Offline

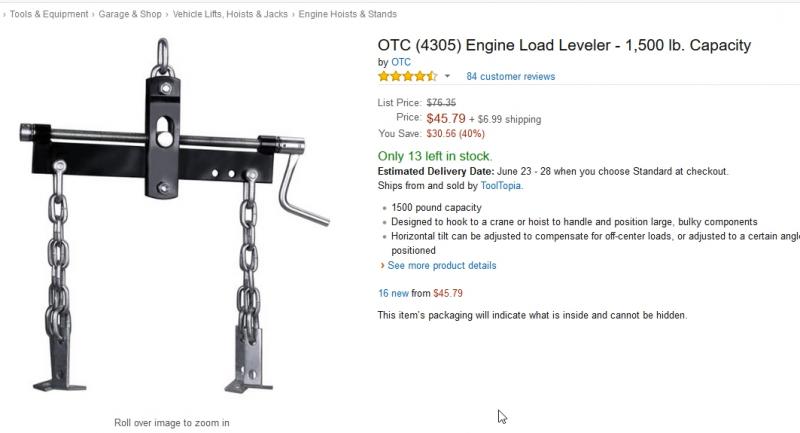

I'm looking at these two items for pulling my engine:

I have a Toyota trans - Is it best to pull engine & trans together?

Or can I first remove the trans, then pull the engine?

Will the HF crane with this load leveller be able to lift the engine enough to clear the shroud?

Does one pull the engine then push the car out from under it?

Should I pull the head separately, then the engine?

Thanks for any pointers.

I have a Toyota trans - Is it best to pull engine & trans together?

Or can I first remove the trans, then pull the engine?

Will the HF crane with this load leveller be able to lift the engine enough to clear the shroud?

Does one pull the engine then push the car out from under it?

Should I pull the head separately, then the engine?

Thanks for any pointers.

Hi Guest!

Hi Guest!

smilie in place of the real @

smilie in place of the real @

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

Pretty Please - add it to our Events forum(s) and add to the calendar! >>