Online

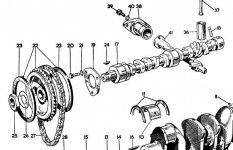

Back to working on my 1275 rebuild. Put in the camshaft (stock), but it seems to slide about 50 mils too far toward the rear of the engine, giving me ~50 mils of end float instead of the requisite 3-7 mils. Problem is, I can't see what locates the camshaft at the rear of the engine. It just seems to slide into the oil pump a bit too far.

I suspect I'm missing a washer or something similar, which I could have lost in cleaning or perhaps it just wasn't there in the first place--I wouldn't have noticed on tear down.

Attached is a picture of the oil pump--anyone see anything missing? Or, is there something else that locates the camshaft?

I suspect I'm missing a washer or something similar, which I could have lost in cleaning or perhaps it just wasn't there in the first place--I wouldn't have noticed on tear down.

Attached is a picture of the oil pump--anyone see anything missing? Or, is there something else that locates the camshaft?

Hi Guest!

Hi Guest!

smilie in place of the real @

smilie in place of the real @

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

Pretty Please - add it to our Events forum(s) and add to the calendar! >>