5

57_BN4

Guest

Guest

Offline

I bought a reproduction AZX 1331 SU pump a couple of years ago and it looks well built and fairly authentic. After less than ten hours use it started making odd noises so I removed the top cap and was greeted by a strong smell of petrol and a set of dirty looking points.

I contacted Burlen Fuel Systems about these two issues and after several emails went unanswered I rang them and they sent another set of points (my cost).

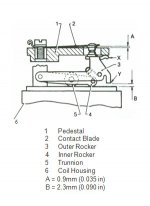

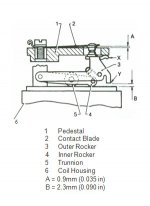

The original points were perfectly serviceable but I replaced them anyway and subsequently discovered the cause of the noise was that the factory-set points gap was far too small so as the diaphragm descended, instead of snapping sharply closed, the points just wandered closed and bounced around during the contact phase. This was the source of the odd scrunching noise I was hearing. There is a little tag on the end of the points plate which sets the gap (B in the diagram below) and after bending this up I got a decent snap shut of the points. The Burlen factory had left the gap at around 0.040. The pump operation is now much slower because the stroke is over twice as long which should equal longer life.

The second issue was the fuel smell which I discussed with Burlen and they offered a replacement diaphragm at my cost since it was conveniently out of warranty. There is nothing wrong with the original diaphragm that I can see apart from appearing to be badly engineered. The original SU diaphragm is a multi-layered affair with plastic and rubber layers to prevent fuel getting to the other side. The reproduction diaphragm is a single piece cut from a sheet of fabric-reinforced rubber and IMO is allowing fuel to pass through it via osmosis. This seems to be a fairly good fire hazard- fuel vapor in an enclosed space with sparking points.

Questions:

1) Is anyone else using a modern SU pump and hearing a "scrunch-scrunch-scrunch" noise which reverts to normal operation, only to do it again half a minute later?

2) Has anyone replaced a diaphragm with the modern single-layer one and then checked for fuel smell inside the pump?

Andy.

I contacted Burlen Fuel Systems about these two issues and after several emails went unanswered I rang them and they sent another set of points (my cost).

The original points were perfectly serviceable but I replaced them anyway and subsequently discovered the cause of the noise was that the factory-set points gap was far too small so as the diaphragm descended, instead of snapping sharply closed, the points just wandered closed and bounced around during the contact phase. This was the source of the odd scrunching noise I was hearing. There is a little tag on the end of the points plate which sets the gap (B in the diagram below) and after bending this up I got a decent snap shut of the points. The Burlen factory had left the gap at around 0.040. The pump operation is now much slower because the stroke is over twice as long which should equal longer life.

The second issue was the fuel smell which I discussed with Burlen and they offered a replacement diaphragm at my cost since it was conveniently out of warranty. There is nothing wrong with the original diaphragm that I can see apart from appearing to be badly engineered. The original SU diaphragm is a multi-layered affair with plastic and rubber layers to prevent fuel getting to the other side. The reproduction diaphragm is a single piece cut from a sheet of fabric-reinforced rubber and IMO is allowing fuel to pass through it via osmosis. This seems to be a fairly good fire hazard- fuel vapor in an enclosed space with sparking points.

Questions:

1) Is anyone else using a modern SU pump and hearing a "scrunch-scrunch-scrunch" noise which reverts to normal operation, only to do it again half a minute later?

2) Has anyone replaced a diaphragm with the modern single-layer one and then checked for fuel smell inside the pump?

Andy.

Hi Guest!

Hi Guest!

smilie in place of the real @

smilie in place of the real @

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

Pretty Please - add it to our Events forum(s) and add to the calendar! >>