BMCMidgetLover

Freshman Member

Offline

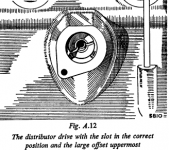

A 1275 has been rebuilt, and now when the timing mark is at its spot on the timing marks, the number 4 cylinder is closed and #1 valves are rocking. When you put the distributor in it wants to fire #4. Referring to Robert Bently's fig A12 on page 62 the left is up and the right is down. Could the number #4 be used to time the motor or does the motor have to come a part?

Hi Guest!

Hi Guest!

smilie in place of the real @

smilie in place of the real @

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

Pretty Please - add it to our Events forum(s) and add to the calendar! >>