SNClocks

Member

Offline

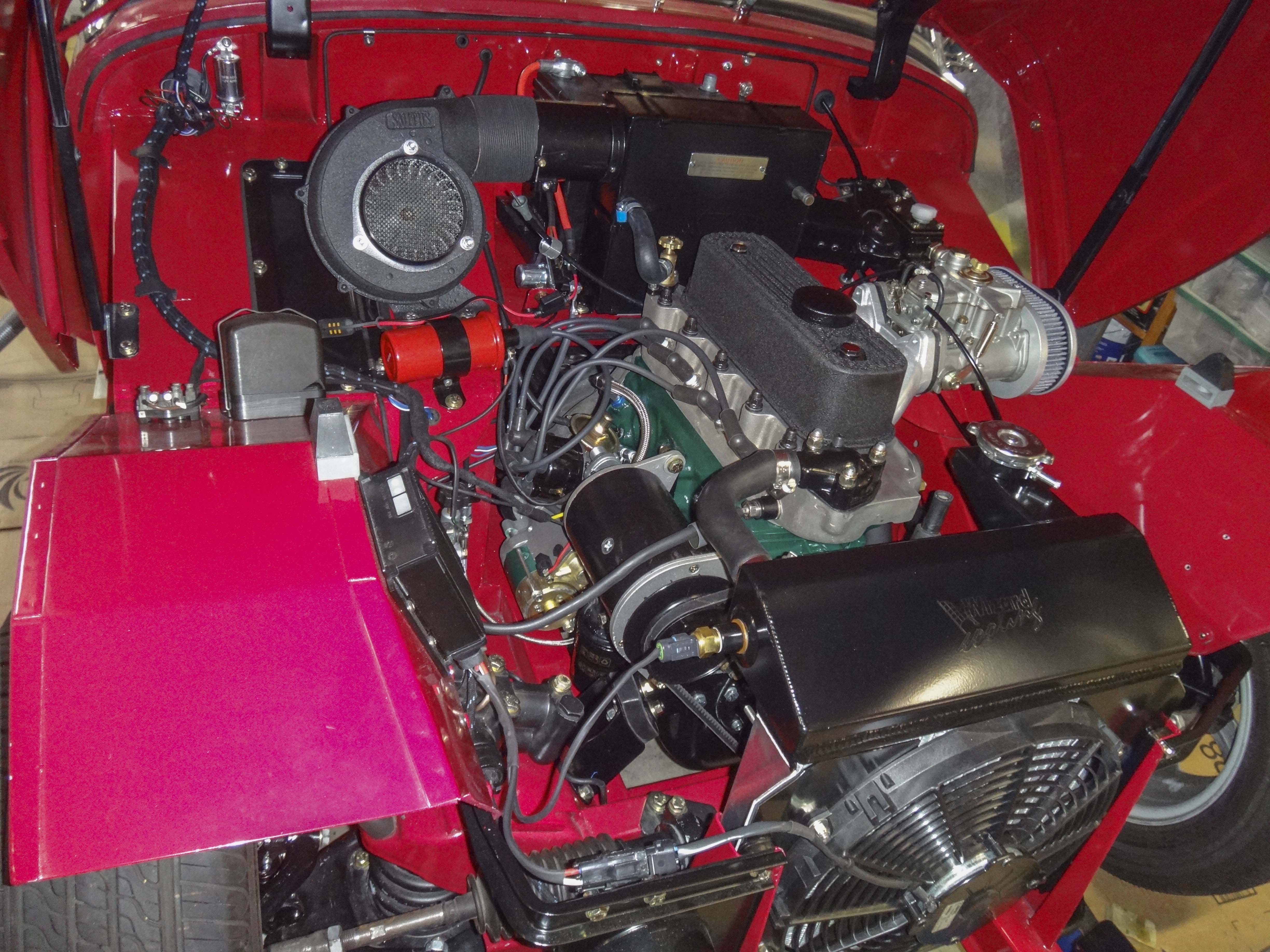

Getting one's shoulder replaced is not for the faint of heart. Nonetheless I have been able to make some progress, even though one arm is next to useless. I finished up work on the Weber DCOE 40, rejetted to my best guess of what it should be, set up the choke cable (which meant replacing the original steel wire/housing with braided bicycle cable and lined bicycle cable housing), and upgraded/powdercoated the air cleaner housing.

