bigjones

Jedi Warrior

Offline

No, I'm not getting any ideas!

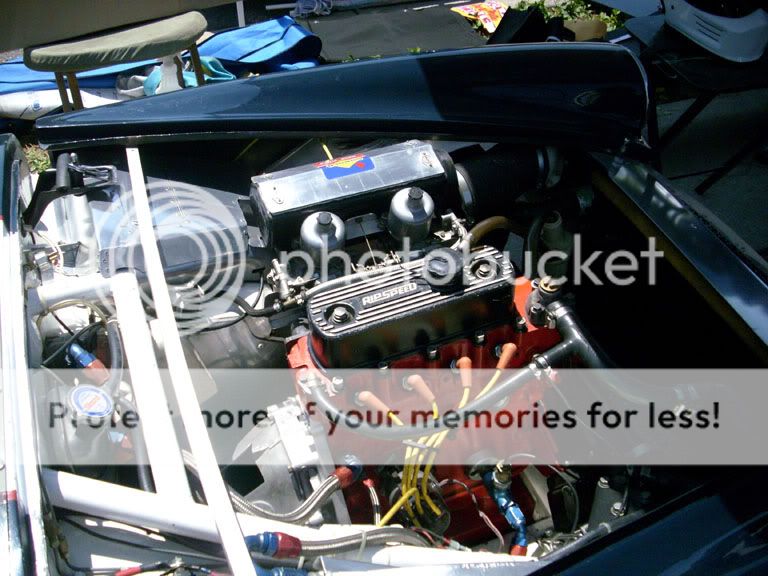

At the last car show, I was looking under the hood of our local resident MG Midget racer and was very impressed with how things were made from sheets of aluminum (I think). For example, the air filter housing, or more correctly called, I suppose, the "air box", as it extended to the front of the car for a ram effect. This was obviously home made but very neatly done - sort of like an aircraft wing but with Allen bolts, I think, instead of rivets.

Where do you get this aluminum from and what thickness? How do they cut this aluminum - surely not with a hack saw. Band saw wouldn't give a straight line, if I was using it, ha! Prolly a table saw with special blade, right? What is the recommended hardware used that bolts it all together?

Cheers!

(still waiting on head gasket)

Hi Guest!

Hi Guest!

smilie in place of the real @

smilie in place of the real @

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

Pretty Please - add it to our Events forum(s) and add to the calendar! >>