Hi Roberte,

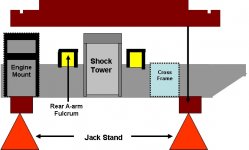

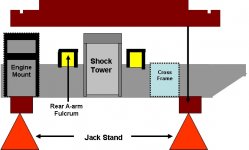

As many have said, it is a reasonably complex situation you want to address. The Healey's structure is based upon a Semi-Monoque understructure which consists of a uni-welded understructure and unstressed body panels bolted on. The main runs of the Healey's structure are formed from relatively light 15 gauge sheet metal formed into box frame runs and, because of little or no factory weather-resistant treatment, often corrodes from the inside to loose strength and continuity.

When considering repairs on the main substructures, it is not uncommon to weld a plate to fix one section of the frame and transfer the flex to cause a tare at another area. Additionally, sagging usually occurs as such supporting components as sills and dog legs and floor panels disintegrate and allow the weak center section of the door opening to allow the jams to close in at the top.

Keep in mind that the Healey's supporting structure (frame) is arched slightly, with the center section higher, to allow settling support when fully loaded. Although this arch is not obvious, it is necessary to reproduce to allow proper separation and spacing of the door jams when. I believe this will be necessary to reproduce when addressing your structural fix.

A while back, when aggressive driving my BJ8 on at a club slalom, I had torn the frame section between right rear support of the front suspension and engine mount. When repairing this section, I cut two 4X4 wood sections to allow for the proper separation and support of the frame sections to be addressed. I would create a number of additional 4x4 wooden supports to provide many more points to maintain and adjust the continuity of the frame when addressing the full extent of the understructure when applying your chosen metal fix to support/reposition the frame (i.e. bottom frame half box sections as Keoke, plates, etc.).

Ray(64BJ8P1)

Hi Guest!

Hi Guest!

smilie in place of the real @

smilie in place of the real @

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

Pretty Please - add it to our Events forum(s) and add to the calendar! >>