crj7driver

Jedi Trainee

Offline

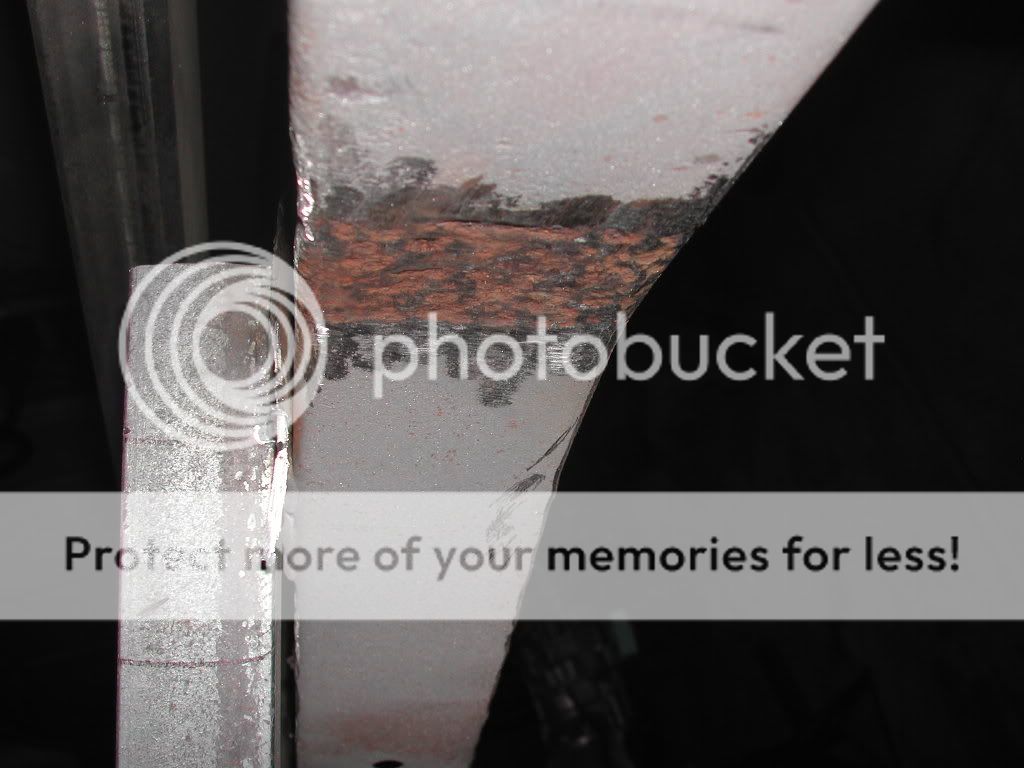

I am in the process of resurrecting my frame to some level of safety and rigidity. The frame is solid except for the trailing arm attachment points and one area in the waist. When I cut one of the trailing arms out, the area where the trailing arm meets the center of the frame is heavily pitted. It appears structurally sound (i.e. if I take a screwdriver and try and hammer it through the frame it does not give or dent).

So the question is, do I

A. Leave it alone and just clean the rust up

B. Cut the section out and weld in a patch piece

C. Weld a doubling plate over the area after I clean

it up

D. Do B & C

E. Something else?

Thanks for any and all help. I just want to do it the best way possible as long as I have the frame torn apart.

So the question is, do I

A. Leave it alone and just clean the rust up

B. Cut the section out and weld in a patch piece

C. Weld a doubling plate over the area after I clean

it up

D. Do B & C

E. Something else?

Thanks for any and all help. I just want to do it the best way possible as long as I have the frame torn apart.

Hi Guest!

Hi Guest!

smilie in place of the real @

smilie in place of the real @

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

Pretty Please - add it to our Events forum(s) and add to the calendar! >>