T

Tinster

Guest

Guest

Offline

My new rocker arm shaft arrived today . HooRah!!!

(double mailed to save the $60. seller shipping charge)

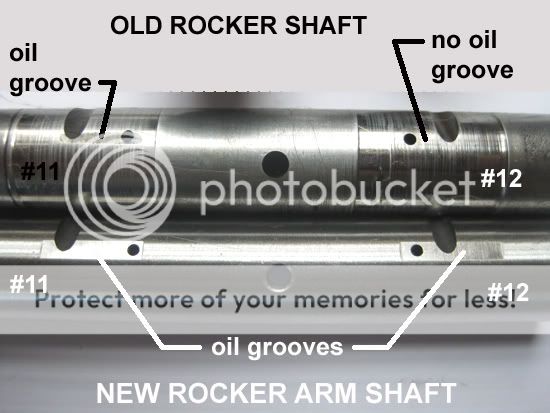

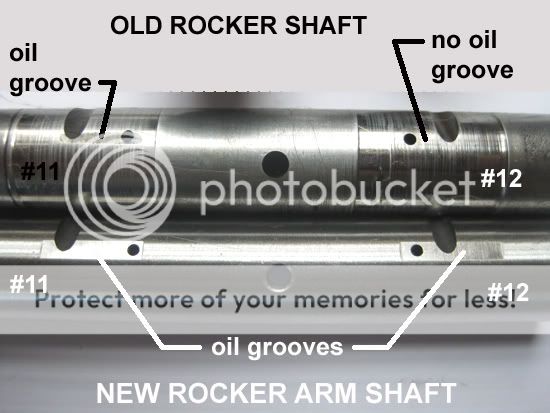

Here's a photo side by side of old and new shafts at

rockers No. 11 and No. 12. Clearly the rocker shaft that

I removed was defective when it left the point of manufacture.

The missing oil groove explains dry rocker No. 12 and low oil

pressure that resulted in dry Rocker No. 1.

I can't wait to put everything back together and see how things

are supposed to operate. PS: Paul- both shaft ends

are threaded to accept hex socket, tapered end bolts.

regards,

dale(Tinster)

(double mailed to save the $60. seller shipping charge)

Here's a photo side by side of old and new shafts at

rockers No. 11 and No. 12. Clearly the rocker shaft that

I removed was defective when it left the point of manufacture.

The missing oil groove explains dry rocker No. 12 and low oil

pressure that resulted in dry Rocker No. 1.

I can't wait to put everything back together and see how things

are supposed to operate. PS: Paul- both shaft ends

are threaded to accept hex socket, tapered end bolts.

regards,

dale(Tinster)

Hi Guest!

Hi Guest!

smilie in place of the real @

smilie in place of the real @

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

Pretty Please - add it to our Events forum(s) and add to the calendar! >>