I am currently restoring a BJ7 Heaely which unfortunately I did not dis-assemble. Is there a specific position for the 2 dowell bolts ( aec3487) on the bell housing ? There is a total of 7 bolts on the housing. I have restored E types and Mark2 Jags. before but a Healey is new to me

-

Hi Guest!

Hi Guest!

You can help ensure that British Car Forum (BCF) continues to provide a great place to engage in the British car hobby! If you find BCF a beneficial community, please consider supporting our efforts with a subscription.

There are some perks with a member upgrade!**Upgrade Now**

(PS: Subscribers don't see this gawd-aweful banner

Tips

- We have a special forum called "Member Articles" where you can submit actual articles for consideration for publication. Learn More

- Don't have an Avatar? If not, your avatar will default to the 1st character in your username. Go into "Account Details" to change your Avatar.

- Some basic forum navigation info: click

Hey - did you know if you click on the title of a thread it will take you to the first unread post since you last visited that thread?

- Hey Guest - Is your British Car Club in our Clubs database? If not, send me a PM - Basil

- Looking for a local club? Click the "Clubs" tab above and browse hundreds of clubs world-wide.

- Add Android or iPhone APP: click

- Did you know - any picture or video you add in your posts in any marque-specific forum will also get added to the Media Gallery automatically.

- A few more tips about posting and replying: click

- Hey there Guest - be sure to keep your profile page up to date with interesting info about yourself: learn more

- More tips and tricks on Posting and Replying: click

STOP!! Never post your email address in open forums. Bots can "harvest" your email! If you must share your email use a Private Message or use the

STOP!! Never post your email address in open forums. Bots can "harvest" your email! If you must share your email use a Private Message or use the  smilie in place of the real @

smilie in place of the real @

- Want to mention another member in a post & get their attention? WATCH THIS

- So, you created a "Group" here at BCF and would like to invite other members to join? Watch this!

- Hey Guest - A post a day keeps Basil from visiting you in the small hours and putting a bat up your nightdress!

- Hey Guest - do you know of an upcoming British car event?

Pretty Please - add it to our Events forum(s) and add to the calendar! >> Here's How <<

Pretty Please - add it to our Events forum(s) and add to the calendar! >> Here's How <<

- Hey Guest - you be stylin'

Change the look and feel of the forum to fit your taste. Check it out

- If you run across an inappropriate post, for example a post that breaks our rules or looks like it might be spam, you can report the post to the moderators: Learn More

- If you would like to try some different "looks" or styles for the site, scroll to the very bottom, on the left and click the Style Selector.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Position of dowell bolts on Healey bell housing

- Thread starter bj7

- Start date

Robert560

Senior Member

Offline

If you have the ability to measure the holes in the bellhousing and back plate through which the bolts pass, you'll notice that two measure a bit smaller than the others... they measure right around 0.375", if memory serves, while the others are like the next drill size up... like 13/32" or something.

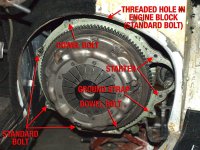

Looking at the transmission from the REAR of the car, the two smaller holes for dowel bolts should be at the 11 o'clock position and then about 180 degrees from that at the 5 o'clock position. So on top, it's the hole opposite the one that threads into the engine block, and then 180 degrees from that one, under where the starter mounts.

FYI, for you or others, I ended up just using AN176 aircraft bolts in these holes, which are basically exactly what the original "dowel bolts" were (was missing one of my original dowel bolts). They cost me like $0.50 each.

Regards,

Robert

Looking at the transmission from the REAR of the car, the two smaller holes for dowel bolts should be at the 11 o'clock position and then about 180 degrees from that at the 5 o'clock position. So on top, it's the hole opposite the one that threads into the engine block, and then 180 degrees from that one, under where the starter mounts.

FYI, for you or others, I ended up just using AN176 aircraft bolts in these holes, which are basically exactly what the original "dowel bolts" were (was missing one of my original dowel bolts). They cost me like $0.50 each.

Regards,

Robert

Johnny

Darth Vader

Offline

Can't add much to what already was said, other than if you have the original bolts you'll notice they are a tighter fit in the dowel bolt positions than the other bolts.

Can't add much to what already was said, other than if you have the original bolts you'll notice they are a tighter fit in the dowel bolt positions than the other bolts.good luck fitting the transmission back, read my post on installing the transmission back in the car. Definetly a two man job.

GregW

Yoda

Offline

I believe the ground strap goes in the next hole up from the dowel pin. It was inline with the clutch slave on my BJ8, though it could have been put back wrong in the past (a new clutch had been installed). Putting it there makes more sense to me. 1) It reaches the frame mounting point, 2) It is less likely to get hit by things in/on the road.bj7 said:I think one of the dowelled bolts actually holds the earth strap ?

Attachments

Keoke

Great Pumpkin

Offline

Well lets look at the Ground stap'e location from an electrical standpoint, Here it is desirable to have the lowest resistance at the engine interface,Consequently. the strap would then connect to the lower starter attaching bolt.

