Offline

After showing suspiciously high oil temperatures during normal driving on cool days, I decided to test my new temp gauge.

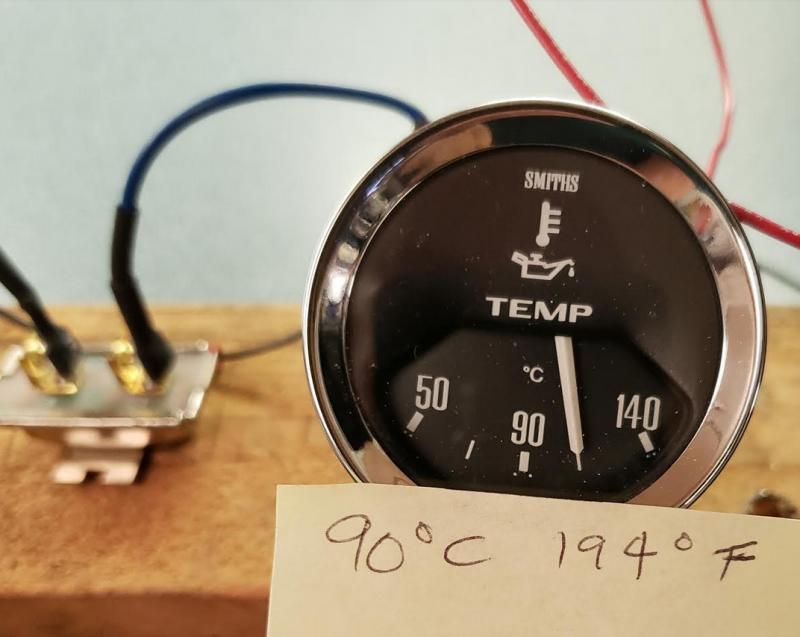

With the sender immersed in 90 C / 194 F water, here's the result. 40 ohms in series with the sender brings the needle back to 90:

Lots of folks online are saying their Smith's electronic gauges run 15% high and that the problem is in the senders.

According to one, Nisonger claims to sell accurate senders.

With the sender immersed in 90 C / 194 F water, here's the result. 40 ohms in series with the sender brings the needle back to 90:

Lots of folks online are saying their Smith's electronic gauges run 15% high and that the problem is in the senders.

According to one, Nisonger claims to sell accurate senders.

Hi Guest!

Hi Guest!

smilie in place of the real @

smilie in place of the real @

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

Pretty Please - add it to our Events forum(s) and add to the calendar! >>