Steve G.

I have not fabricated the bracket or bracket adapter as yet and I keep the car at my summer place in Southampton, NY about 70 miles from where I live here in Oceanside, NY.

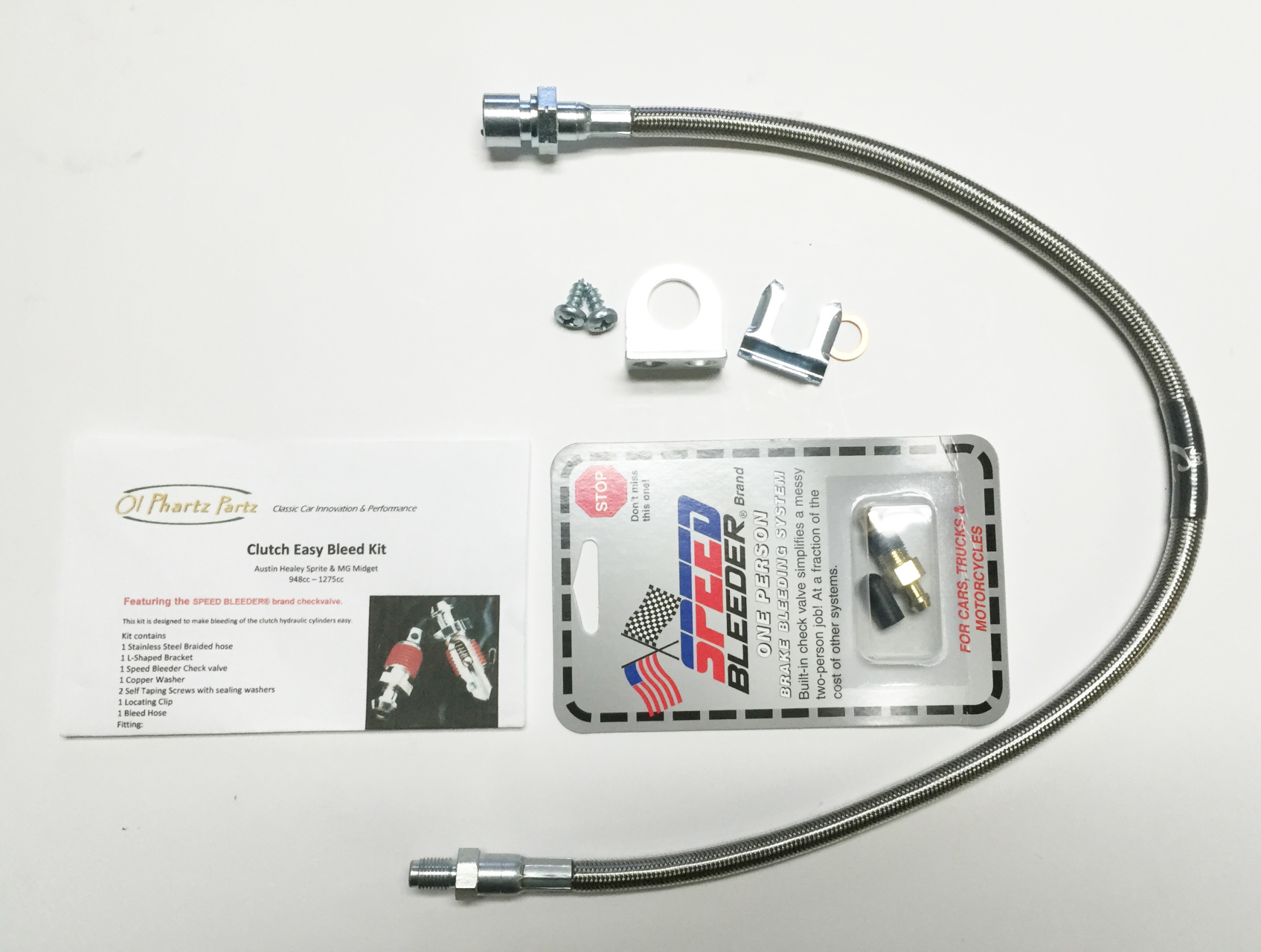

The bracket that comes with the kit can be used "as is" if attached to the inside frame opposite and slightly to the rear of the distributor, forward of the starting solenoid. The bracket is clearly seen in the photo above just above the SpeedBleeder fitting package.

I was thinking of making a simple bracket similar to what Drone Dog did as shown in his photograph - attached to the upper bolt for the starter.

Alternatively, I may drill two small holes to the protruding lip on the fender side of the starter solenoid and attach a fabricated adapter bracket that would accommodate the one supplied by Steve Christiansen.

As a temporary measure I just have the extension brake (clutch) line tie-wrapped in place pending a more elegant mounting solution as described above.

The main reason for the original post was to make folks aware that a reasonably priced kit exists made up of quality parts that can be easily installed, minus the rather small challenge of adapting the mounting plate.

I'll come back to this thread when I have mounted the bleeder and and I have taken photos.

~ Joe

Hi Guest!

Hi Guest!

smilie in place of the real @

smilie in place of the real @

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

Pretty Please - add it to our Events forum(s) and add to the calendar! >>