This is in line with the preferred method defined in this thread.--Fwiw--Keoke

This is in line with the preferred method defined in this thread.--Fwiw--Keoke

Guy Marshall

Member

Offline

Hi guys - an old thread but a goodie.

One more question - which way should the bellhousing bolts point? The bottom couple have to be "nuts forward" but is that true of the others? Normally I'd like to see the nuts at the back.

I realise this is maybe unimportant, except for the dowel bolts which are proving very tight on my BN6... Any thoughts?

One more question - which way should the bellhousing bolts point? The bottom couple have to be "nuts forward" but is that true of the others? Normally I'd like to see the nuts at the back.

I realise this is maybe unimportant, except for the dowel bolts which are proving very tight on my BN6... Any thoughts?

Keoke

Great Pumpkin

Offline

Don't know if it's correct or not, but my ground strap was indeed attached to the dowel bolt. I put it back the same way.

Regards,

Robert

That is ok as electrically speaking either location is the same.

Offline

Hi guys - an old thread but a goodie.

One more question - which way should the bellhousing bolts point? The bottom couple have to be "nuts forward" but is that true of the others? Normally I'd like to see the nuts at the back.

I realise this is maybe unimportant, except for the dowel bolts which are proving very tight on my BN6... Any thoughts?

I found it easier with the nuts at the front because I could hang a combination wrench off them when I tightened the bolts from the rear. The Moss catalog factory drawings show all the bell-housing-to-rear-plate bolts pointing forward.

Last edited:

Randy Forbes

Yoda

Offline

From a practical standpoint__which possibly flies in the face of a concours aplication__I try to have the nuts/exposed facing to the rear.Hi guys - an old thread but a goodie.

One more question - which way should the bellhousing bolts point? The bottom couple have to be "nuts forward" but is that true of the others? Normally I'd like to see the nuts at the back.

I realise this is maybe unimportant, except for the dowel bolts which are proving very tight on my BN6... Any thoughts?

My line of thinking is that the exposed threads are less susceptible to being damaged by thrown up rocks and road debris, and may collect less grime and grit in them, making for an easier removal. Your experiences may differ.

I find that even my modern (well, significantly more modern than a Healey) sportscars have factory bolts with the threads-forward, even when they are easily reversed__which I do when serviced__so does anyone have empirical data, from an engineering standpoint, why they should face either direction?

Offline

....so does anyone have empirical data, from an engineering standpoint, why they should face either direction?

No data, but guessing on the factory assembly line, it must be slightly easier/quicker with bolts forward.

Offline

I think that perhaps it stems from early aviation when folks were taught that when possible bolts should be installed with heads facing forward or heads facing inboard if rotating as in a helicopter rotor; the belief was/is that if a nut were to be left off or vibrated off ( not properly safetied etc.) the slipstream might keep the bolt in place or in the case of the rotating assembly, centrifugal force would do the same. While there may be a bit of truth to this it bears little on the bolts in question in this thread. Being a retired A& P mechanic I tend to follow the tradition unless there is a common sense reason not to, such as bleing able to remove the hardware more easily one way. Make sure things are properly torqued and use a thread locker on stuff you are not likley to want coming loose. And for all you concourse slaves (not being snarky here, just that that that aspect of Healey ownership has some clear limits for me) do what the judges expect to see.

Online

"Concours," perhaps the most misunderstood and inappropriately maligned aspect of the car hobby. It's most typically denigrated by those who've never come close to one.

I don't know how anyone expects concours judges to see these bolts. We don't dismantle the cars, we don't slide mirrors under the car in search of dust particles on top of the exhaust pipes, and we don't have x-ray vision. Although it is kind of cool to be believed to possess superpowers - "Concours Man" sees ALL, deducts for EVERYTHING!

I don't know how anyone expects concours judges to see these bolts. We don't dismantle the cars, we don't slide mirrors under the car in search of dust particles on top of the exhaust pipes, and we don't have x-ray vision. Although it is kind of cool to be believed to possess superpowers - "Concours Man" sees ALL, deducts for EVERYTHING!

Offline

I think that perhaps it stems from early aviation when folks were taught that when possible bolts should be installed with heads facing forward or heads facing inboard if rotating as in a helicopter rotor; the belief was/is that if a nut were to be left off or vibrated off ( not properly safetied etc.) the slipstream might keep the bolt in place or in the case of the rotating assembly, centrifugal force would do the same. While there may be a bit of truth to this it bears little on the bolts in question in this thread. Being a retired A& P mechanic I tend to follow the tradition unless there is a common sense reason not to, such as bleing able to remove the hardware more easily one way. Make sure things are properly torqued and use a thread locker on stuff you are not likley to want coming loose. And for all you concourse slaves (not being snarky here, just that that that aspect of Healey ownership has some clear limits for me) do what the judges expect to see.

Quibble: aviation more likely to follow automotive practice than the other way around.

By this logic, the factory made a good choice by having the bell housing bolts point forward: since braking force is greater than acceleration, the bolt is more likely to stay in place if the nut falls off.