Hi All,

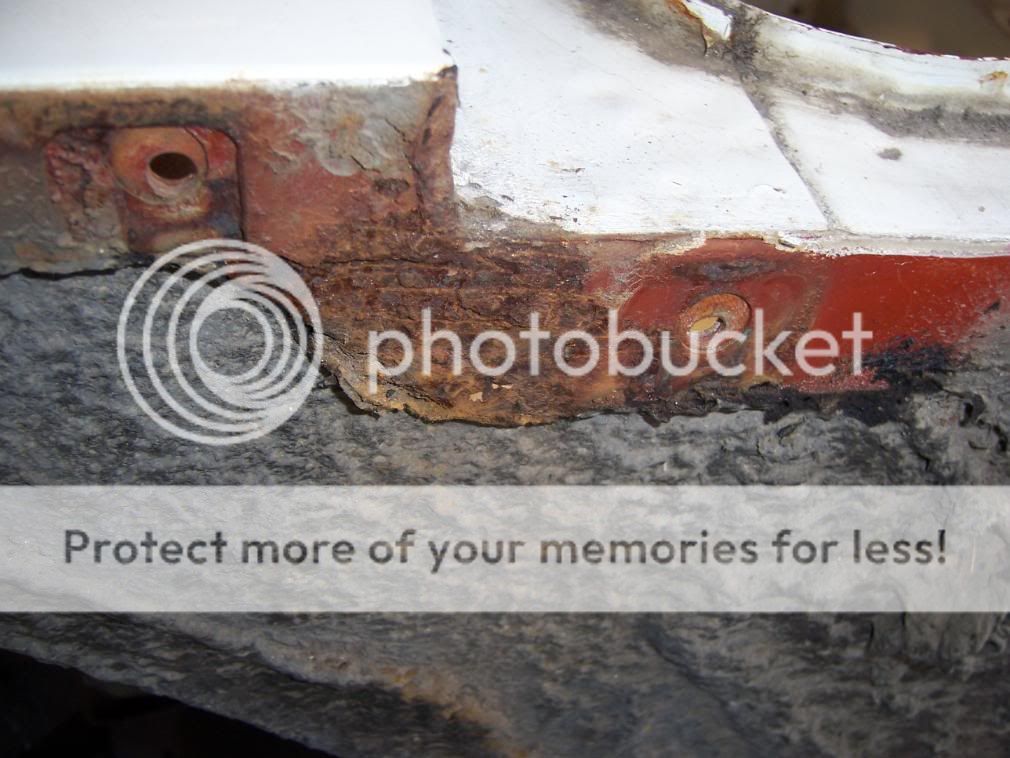

I have some rot at the place where the rear fenders attach to the deck on both sides of my 6. They had been brazed on, not during my ownership.

This is about the same on the other side of the car as well.

In the picture you can see where the fender had been brazed to the rear deck. I expect that the cause of the rusting is the flux from the brazing process. Fortunately both the fenders are in pretty good shape, only one has a rust hole that I can patch up by welding in some sheet metal. Other than the holes shown above the rear deck is in good shape. I do have a used deck panel and extensions to replace the ones that are on the car.

What I need the opinions which way to proceed.

Option 1, I can remove the existing deck and weld the replacement one on. This would be quite labour intensive (have to clean up the replacement panel drill out spot welds etc. etc. ) Fix up fenders and bolt them back on.

Option 2, patch up the holes by welding some new sheet metal in, then weld the fenders back on (same as would be done in a modern car with quarter panels) cover welds with fiberglass filler etc. to get the smooth look.

I should add that I am in the beginning stages of a frame off restoration but I do have limited time, only a few hours a week to work on it. I am leaning towards option 2 as its a lot less work and I wont have to go to the effort of having a nice "gap" between the fender and the deck. My concern with option 2 is that the weld may crack some time in the future or cause structural problems.

Thanks in advance.

Todd

I have some rot at the place where the rear fenders attach to the deck on both sides of my 6. They had been brazed on, not during my ownership.

This is about the same on the other side of the car as well.

In the picture you can see where the fender had been brazed to the rear deck. I expect that the cause of the rusting is the flux from the brazing process. Fortunately both the fenders are in pretty good shape, only one has a rust hole that I can patch up by welding in some sheet metal. Other than the holes shown above the rear deck is in good shape. I do have a used deck panel and extensions to replace the ones that are on the car.

What I need the opinions which way to proceed.

Option 1, I can remove the existing deck and weld the replacement one on. This would be quite labour intensive (have to clean up the replacement panel drill out spot welds etc. etc. ) Fix up fenders and bolt them back on.

Option 2, patch up the holes by welding some new sheet metal in, then weld the fenders back on (same as would be done in a modern car with quarter panels) cover welds with fiberglass filler etc. to get the smooth look.

I should add that I am in the beginning stages of a frame off restoration but I do have limited time, only a few hours a week to work on it. I am leaning towards option 2 as its a lot less work and I wont have to go to the effort of having a nice "gap" between the fender and the deck. My concern with option 2 is that the weld may crack some time in the future or cause structural problems.

Thanks in advance.

Todd

Hi Guest!

Hi Guest!

smilie in place of the real @

smilie in place of the real @

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

Pretty Please - add it to our Events forum(s) and add to the calendar! >>