britndablood

Member

Offline

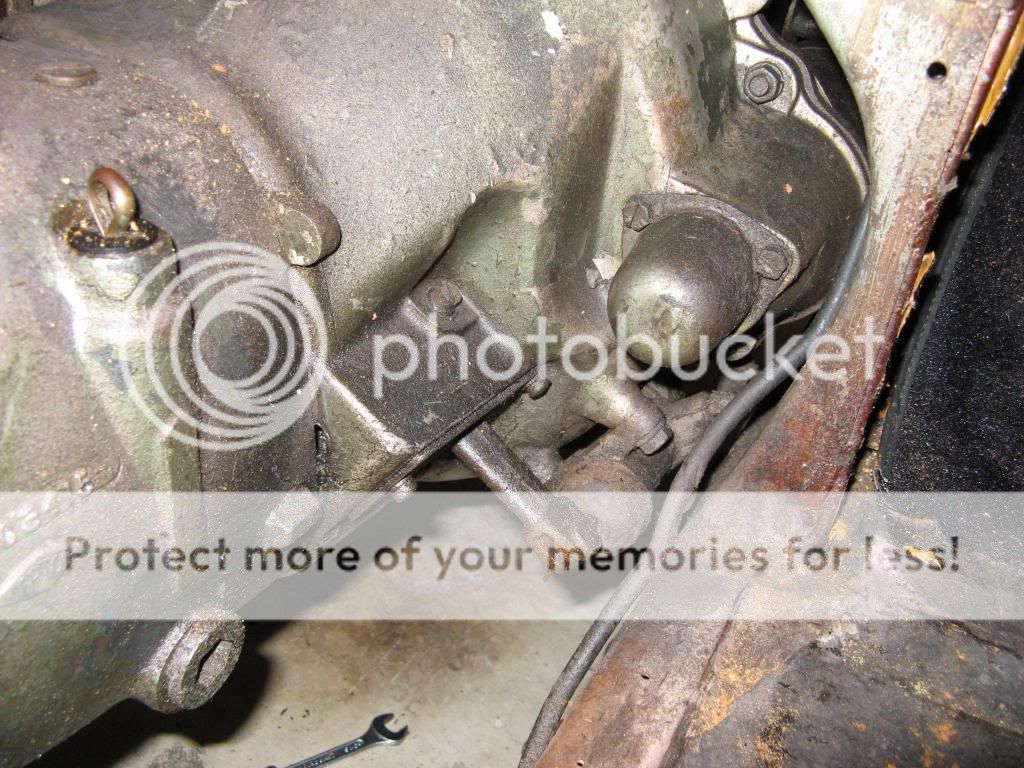

The clutch lasted for one drive around the block. It will not disengage. I took the slave off this morning and found the PO installed a 1/4" drive 3/8" socket on the end of the push rod connecting the slave to the release bearing fork. Making it longer. I rebuilt the slave and put in a new push rod. I noticed on the install that there was 1" of play in the release bearing fork before it touches the pressure plate. Also pushing in the clutch now will kill the engine and not disengage the clutch. I am looking for suggestion and maybe reassurance on what I suspect. Which is the release bearing is worn into the steel and now needs to travel further to hence the socket by the PO and the lack of bearing draging on the pressure plate causing the engine to die.

Hi Guest!

Hi Guest!

smilie in place of the real @

smilie in place of the real @

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

Pretty Please - add it to our Events forum(s) and add to the calendar! >>