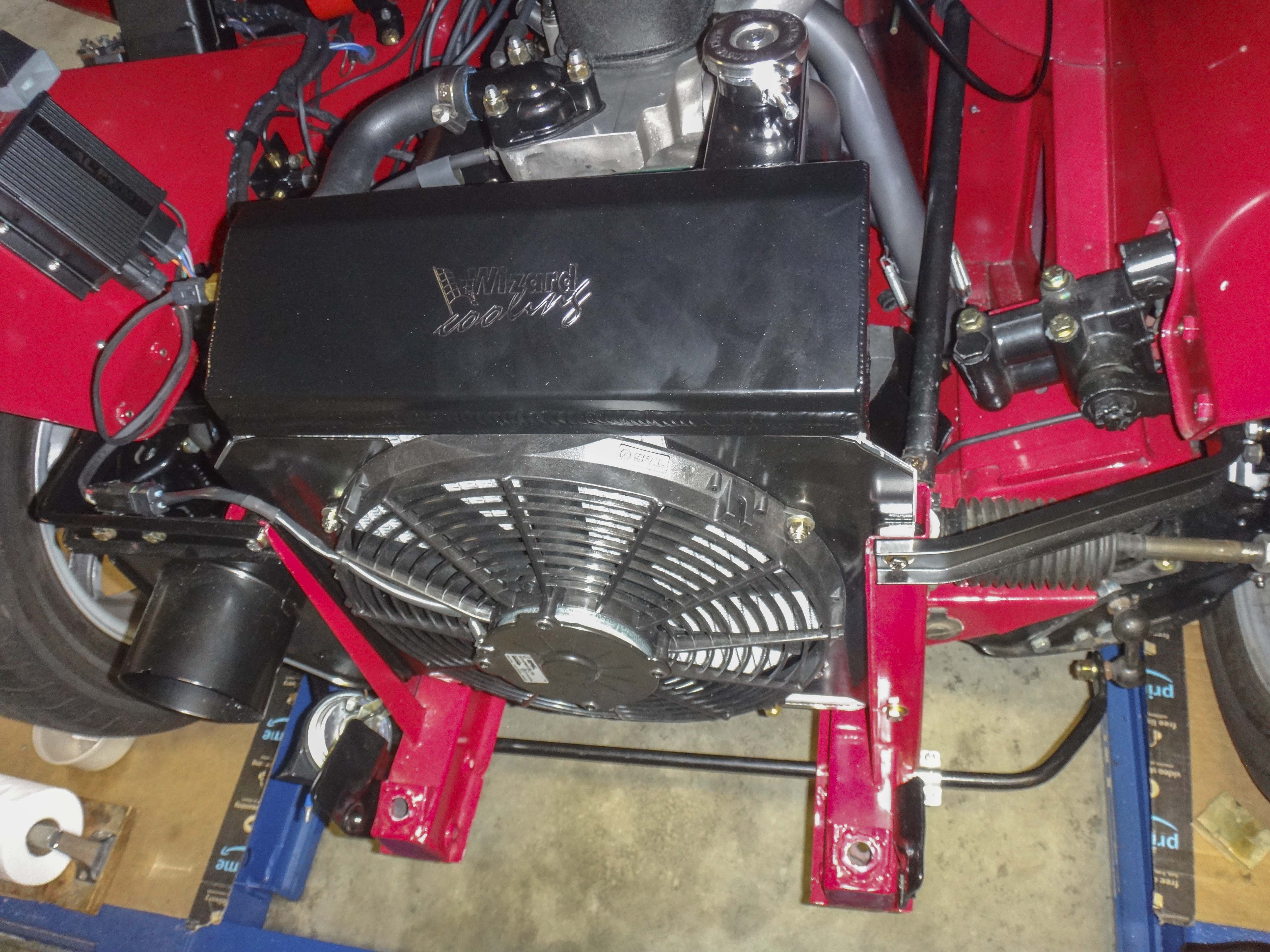

Next I powdercoated the top tank on the new aluminum radiator and got it installed. I shot some pictures of the custom shroud I made-up for the new SPAL fan. Overall it took some cutting and modifying of the radiator to get it to fit such that the fan motor does not foul the back lip of the bonnet air inlet opening. I think it came out slick.

I got set up sometime ago to powdercoat my wood shop. It already had a dust collection system so that part of powder coating was easy. I also had an old home oven over in the corner to heat treat metal, which also allows me to bake power coat. Only thing left was a powder coat system. Initially I used Eastwood's inexpensive system which works well enough, once you figure you have to use electrical tape to seal the powder jar to the gun. I have to admit upgrading to their nicer system makes powder coating a lot of fun.

I've included a shot of the radiator in my oven. The shot shows the radiator after I've removed the masking tape and ready for its final cure - I've learned that leaving the masking tape on for the cure results in silicone masking tape that's very tough to get off of the work piece.

If y'all are interested I could put together a short tech article on powder coating.

I'm off to go stretch my shoulder and put in a bit more work on the bug eye.

Next I powdercoated the top tank on the new aluminum radiator and got it installed. I shot some pictures of the custom shroud I made-up for the new SPAL fan. Overall it took some cutting and modifying of the radiator to get it to fit such that the fan motor does not foul the back lip of the bonnet air inlet opening. I think it came out slick.

I got set up sometime ago to powdercoat my wood shop. It already had a dust collection system so that part of powder coating was easy. I also had an old home oven over in the corner to heat treat metal, which also allows me to bake power coat. Only thing left was a powder coat system. Initially I used Eastwood's inexpensive system which works well enough, once you figure you have to use electrical tape to seal the powder jar to the gun. I have to admit upgrading to their nicer system makes powder coating a lot of fun.

I've included a shot of the radiator in my oven. The shot shows the radiator after I've removed the masking tape and ready for its final cure - I've learned that leaving the masking tape on for the cure results in silicone masking tape that's very tough to get off of the work piece.

If y'all are interested I could put together a short tech article on powder coating.

I'm off to go stretch my shoulder and put in a bit more work on the bug eye.

Hi Guest!

Hi Guest!

smilie in place of the real @

smilie in place of the real @

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

Pretty Please - add it to our Events forum(s) and add to the calendar! >>