Morris

Yoda

Offline

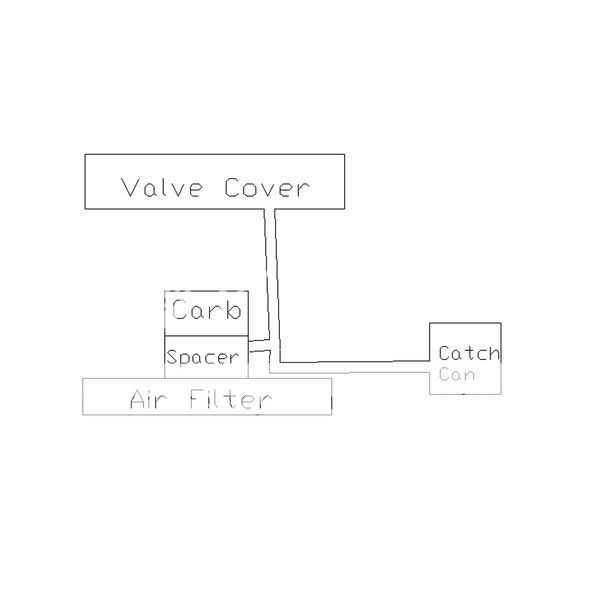

I have hooked up a Wideband 02 sensor to my '79 Midget, and I believe the blow by in my engine is corrupting my signal. With the crankcase vent tube plugged into the carb, the car reads a little richer than without. This seems to be regardless of whether or not the tube to the charcoal canister is plugged in.

Is there a way to vent the crank case without plugging into the carb? If I just pull the tube and allow it to vent to air, oil blows out the dip stick when the engine is under load.

morris

Is there a way to vent the crank case without plugging into the carb? If I just pull the tube and allow it to vent to air, oil blows out the dip stick when the engine is under load.

morris

Hi Guest!

Hi Guest!

smilie in place of the real @

smilie in place of the real @

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

Pretty Please - add it to our Events forum(s) and add to the calendar! >>