Johnny

Darth Vader

Offline

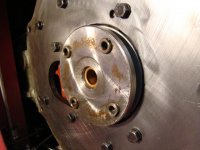

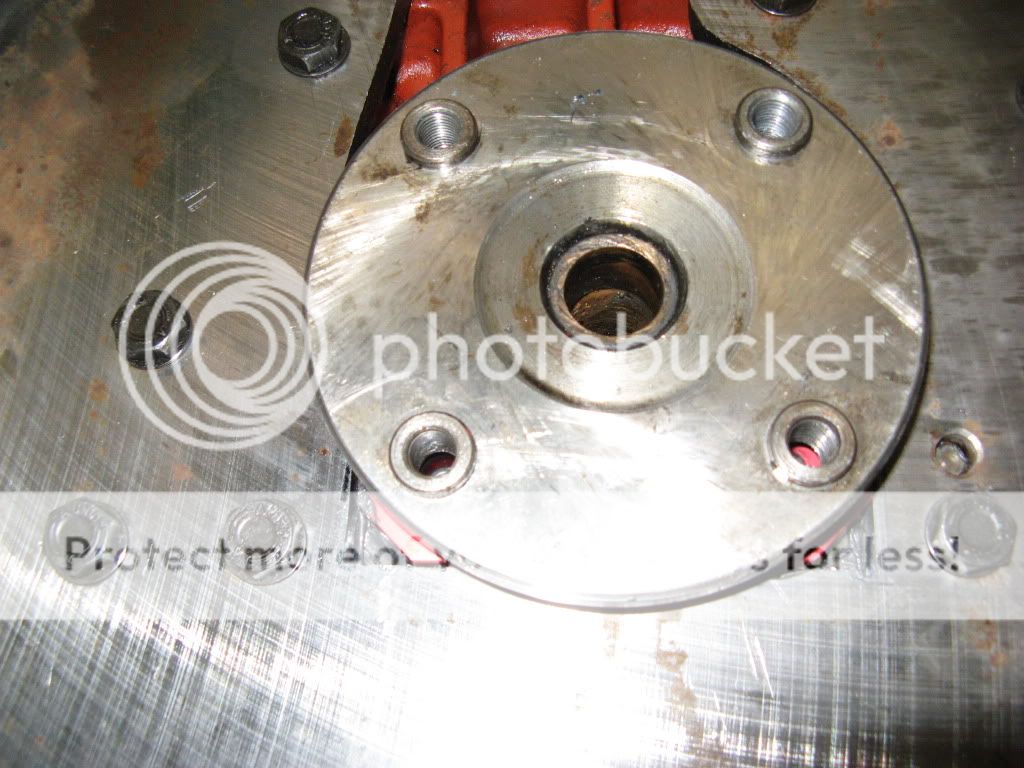

Just installed a Moss crank seal kit in my BJ7. Didn't have any problems installing it other than getting that little springy thing around the rubber seal, but I finally did get it installed. Now I have to remove some of the backing plate material in order to get it to fit. This is not easy as the backing plate is what about 3/8" thick? It's also very heavy. How did others do this?

Hi Guest!

Hi Guest!

smilie in place of the real @

smilie in place of the real @

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

Pretty Please - add it to our Events forum(s) and add to the calendar! >>

Finally finished it. Like I said, not sure it was worth all the effort but now it's done. I have to agree that this is only one area that leaks.

Finally finished it. Like I said, not sure it was worth all the effort but now it's done. I have to agree that this is only one area that leaks.