[ QUOTE ]

Dave, Ignition timing specs for a stock mark 2 are as follows.

static- 10 btdc ( is static at resting position)

stroboscopic 15 btdc ( does this mean with a timing light?) 600 rpm

max advance 35 btdc we will say 5000 rpm

Am I correct to understand I should change to the following.

Static 12 btdc

stroboscopic 17 at 600 rpm

Max advance -should I reduce this a couple degrees below the listed 35? If so do I achive this adjustment with the vacuum control adjustig nut and a strobe light?

Or is this one of those deals were it would be best to take it to my not so local authorized Austin Healey Specialist?

[/ QUOTE ]

There are two centrifugal advance springs. The primary spring is weaker & controls initial advance up to about 2500 engine rpm. The secondary spring is stronger but has slack built into the anchor so that it does not immediately come into play. Once the slack is taken up in the secondary spring anchor, the combination of the two springs controls the advance. This gives a fast initial advance up to around 2,500 rpm & a slower advance above this rpm. There is a mechanical stop that limits maximum centrifugal advance. This combination might give something like 15 degrees at 600 rpm - static plus centrifugal, 28 degrees at 2500 rpm, & 38 degrees at 5,000 rpm.

The specs for the Tri Carb that I looked at show a static of 12 degrees & 15 degrees at 600 rpm.

Static would be at resting position where the points just open.

600 rpm would be with a timing light.

The maximum timing depends somewhat on altitude as this has a considerable effect on cylinder pressures. The higher the altitude the less the cylinder pressures & the more advance that can be used. Assuming that the distributor is calibrated reasonably well for your engine, I would just set strobe timing at 5,000 rpm for 35 to 38 degrees maximum advance (vacuum advance disconnected) & let the rest of the numbers fall where they may. If you get pinging under load, go more toward the 35 degree setting. Whenever in doubt, it's better to be slightly retarded for engine safety. Slightly rich fuel mixtures can give some extra protection against detonation. Over advanced timing will provide little power gain but a lot of engine damage. It's possible that with your cam, the primary advance could be quickened, by using a weaker primary spring to give about four degrees more advance between 600 & 2500 rpm. Maybe not worth the bother though.

Most likely, you can just set timing with a strobe to 12 to 15 degrees at 600 rpm & do a check for 35 to 38 degrees at 5,000 rpm & be pretty close. The most important number is at 5,000 rpm since you would be unlikely to hear detonation under load at this rpm. You can make minor adjustments with the knob, probably plus or minus three degrees. Greater adjustment would be done by turning the distributor body.

A perfect calibration for your particular engine & cam would need to be determined on a chassis dyno, or by extensive road testing. The maximum advance range of the distributor & the timing curve would then need to be calibrated on an old fashioned distributor machine. (Adjust primary & secondary springs plus the advance stop.)

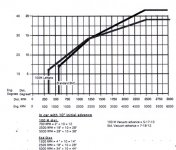

Attached is a graph of distributor advance for a higher compression engine with more radical cam, LeMans vs the lower compression engine with less radical cam to illustrate the differences.

D

Hi Guest!

Hi Guest!

smilie in place of the real @

smilie in place of the real @

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

Pretty Please - add it to our Events forum(s) and add to the calendar! >>