Jim_Gruber

Yoda

Offline

Guys spent some time in Bugsy II today taking pics and looking at quality of welding work done 33 years ago. Not happy with what I need to fix and will need advice from this team on how best to address. I 'm sure I can't get all of the pics in a single post so this may take a post or two. I'll number the pics so if you respond please refer to the picture number.

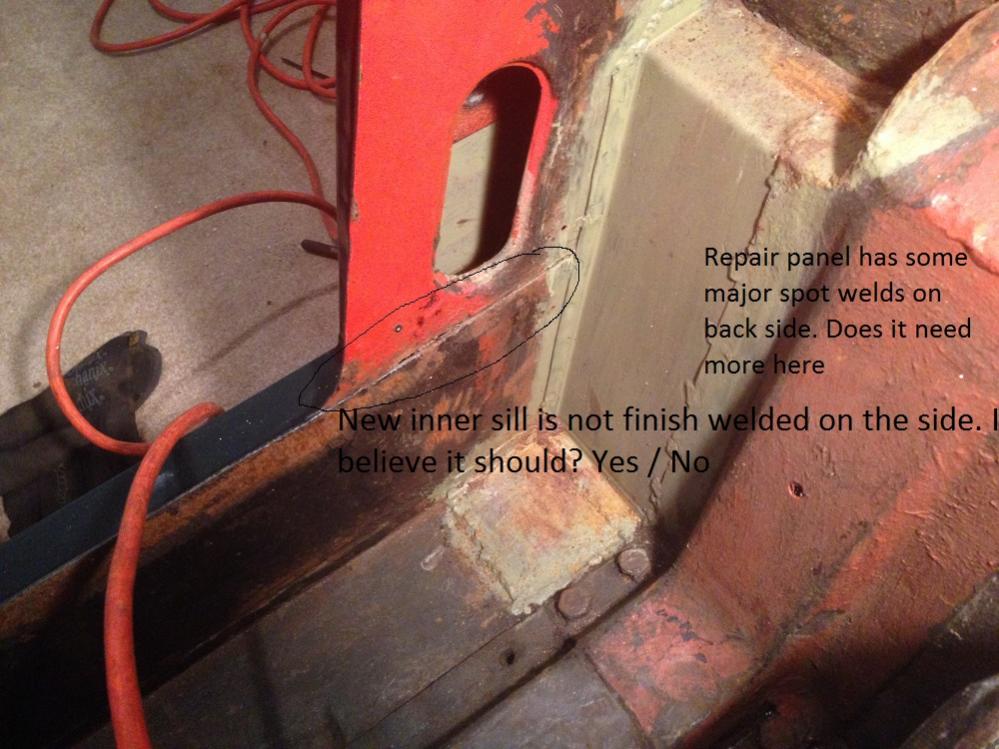

1) Passenger Side - Bulkhead Repair

Questions about the repair panel, has major spot welds 1/2" size on back side. Given the location next to spring box do I need more on this side

Inner sill now spot welded, I believe it should be. Comments

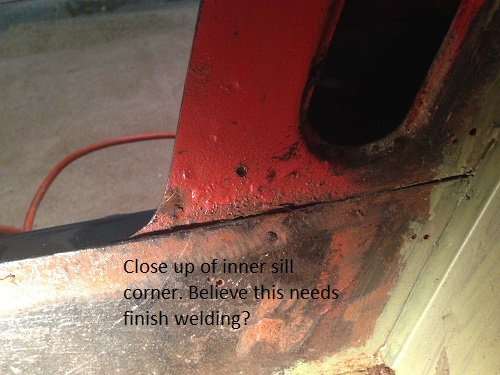

2) Closeup of inner sill - PS

3) PS Bulkhead - Bulkhead to floor gap

3)

Bulkhead is not welded and has a 3"+gap where not welded to the floor. Repair not properly done. Again this one makes me nervous seeing it is alongside the spring box. Thinking cleanup with wire wheel, try and get it shinny and then a piece of not angle iron but a fairly heavy gauge steel approx. 1 1/2 on each side to strengthen this sea mand close up.

Also of concern is some rust under reinforcement brace that goes on bulkhead floor. The vertical panel is welded at the top so I can't just pull off and nuts are really in there almost appear to be welded. A PITA to remove. How best to address. Cutting wheel and remove and replace the brace. Need some thoughts.

More to follow in next thread.

1) Passenger Side - Bulkhead Repair

Questions about the repair panel, has major spot welds 1/2" size on back side. Given the location next to spring box do I need more on this side

Inner sill now spot welded, I believe it should be. Comments

2) Closeup of inner sill - PS

3) PS Bulkhead - Bulkhead to floor gap

3)

Bulkhead is not welded and has a 3"+gap where not welded to the floor. Repair not properly done. Again this one makes me nervous seeing it is alongside the spring box. Thinking cleanup with wire wheel, try and get it shinny and then a piece of not angle iron but a fairly heavy gauge steel approx. 1 1/2 on each side to strengthen this sea mand close up.

Also of concern is some rust under reinforcement brace that goes on bulkhead floor. The vertical panel is welded at the top so I can't just pull off and nuts are really in there almost appear to be welded. A PITA to remove. How best to address. Cutting wheel and remove and replace the brace. Need some thoughts.

More to follow in next thread.

Hi Guest!

Hi Guest!

smilie in place of the real @

smilie in place of the real @

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

Pretty Please - add it to our Events forum(s) and add to the calendar! >>