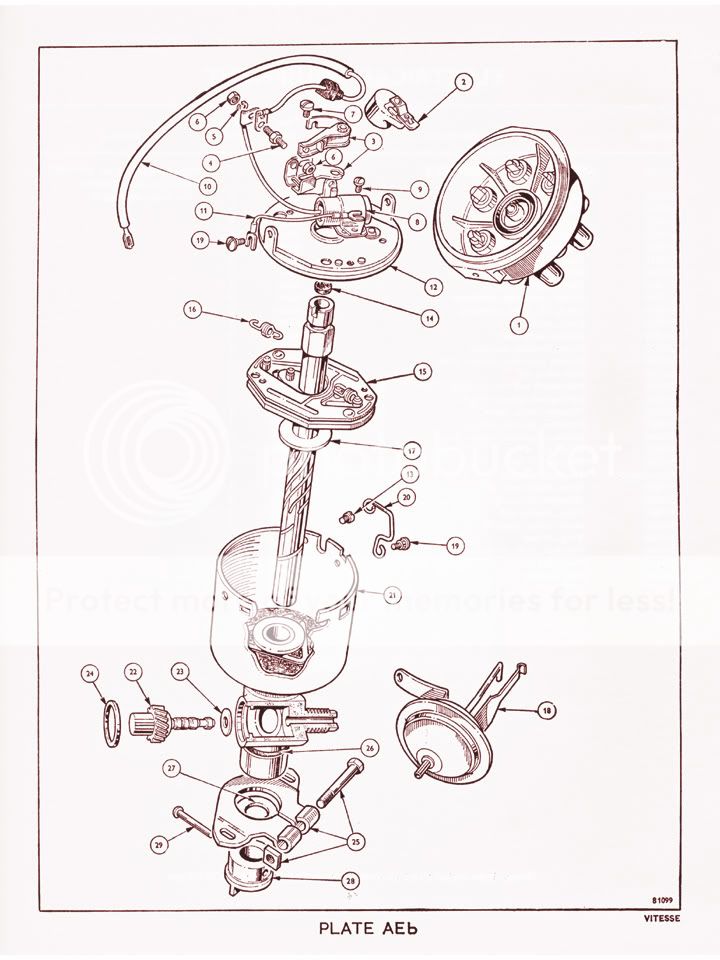

1. what is the size of the "washer"? Part #17 in the diagram. as you can see in the last pic...mine is shot.

2. can it be made of something besides metal? i have a block of teflon here at work that i may be able to fabricate a washer from.

3. how much oil do you put down the hole in the top plate? and will putting oil there help this problem from happening again? seems like a poor design if this washer is the only thing holding up the shaft.

4. what kind of greese do i pack in the tach drive gear?

5. anyone have a gently used vac advance can and top plate for sale (parts 12 and 18) that would fit this distributor?

thanks,

Bill

my questions are:

1. what is the size of the "washer"? Part #17 in the diagram. as you can see in the last pic...mine is shot.

2. can it be made of something besides metal? i have a block of teflon here at work that i may be able to fabricate a washer from.

3. how much oil do you put down the hole in the top plate? and will putting oil there help this problem from happening again? seems like a poor design if this washer is the only thing holding up the shaft.

4. what kind of greese do i pack in the tach drive gear?

5. anyone have a gently used vac advance can and top plate for sale (parts 12 and 18) that would fit this distributor?

thanks,

Bill

Hi Guest!

Hi Guest!

smilie in place of the real @

smilie in place of the real @

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

Pretty Please - add it to our Events forum(s) and add to the calendar! >>